|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

d. Connecting Rod Sleeve Bearing Halves.

(4) Replace piston if oil holes in ring lands

Replace all connecting rod sleeve bearing halves

cannot be cleared or if lands are dam-

(SS-4) that do not check within limits specified

aged or broken.

in repair and rebuild standards (par. 292) or

when bearings do not show at least 75 percent

(5) Replace pistons which are badly burred,

contact by Prussian blue transfer after bore

nicked, or scratched. Remove minor

check (par. 174b(5), above).

burs, nicks, or scratches from pistons

with crocus cloth dipped in dry-cleaning

solvent or mineral spirits paint thniner.

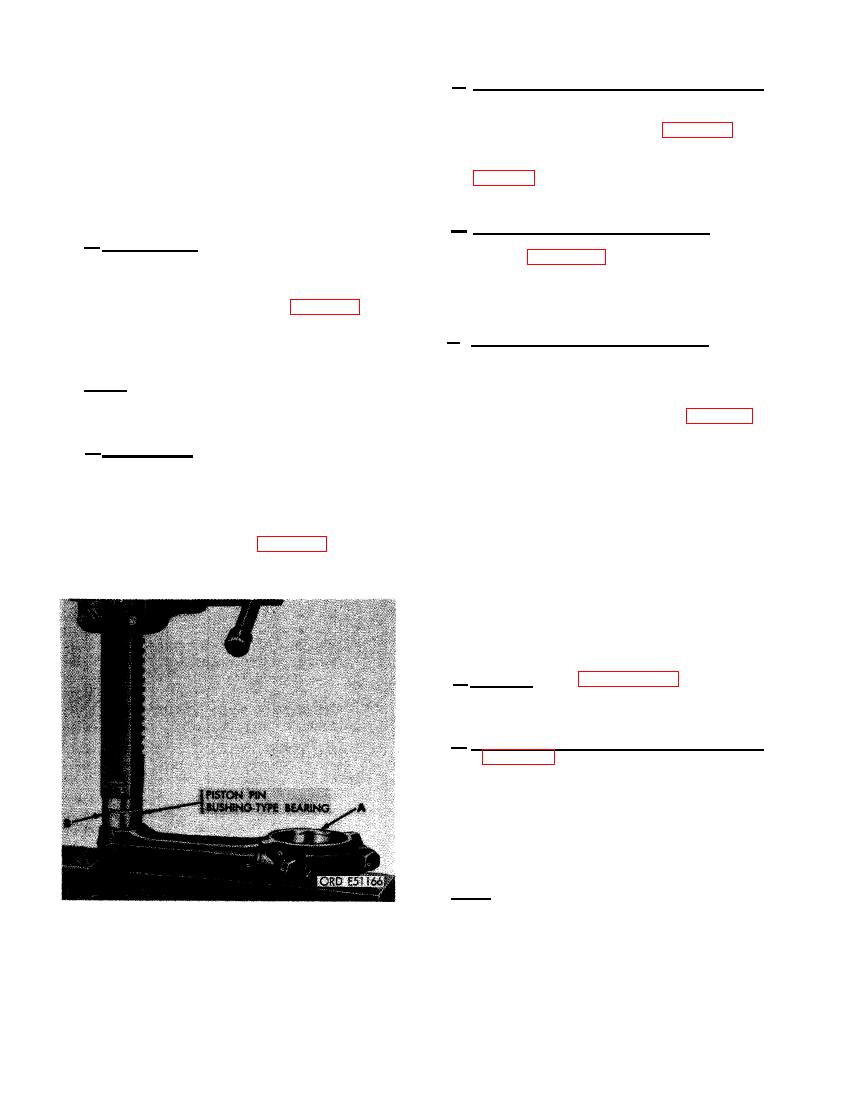

e . Piston Pin Bushing-type Bearings. Re-

place worn or damaged piston pin bushing-type

b. Piston Rings. Replace rings (SS, TT, and

bearing (SS-1). Figure 347. (A) Position con-

UU) that are scuffed, scored, chipped, or

necting rod on suitable supports as shown. Bore

scratched or when they show signs of abrasion.

new bushing to 1.6265 to 1.6267-inches.

Replace rings when not within limits specified

in repair and rebuild standards (par. 292) for

side clearance in piston grooves and for end

f. Connecting Rods, Caps, and Bolts.

gap. Replace oil control rings if oil drain holes

cannot be cleaned.

(1) Replace connecting rod assemblies (SS)

Note. Piston rings cannot be repaired. If a

which are not within limits specified in

ring must be replaced, replace all rings on that

repair and rebuild standards (par. 292).

piston.

Rods with damaged piston pin bushings

c . Piston Pins. Replace piston pins (XX)

can be repaired as outlined in e above.

w h i c h are cracked or have deep nicks or

scratches. Remove minor nicks or scratches

(2) Replace rod cap bolts (SS-6) that have

with crocus cloth dipped in dry-cleaning solvent

damaged threads.

or mineral spirits paint thinner. Replace piston

pins which are not within limits specified in re-

pair and rebuild standards (par. 292). Replace

(3) Replace b o l t s that are cracked,

cracked or damaged piston pin retaining rings

scratched, or that show any evidence

(WW).

of stretching.

176. ASSEMBLY

a . General. Refer to paragraph 156 for as-

sembly instructions.

b. Assemble Pistons and Connecting Rods.

Refer to figures 341 and 342 and reverse the se-

quence of illustrations and instructions to as-

semble the piston and connecting rods. The

number stamped on top of piston, must cor-

respond with numbers marked on connecting rod

and rod cap. The number on piston must be on

the same side as rod marks.

Note. Lubricate piston pins, piston pin bore

in piston, and piston pin bushing-type bearing

in connecting rod with engine oil OE-10 (MIL-

0-2104) during assembly.

PISTON PIN BUSHING-TYPE BEARING.

214

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |