|

|||

|

|

|||

|

Page Title:

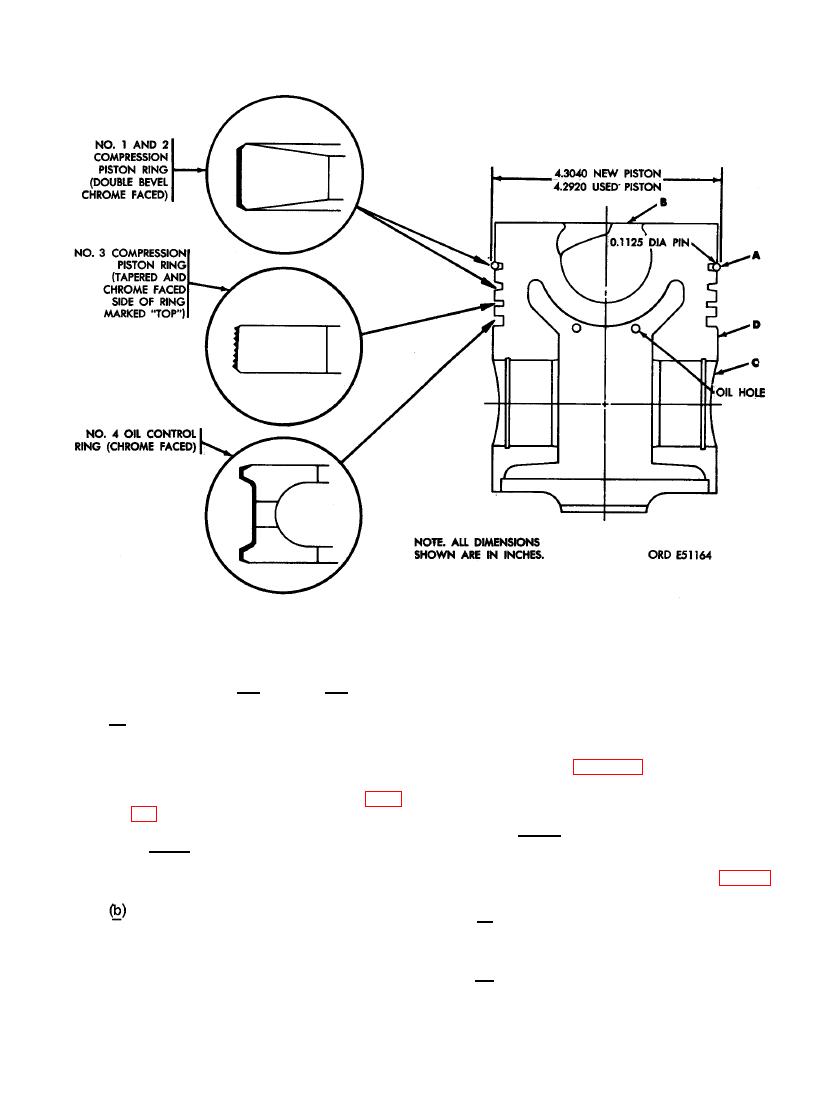

FIGURE 344. INSPECTION POINTS FOR PISTON. |

|

||

| ||||||||||

|

|

be sticking in piston ring grooves. Check

lower rings using a feeler gage. Push

side clearance of rings in piston grooves

rings into groove as far as possible

as described in (a) through (d) below.

and insert feeler gage, by trial, until

one is found that will enter this area

(a) Check side clearance (ring width) on

with a slight drag. Check the thickness

No. 1 and 2 top compression rings by

dimensions of this gage against the

measuring the thickness of the ring

limits specified in repair and rebuild

at the outer edge. Check the dimen-

standards (par. 292). Mark all rings

sion against the limits specified in

for replacement that are not within

repair and rebuild standards (par.

limits specified.

Note. The third compression ring

Note. These rings must be checked

and oil control ring side clearance

must also be checked after rings are

i n this manner because they are

tapered.

installed on piston as shown in fig-

ure 348.

The side clearance of the third com-

(c) E x c e s s i v e side clearance may be

pression ring and oil control ring can

caused by the rings being worn or

be checked by installing them in their

by piston ring groove wear.

proper locations on the piston using

piston ring expander - 10899196. Mea-

(d) Less than normal clearance indicates

sure the side clearance of these two

a broken or damaged ring land.

212

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |