|

|||

|

|

|||

|

Page Title:

Section VI. REBUILD OF MISCELLANEOUS ENGINE COMPONENTS |

|

||

| ||||||||||

|

|

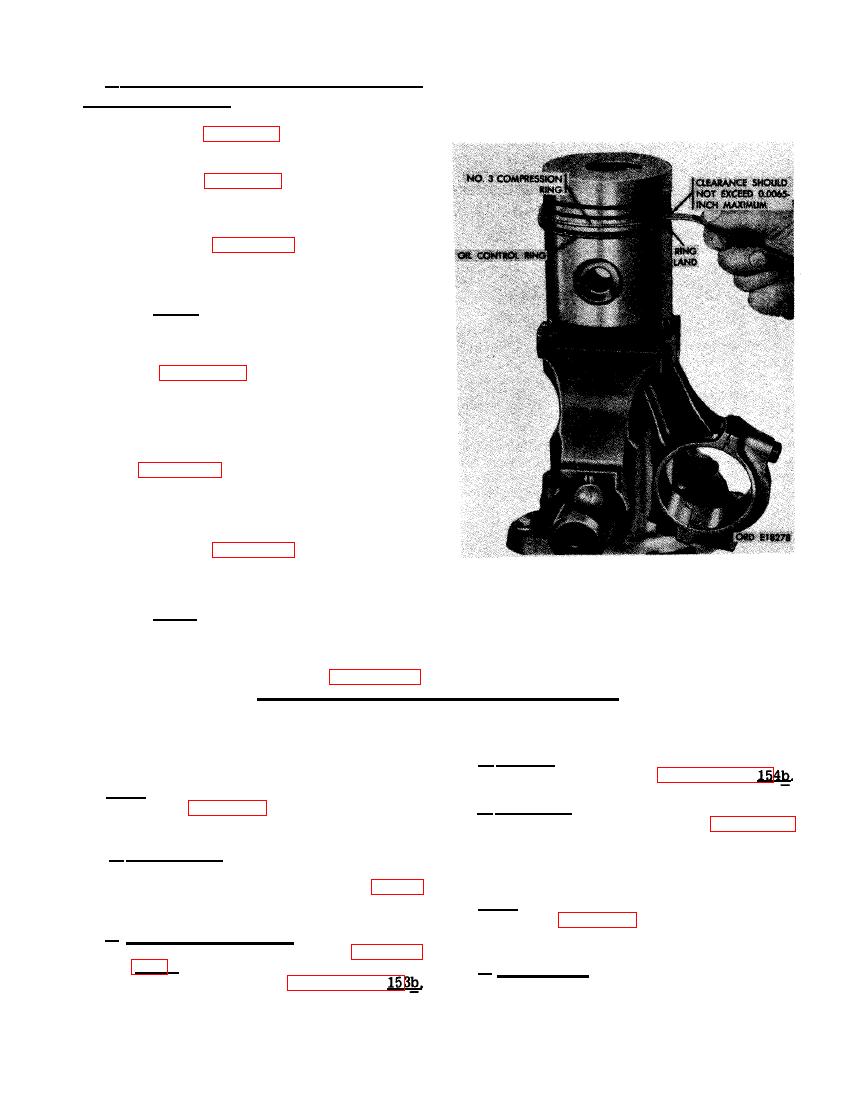

c. Installing Piston Oil Control Ring and No.

3 Compression Ring.

(1) Refer to figure 340 and install oil control

expander spring as shown.

(2) Refer to figure 339 and install oil control

ring u s i n g piston ring expander -

10899196.

(3) Refer to figure 339 and install No. 3

compression ring using piston ring

expander - 10899196.

N o t e . No. 3 compression ring is

marked "TOP" on one face and this

side is installed toward head of piston.

The face of the ring is tapered as shown

in figure 344. The other piston rings

are not marked.

(4) Check No. 3 compression ring clear-

ance between ring and ring land on

piston using a feeler gage as shown in

0.0065-inch. When excessive clearance

exists, piston ring lands are worn and

piston should be replaced.

(5) Refer to figure 339 and install No. 1

and No. 2 compression rings as shown

using piston ring expander - 10899196.

N o t e . The clearance between No. 1

and No. 2 compression rings and ring

SION RING CLEARANCE USING A

lands on piston cannot be accurately

FEELER GAGE.

checked because piston rings and ring

grooves are tapered. See figure 344.

Section VI. REBUILD OF MISCELLANEOUS ENGINE COMPONENTS

c . Repair. Repair crankshaft rear oil seal

housing (DD) as directed in paragraph

Note. The key letters shown below in paren-

theses refer to figure 322 except where other-

d. Assembly. Install new crankshaft rear oil

wise indicated.

seal (CC) following instructions for figures 166

and 167.

a. Disassembly. Remove crankshaft rear oil

seal (CC) from oil seal housing (DD) using a

suitable drift following instructions for figure

165. Discard seal.

Note. The key letters shown below in paren-

theses refer to figure 322 except where other-

b. Cleaning and Inspection. Thoroughly clean

wise indicated.

crankshaft rear oil seal (CC) as directed in para-

graph 152e. Inspect crankshaft rear oil seal

a. Disassembly. Disassembly of the air com-

housing (DD) as directed in paragraph

pressor support assembly (B) is limited to re-

215

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |