|

|||

|

|

|||

|

Page Title:

SectioN II. ASSEMBLY OF ENGINE FROM SUBASSEMBLIES |

|

||

| ||||||||||

|

|

Section

Il.

ASSEMBLY

OF

ENGINE

FROM

SUBASSEMBLIES

maintenance and overhaul stand - 4910-856-

General

4137 (fig. 6-8) and rotate stand so that oil pan

This section covers the assembly of the engine

flanges are up.

from subassemblies. Components are grouped

Starter

Drive

Gearshaft,

Generator

together in proper assembly order. The crank-

and Idler Gears, Piston Oiler

case assembly was partially assembled during

Nozzles, and Crankshaft and Connect-

rebuild of engine components (Chapter 6).

ing

Rod

Assembly

Normally the crankcase assembly will be on the

overhaul stand after it has been inspected and

Refer to Table 7-1 for illustrations and as-

the main bearing bosses have been checked. In

sembly instructions. References are listed in the

table.

case

crankcase

is

not

on

stand,

install

on

Piston Oiler Nozzles, and Crankshaft and Connecting

Rod Assembly

Reference

Component

Starter Drive Gearshaft and Generator and Starter Idler

Gears

Piston Oiler Nozzles and Crankshaft and Connecting Rod

5-173, 7-4, 5-172, 5-171

Assembly

a. Starter Drive Gearshaft and Generator and

183, and 5-181 and to the instructions given in

(1) and (2), below.

(1) Starter drive gearshaft bearing cage.

There are two types of bearing cages being used

on the engine. Early bearing cages have a flush

mounting face and require the use of a sealent.

Late bearing cages have a machined recess to

accommodate a preformed packing. When

overhauling an engine, do not attempt to use a

preformed packing on a bearing cage that does

not have a machined groove to accommodate the

packing.

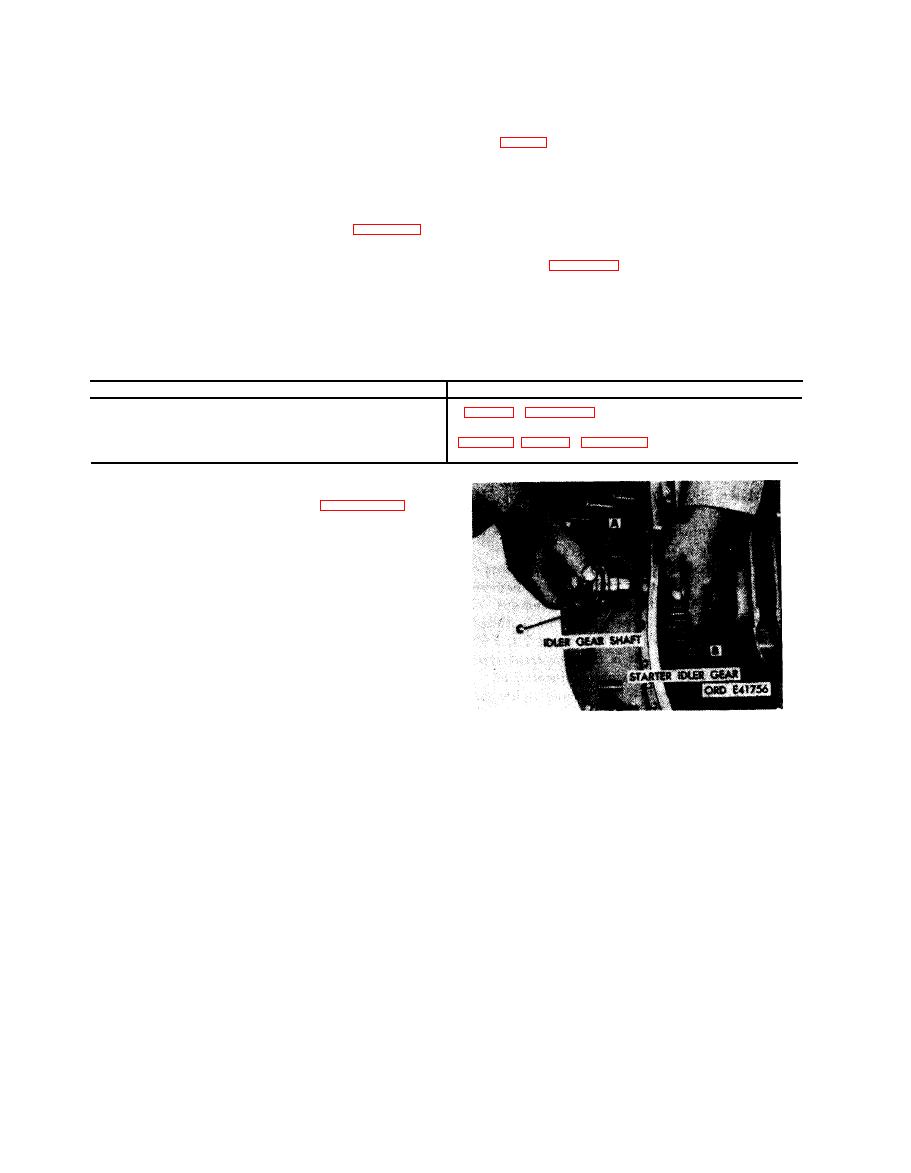

1. Install new preformed packing (A) on idler gearshaft

(2) Generator and starter idler gears. I n s t a l l

(C).

generator idler gear and assembled ball bearing

2. Position starter idler gear (B) and a line with idler

retaining ring toward rear of crankcase in the

gearshaft bore in crankcase.

same manner as the starter idler gear.

Note. Retaining ring securing ball bearing

in starter idler gear must be toward rear of

crankcase when idler gear is positioned in crank-

case.

7-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |