|

|||

|

|

|||

|

Page Title:

Repair of Fuel Injection Pump Housing |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

(2) Refer to figure 3-105 and install bearing

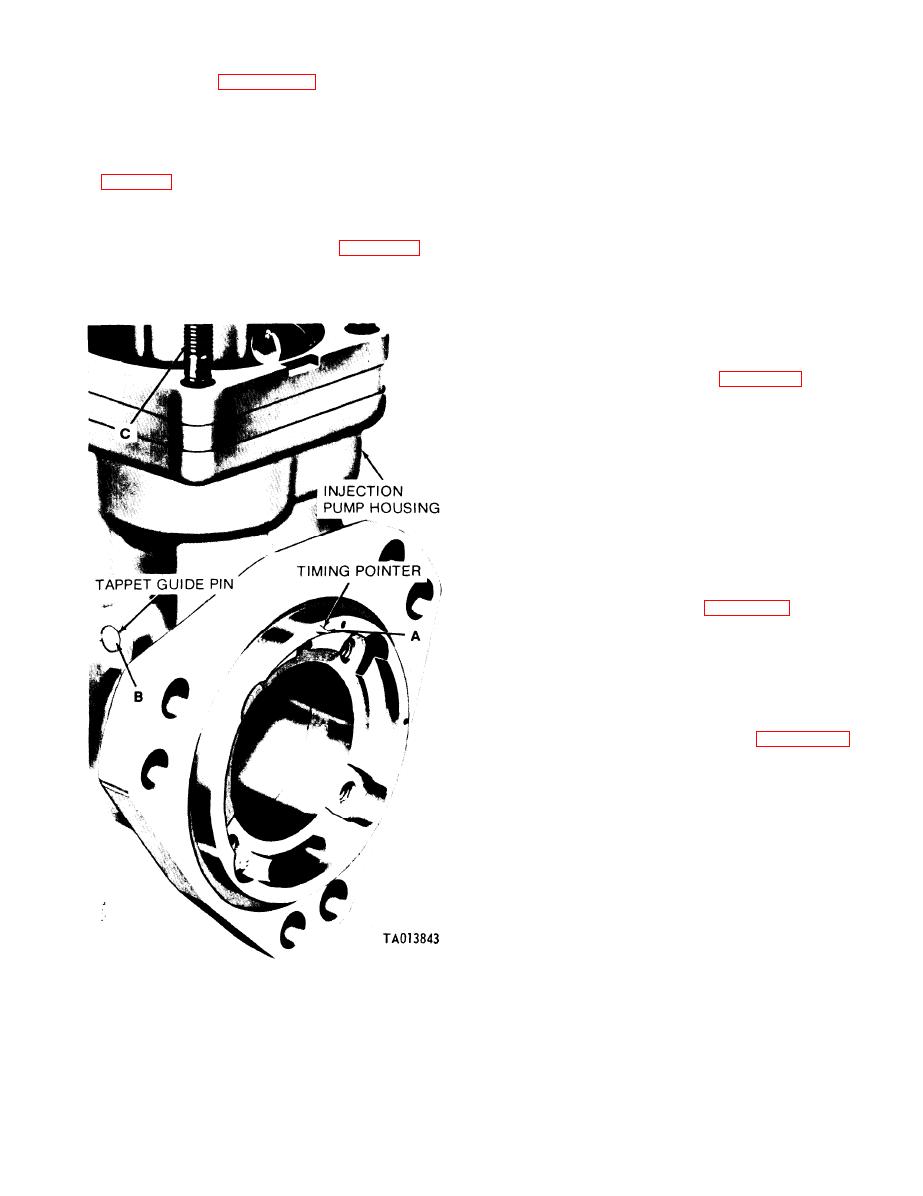

b. Examine the timing pointer (A), tappet guide

retaining locknut and related parts on camshaft.

pin (B), and studs (C) for wear and damage. If any

Torque tighten nut to 25-40 foot-pounds. Secure nut

part is defective replace the pump assembly.

by bending tab of lockwasher into notch of locknut.

c. Inspect the camshaft bushing type bearing for

score marks and wear patterns. Replace housing if

Fuel

Injection

Pump

3-32. Repair of

bearing is damaged or worn. Retain housing for

Housing. a. Inspect the injection pump housing

possible repair if `bearing is defective.

3-33. Repair of Miscellaneous Components. a.

pump when housing is cracked. Minor nicks or burs

may be removed with a fine mill file or crocus cloth.

General. The following paragraphs cover inspection

Check the injection pump housing against the limits

and repair of miscellaneous components. The

components covered in these paragraphs are external

specified in the repair standards (para 3-60) and

components and are not necessarily part of the

replace the pump when housing does not meet these

assemblies repaired in the preceding paragraphs.

requirements.

preceding paragraphs.

NOTE

Paragraph b applies only to code F and G

pumps.

oil filter (C). Inspect oil filter screw (A) for stripped

threads or other damage. If filter (C) or screw (A) are

damaged replace the hydraulic head assembly and

plug housing opening using kit 5704374 to plug oil

passage in pump housing.

c. Repair of Oil Hose Assembly. Refer to figure 3-

35. Inspect oil hose assembly (X) for damage,

damaged fittings, stripped threads, and

deterioration to hose structure. Replace hose

assembly if damaged. Check elbow (Y) and tee (W)

for cracks and damaged threads. Replace if

damaged.

d. Repair of Stop Plate and Bridge Assembly.

(Code G pumps only.) Refer to figure 3-12. Inspect

stop plate (F) for wear or damaged threads. Install

nut (E) and lockwasher (D) on screw of stop plate

(F). Position bridge (C) on stop plate screw with

approximately seven exposed threads between nut

(E) and stop plate. Secure with lockwasher (B) and

nut (A).

e. Repair of Plastic Lines and Fittings. There is

no repair of plastic lines and fittings, figures 3-29

through 3-33. Inspect for damage and replace lines

and fittings as required.

Figure 3-108. Location of timing pointer and tappet guide pin.

3-67

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |