|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

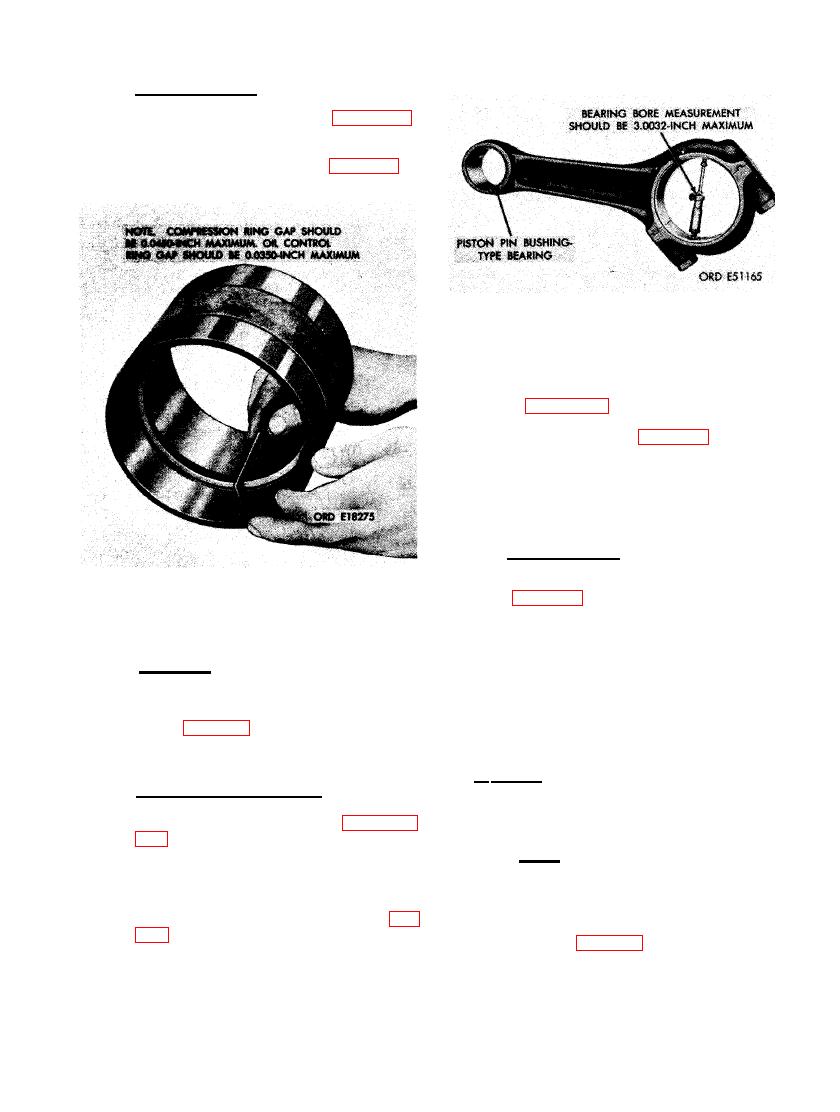

(3) Piston ring gap. Measure end gap of

all rings by placing rings in compres-

sor - 10899159 as shown in figure 345.

Mark for replacement all rings that do

not conform to limits specified in re-

pair and rebuild standards (par. 292).

BEARING BORE USING MICROMETER.

in figure 346. Check this measurement

against limits specified in repair and

rebuild standards (par. 292). Remove

connecting rod bolts, cap, and bearing

halves and check the contact surface as

indicated by Prussian blue transfer.

Replace bearings that do not make at

least 75 percent of total contact.

(6) Connecting rod. Check connecting rod

and cap (SS-2 and SS-5) against limits

specified in repair and rebuild standards

for twisted or bent condition using suit-

USING PISTON RING COMPRESSOR -

able checking tools. Inspect piston pin

10899159.

bushing-type bearing bore for confor-

mation to tolerances specified in repair

(4) Piston pin. Inspect piston pin (XX) for

and rebuild standards and for pitting,

wear, c r a c k s , nicks, or scratches.

galling, scoring, or discoloration. Mark

Check diameter of pins against limits

damaged or worn bearing for replace-

specified in repair and rebuild stan-

ment.

dards (par. 292). Replace unserviceable

pins. Replace cracked or unserviceable

piston pin retaining rings.

a . Piston.

(5) Connecting rod bearings. Inspect con-

(1) Replace uny piston (YY) which is cracked

necting rod bearing halves (SS-4) in the

or distorted, or when it shows evidence of

same manner as described in paragraph

flaws in spherical combustion chamber.

Apply a thin coating of Prussian blue

Note. Spherical combustion chamber

to the backs of the connecting rod bear-

lip cracks under 3/4" in length and are

ing halves and install the bearing halves

not cause for replacement.

in their respective connecting rod and

(2) Replace pistons which are not within

cap according to location markings (fig.

limits specified in repair and rebuild

standards (par. 295).

connecting rod bolts to a torque of 800

pound inches. Check bearing inside dia-

(3) Replace pistonswhich are cracked, worn,

meter, using a micrometer, as shown

or abraided in the piston pin bore.

213

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |