|

|||

|

|

|||

|

Page Title:

Section V. REBUILD OF PISTONS, RINGS, PISTON PINS, AND CONNECTING RODS |

|

||

| ||||||||||

|

|

322) for cracks using magnaflux equip-

evidence of wear. Refer to figure 514,

ment. When magnaflux equipment is not

repair and rebuild. If plate is grooved

available use a magnifying glass and a

or worn excessively, replace.

strong light. Inspect camshaft lobes and

bearing surfaces for wear, scuffing,

and scoring. Check camshaft against

limits specified in repair and rebuild

standards (par. 292). Inspect camshaft

a . Repair. No repairs can be made to the

for stripped or damaged threads. Check

camshaft (AM-2, fig. 322) except for the removal

keyway for damage.

of minor scratches and nicks from camshaft

lobes and bearing contact surfaces. Remove

(2) Woodruff key. Inspect camshaft gear

minor scratches and raised metal surfaces using

Woodruff key (fig. 338) for nicks and

crocus cloth soaked in mineral spirits paint

for snug fit in keyway. A damaged key,

thinner or a fine mill file. Replace camshaft as-

or loose fitting key, will be cause for

sembly when bearing surfaces fail to meet re-

replacement of key or camshaft.

pair and rebuild standards (par. 292) or when

camshaft lobes are excessively damaged or

(3) Tachometer drive sleeve. Inspect tacho-

worn. Slight nicks and scratches can be removed

meter drive sleeve (AM-1, fig. 322) in

from the camshaft thrust plate using crocus

front end of camshaft. Check for cracks

cloth soaked in mineral spirits paint thinner.

or rounded edges on drive slot. A dam-

Lay crocus cloth on a flat surface and polish

aged or loose fitting sleeve will be

thrust plate as necessary until slight nicks and

cause for replacement of camshaft.

scratches are removed.

(4) Camshaft thrust plate. Inspect face of

b. Assembly. Refer to figure 338 and install

camshaft thrust plate (AL, fig. 322) for

camshaft gear Woodruff key.

Section V. REBUILD OF PISTONS, RINGS, PISTON PINS, AND CONNECTING RODS

172. GENERAL

This section covers the disassembly, clean-

ing, inspection, repair, and assembly of the

pistons, rings, piston pins, and connecting rods.

173. DISASSEMBLY

Note. Before removing piston rings, check

to see if rings are free in the piston ring grooves.

Mark sticking rings for further detailed inspec-

tion. Mark all rings so they can be identified

with the piston grooves from which they were

removed. If rings are reused, install rings in

their original location.

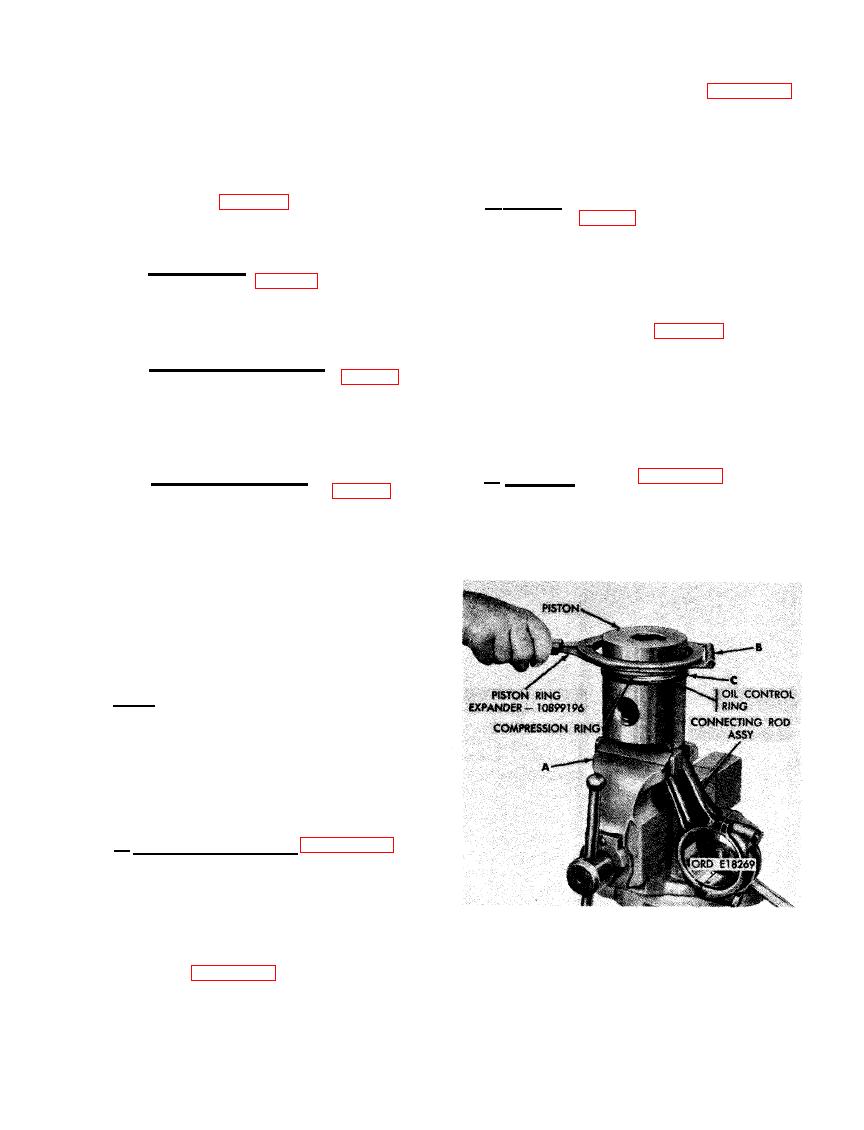

a . Remove Piston Rings. Figure 339. (A)

Place connecting rod and piston assembly in a

soft-jawed vise. (B) Remove top compression

piston r i n g using piston ring expander -

10899196. Remove remaining two compression

rings in same manner. (C) Remove oil control

ring using piston ring expander - 10899196. Re-

move oil control ring expander spring following

PISTON RINGS USING PISTON RING

instructions in figure 340.

EXPANDER - 10899196.

209

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |