|

|||

|

|

|||

|

Page Title:

DRIVE BELTS |

|

||

| ||||||||||

|

|

coloration, wear, pitting, and evidence

of pounding. Defective parts are cause

for replacement.

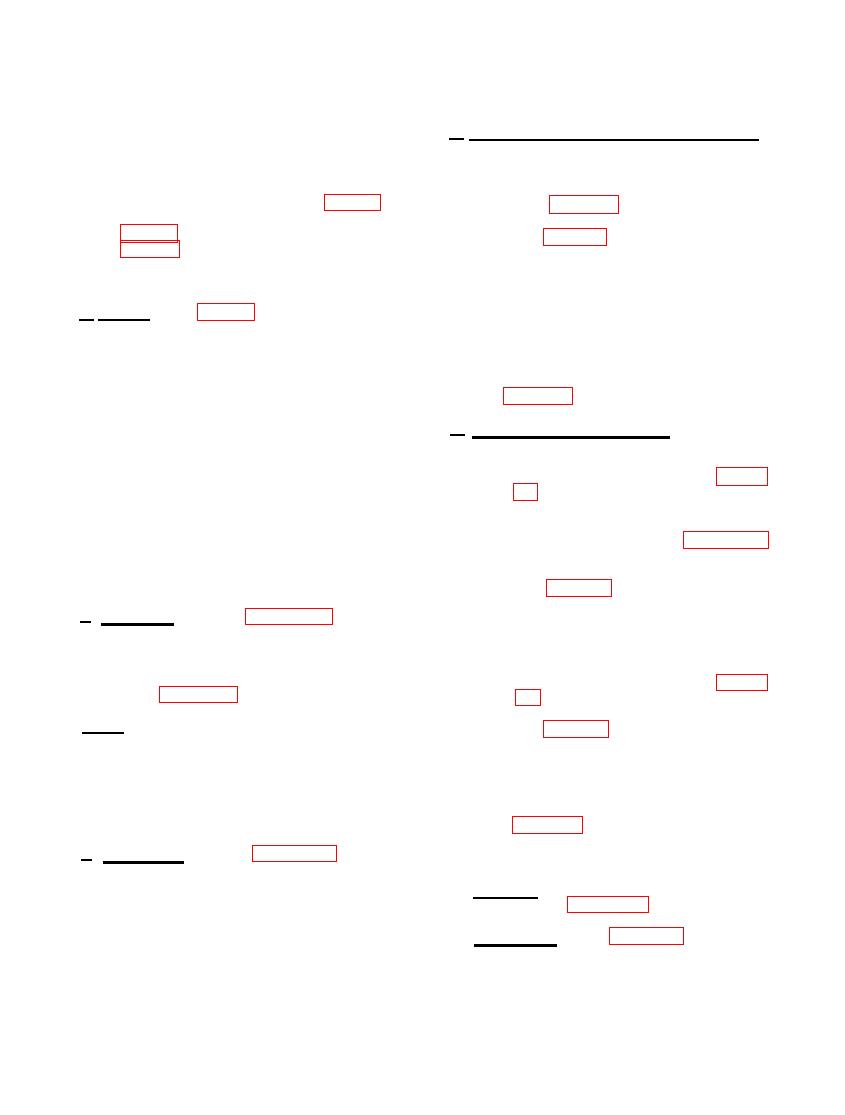

a. Engine Fan and Generator Drive Belts.

(2) Inspect nozzle spring (G) for cracks and

evidence of wear.

(1) Remove engine ran and generator drive

belts following instructions which ac-

(3) Check nozzle cap nut threads (fig. 157),

company figure 41.

fuel injector tube connection threads

(2) Refer to figure 41 and reverse the se-

quence of instructions to install engine

and holder assembly when these threads

fan and generator drive belts.

are stripped or damaged beyond repair.

Note. When one engine fan and genera-

h. Repair (fig. 156). Repair of defective

tor drive belt is worn or broken, re-

parts is limited to the reconditioning of dam-

place both belts.

aged threads and the lapping of the valve (C-1)

to the valve nozzle body (C-2). Repair damaged

(3) Adjust engine fan and generator drive

threads, and lap the valve in the body to re-

belt deflection following instructions in

move minor discolorations. Replace parts show-

in figure 43.

ing wear, pounding, or pitting. Replace the noz-

zle assembly if the spray holes are oversize

b. Air Compressor Drive Belt.

or if they cannot be freed of obstructions. Re-

place nozzle assembly when lapped sealing sur-

(1) Remove engine fan and generator drive

face of body (B) is badly scratched or nicked

belts following instructions for fig-

or when polishing on a lapping plate does not

ure 41.

remove the defects. Remove minor scratches

from sealing surface with fine compound on a

(2) Remove air compressor drive belt fol-

lapping plate. The nozzle body (B) must be

lowing

instructions for figures 80

held flat on the lapping plate during this opera-

through 82.

tion. Replace nozzle body if locating dowel pin

is loose or damaged.

(3) Refer to figures 80 through 82 and re-

verse the sequence of illustrations and

i. Assembly. Refer to figures 152 through

instructions to install air compressor

155 and reverse the sequence of illustrations

drive belt.

and instructions to assemble the fuel injector

nozzle and holder assemblies. Test nozzle and

(4) Adjust air compressor drive belt de-

holder assembly after assembly following in-

flection following instructions for fig-

structions for figure 151.

ure 87.

Note. The fuel injector nozzle and holder

(5) Refer to figure 41 and reverse the se-

assmbly is precision manufactured and as-

quence of instructions to install engine

sembly requires special precautions. The noz-

fan and generator drive belts.

zle must be clean and free of any grease

deposits or finger stains. Store nozzle and

(6) Adjust engine fan and generator drive

holder assembly in a suitable container to pre-

belt deflection following instructions

vent entrance of dirt.

for figure 43.

j. Installation. Refer to figures 148 through

150 and reverse the sequence of illustrations

and instructions to install the fuel injector noz-

a. Removal. Remove engine fan following

zle and holder assemblies. Use a new fuel in-

the instructions for figure 112.

jector-to-nozzle gasket. Hold gasket in place

at nozzle end by applying a light coating of

b. Installation. Refer to figure 112 and re-

grease around gasket. Torque the hold- down

verse the sequence of instructions to install

clamp cap screws to 150 to 175 pound inches.

the engine fan.

112

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |