|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(3) R e p l a c e crankshaft when journals are

(6) Inspect crankshaft gear key (M, fig. 351)

grooved,

burned,

deeply

nicked,

for nicks and snug fit in keyway. Nicks

scratched, galled, scuffed, or if crank-

in key may be removed with a fine oil

s h a f t is discolored from overheating.

stone. A loose key must be replaced.

Repair minor imperfections in journals

(7) I n s p e c t

crankpin plug (MM-3) (early

by polishing with crocus cloth dipped

i n dry-cleaning s o l v e n t o r m i n e r a l

models)

for bent condition or cracks

spirits paint thinner.

around

bolt hole. Replace bent or

cracked

plugs.

(4) R e p l a c e a c r a c k e d c r a n k s h a f t o r a

167. REPAIR

c r a n k s h a f t showing evidence of wear

due to bent or twisted connecting rods.

a . Regrinding. C r a n k s h a f t s having out-of-

round bearing journals or when either connect-

b . Crankshaft Bushing-type Pilot Bearing

i n g rods or main bearing journals are worn

Replacement (fig. 337).

b e y o n d limits specified in repair and rebuild

(1) Remove damaged or worn bushing-type

s t a n d a r d s (par. 292), regrind crankshaft to a

limit of 0.010 or 0.020-inch undersize. Under-

s i z e bearing s e t s are available for rebuild.

following step A for figure 94.

The crankshaft must be held to limits established

in repair and rebuild standards and to the

(2) Install new bushing-type pilot bearing

following instructions.

( M M - 6 , fig. 322) (par. 67). Refer to

(1) S u r f a c e roughness on crankpins and

j o u r n a l s must not exceed 20 micro

168. ASSEMBLY

inches.

(2) C r a n k s h a f t must be inspected by the

Refer to figures 334 and 335 and reverse the

electro magnaflux method for fractures

sequence of instructions to assembly the crank-

and surface cracks after finishing.

shaft.

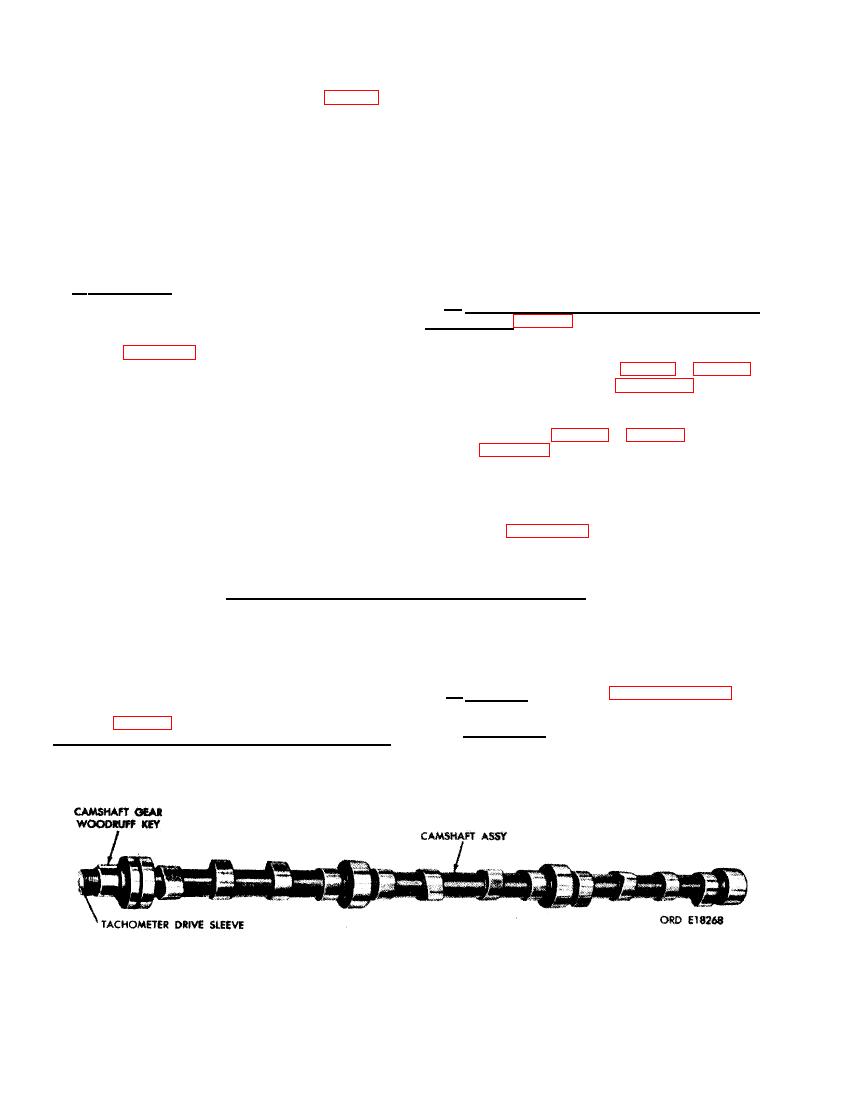

Section IV. REBUILD OF CAMSHAFT ASSEMBLY AND THRUST PLATE

169. DISASSEMBLY

The only component part removed from the

a . Cleaning. Refer to paragraph 152 for

camshaft assembly is the camshaft gear Wood-

general cleaning procedures.

ruff key (fig. 338). The tachometer drive sleeve

--. I n s p e c t i o n .

b

is a press fit in the end of the camshaft and

is not removed unless it is damaged.

(1) Camshaft. Inspect camshaft (AM, fig.

208

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |