|

|||

|

|

|||

|

Page Title:

Section III. REBUILD OF CRANKSHAFT ASSEMBLY |

|

||

| ||||||||||

|

|

Section III. REBUILD OF CRANKSHAFT ASSEMBLY

visible inside the crankpin holes as shown in

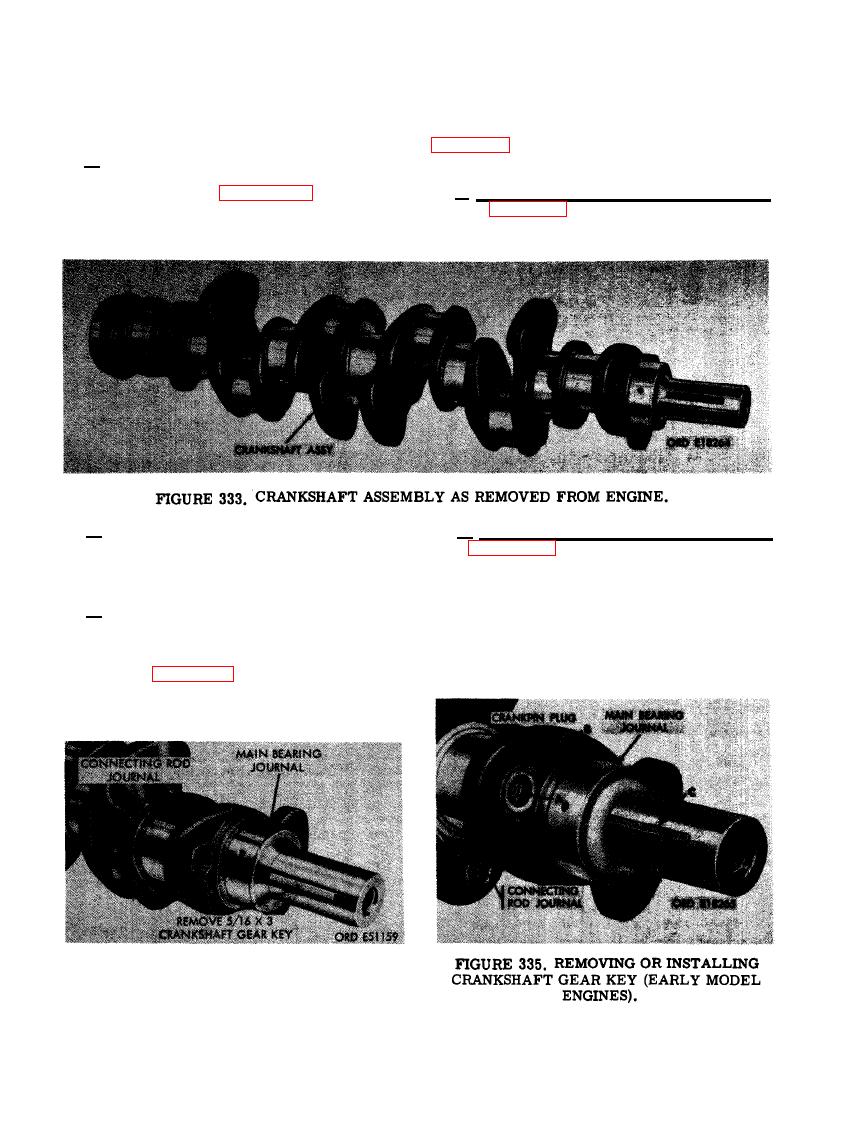

164. GENERAL

a . This section covers disassembly, clean-

165. DISASSEMBLY

ing, inspection, repair, and assembly of the

crankshaft assembly. Figure 333 illustrates a

a. Late Model Engine Crankshaft Assembly.

crankshaft assembly as removed from the en-

Refer to figure 334 and disassemble the crank-

gine.

shaft assembly.

b. Late model engines, serial Nos. 5261 and

b . Early Model Engine Crankshaft Assem-

up, have a crankshaft in which the drilled oil

bly. Figure 335. (A) Remove six 1/16 x 3/4

passages do not enter the crankpin journal bore,

cotter pins, 1/4-inch slotted nuts, and 1/4 x

eliminating the need for crankpin plugs.

3-3/8 cap screws. (B) Remove 12 crankpin

plugs. (C) Remove 5/16 x 3 crankshaft gear

c . Early model engines, serial Nos. 1001

key.

through 5260 are equipped with a crankshaft

which utilizes connecting rod journal crankpin

plugs. The journals have drilled oil passages

as shown in figure 336. Crankpin plugs seal the

connecting rod journal bores at the ends, main-

taining a pressurized lubrication system. Early

model crankshafts are identified by oil passages

CRANKSHAFT GEAR KEY (LATE MODEL

ENGINES).

206

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |