|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

cylinder head assembly when found unservice-

Note. After the three fuel injector

able.

nozzle and holder assemblies are re-

moved from cylinder head, test nozzle

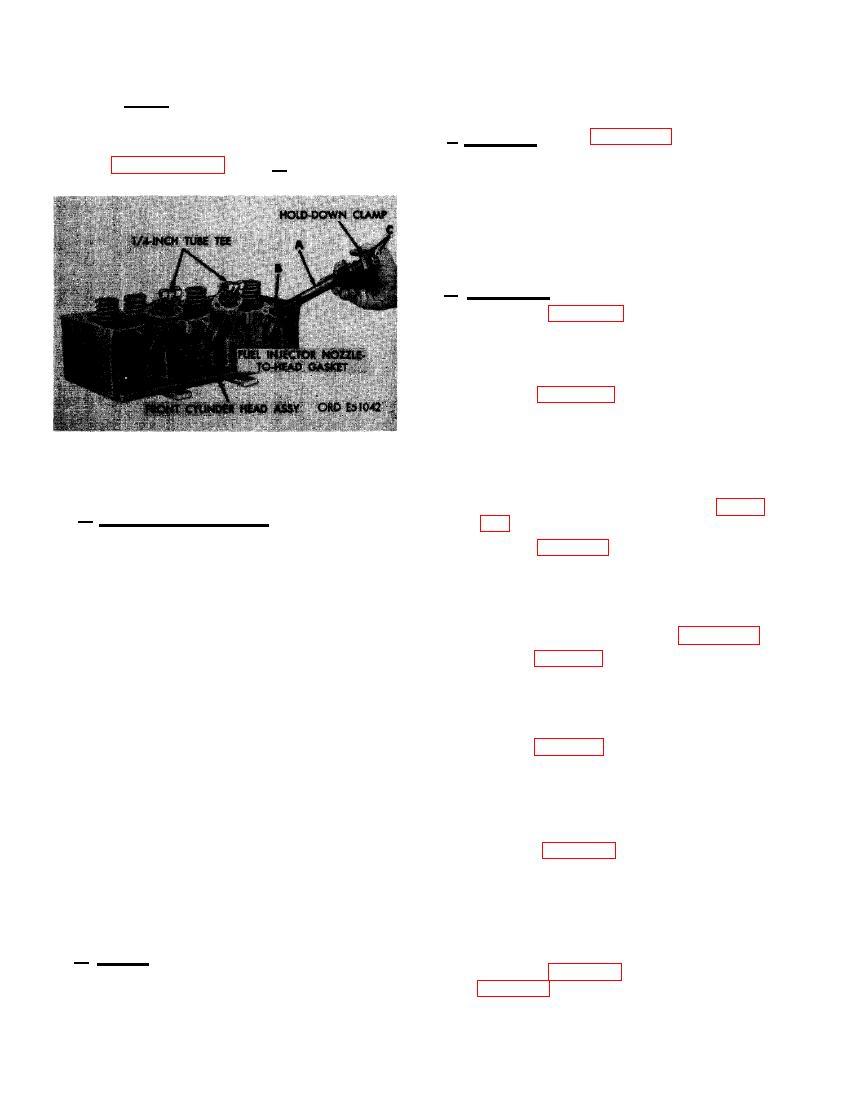

f. Assembly. Refer to figures 193 and 194 and

and holder spray pattern as directed in

reverse the sequence of illustrations and in-

paragraphs 83c and d.

structions to assemble the front cylinder head

assembly. Use a new fuel injector nozzle-to-

head gasket. Hold gasket in place at nozzle end

by applyng a light coating of grease. This in-

sures proper gasket seating and prevents gas -

ket from sliding off end of nozzle and holder

assembly during installation.

g. Installation.

(1) Refer to figures 190 through 192 re-

verse the sequence of illustrations and

instructions to install cylinder head gas-

ket and the front cylinder head assembly

and tighten nuts in the sequence out-

lined in figure 195. Install the new head

gasket properly.

Note. Stud threads must be lubricated

with OE 10 oil to obtain proper torque

reading.

FUEL INJECTOR NOZZLE AND

HOLDER ASSEMBLIES.

(2) Torque tighten front cylinder head nuts

with special wrench as shown in figure

d. Cleaning and Inspection.

(1) Clean cylinder head assembly thor-

(3) Refer to figure 189 and reverse the se-

oughly using dry-cleaning solvent or

quence of instructions to install the

mineral spirits paint thinner. Remove

front set of rocker arms and to connect

hard carbon deposits using a wire brush

fuel injector nozzle fuel return tubes.

or scraper.

(4) Adjust valve clearance following in-

Note. When cylinder head gasket shows

structions which accompany figure 183.

signs of leaking or having been blown,

(5) Refer to figure 62 and reverse the se-

inspect cylinder head closely for dam-

quence of instructions to install front

age.

cylinder head cover gasket and cover.

(2) Inspect cylinder head assembly for

Install new gaskets under cover and

cracks around valve seats and for dam-

breather adapter.

aged gasket surface. Check for evidence

(6) Refer to figures 168 through 172 and re-

of cracked or warped intake and ex-

verse the sequence of illustrations and

haust valves. Replace cylinder head as-

instructions to install the intake, ex-

sembly when cracked or when valve

haust, and cylinder head water outlet

seats show evidence of burning. Check

manifolds as an assembly. Install new

threads on studs and in tapped holes for

manifold gaskets.

good condition. Core hole plugs must be

tight and not show signs of coolant

(7) Refer to figures 44 through 47 and 49

leakage.

through 52 and reverse the sequence

of illustrations and instructions to in-

Note. Thermo fatigue cracks found at

stall the turbosupercharger assembly.

bridge between valve seats are not cause

to reject a head unless coolant leakage

Install new gaskets and check hoses for

serviceable condition. Oil inlet tube and

is evident.

outlet hose connections must be tight.

e. Repair. Replace all studs having stripped

(8) Refer to figure 57, steps C and D and

threads. Repair all damaged threads in tapped

holes using a good used tap. Remove small

quence of instructions to connect fuel

scratches and raised metal from gasket surface

using emery cloth or fine mill file. Replace

injector tubes to nozzle assemblies. Re-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |