|

|||

|

|

|||

|

Page Title:

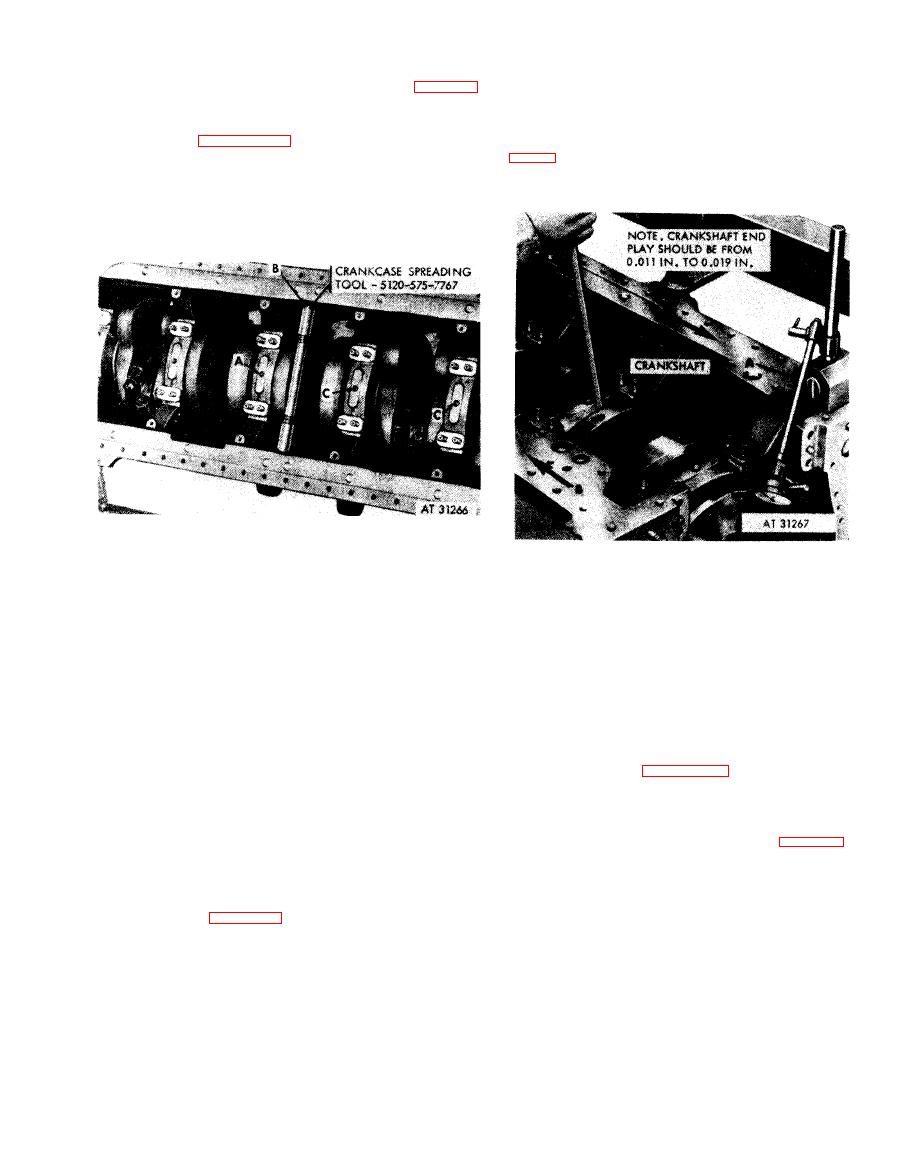

Figure 7-2. Installing main bearing caps using crankcase spreading tool-5120-575-7767. |

|

||

| ||||||||||

|

|

Note. End play should be from 0.00740 to

0.019-inch. When end play exceeds 0.019-inch,

180.

remove bearing caps and crankshaft. Install

c.

Crankshaft

and

Connecting

Rod

Assembly.

bearing

cap

and

recheck

thrust

bearing

bore

Refer to figures 5-179 through 5-175 and to the

instructions given in (1) through (3), below.

end play to make sure it is within limits.

(1) Main bearing caps. Coat outer edges

of the bearing cap and machined surfaces of the

crankcase webs with

engine

oil

to

facilitate

installation of caps.

1. Install number 4 (center) thrust bearing cap (A) and

bearing half in position on crankcase studs (tie rods).

Use crankcase spreading tool (B)-5120-575-7767 to

1. Mount a dial indicator (A) on crankcase so indicator

spread crankcase so bearing caps will slide over studs

point contacts drive gear flange on crankshaft.

and into position in the crankcase.

2. Using a heavy duty screwdriver, wedged between main

bearing cap and crankshaft counterweight, push

Note.

Be sure main bearing caps and

crankshaft toward front end (B) of crankcase.

main bearing halves are installed in their original

3. Set indicator (C) on zero reading ("0").

positions

according

to

location

number

iden-

4. Using heavy duty screwdriver, push crankshaft toward

tification on the cap and bearing half.

the rear (D) of crankcase and check indicator end play

reading.

2. Install the remaining six bearing halves in caps (C) and

similarly install caps and bearings in crankcase.

(3) Main

bearing

attaching

parts.

Note. The side of each main bearing cap

(a) Refer to figure 5-173 and install all

identified as "fly end" must be installed toward

main bearing cap plate washers and nuts. Do not

flywheel end or rear of engine.

torque tighten nuts at this time. Check and

record the height of each stud using a flat surface

using crankcase spreading tool-

plate and dial indicator as shown in figure 7-4.

5120-575-7767.

(2) Crankshaft end play. C h e c k c r a n k s h a f t

end play following the instructions which ac-

company figure 7-3.

7-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |