|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2910-226-34

ports). As the spill passage in the fuel plunger

breaks over the top edge of the plunger sleeve,

pumping pressure is relieved and fuel delivery

terminates despite continued upward movement of

the fuel plunger.

b. When the plunger sleeve is raised, the spill

passage remains covered by the plunger sleeve until

relatively late in the plunger stroke. Hence, the

effective stroke of the fuel plunger is longer and more

fuel is delivered. When the plunger sleeve is lowered

the spill pas sage is uncovered by the plunger sleeve

relatively sooner in the plunger stroke. Hence, the

effective stroke of the fuel plunger is shorter and less

fuel is delivered.

c. When the plunger sleeve is lowered to its ex-

treme point, the spill passage is uncovered by the

top edge of the plunger sleeve before the upper end of

the fuel plunger can cover the fuel ports. Under this

condition, no pressure can be built up and no fuel can

be delivered. This is the fuel shutoff position.

1-25. Speed Governing (Typical).

NOTE

The key letters shown below in parentheses

refer to figure 1-19 except where otherwise

indicated.

a. The camshaft has two forged governor weights

(UU, fig. 1-16) attached to it through pins in a

spider. As camshaft speed increases, the weights

move out ward away from the camshaft. Fingers on

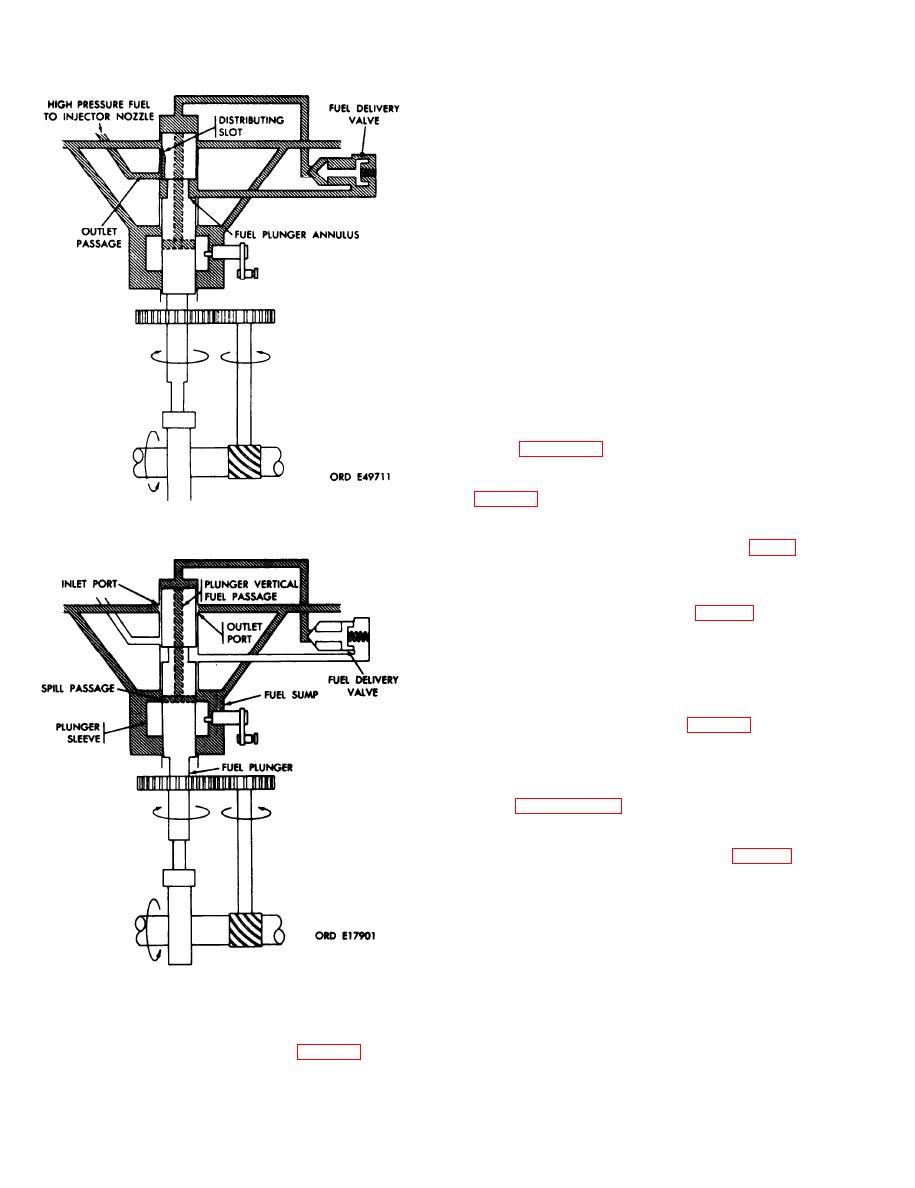

Figure 1-26. Fuel delivery flow diagram.

the weights act against the sliding sleeve (VV, fig. 1-

16).

b. The sliding sleeve is compressed against the

fingers of the governor weights by the governor

inner and outer springs (RR and SS, fig. 1-16). The

tensions of these springs balance the action of the

governor weights at any given speed within the

normal range after the sliding sleeve has shifted.

Therefore, at any given engine speed, there is a

definite corresponding sliding sleeve position.

c. The sliding sleeve is connected to the fulcrum

lever (B) through pivot pins (G, fig. 1-19). The

fulcrum lever slides in grooves in the sliding sleeve

and as the sliding sleeve moves, the fulcrum lever

moves. The fulcrum lever is also connected through

linkages to the plunger sleeve in the hydraulic head. -

As noted in paragraph 1-23 above, the position of the

plunger sleeve determines the quantity of fuel

delivered.

at its lower end on a yoke (an integral part of the

fulcrum lever) which is connected to the operating

shaft (E). The operating lever (F), which connects to

the operating shaft, is actuated through linkage

from the vehicle driver's compartment. The position

of the operating lever determines fuel delivery and

engine speed.

e. With the operating lever in a stationary

of fuel delivery flow diagram.

Figure 1-27. End

position, the lower pivot of the fulcrum lever

1-24. Fuel Metering and Control. a. The quantity of

becomes fixed. If the engine load is increased, the

engine speed will momentarily decrease and the

fuel delivered per stroke is governed by variation in

the position of the plunger sleeve (fig. 1-27) with

governor weights will lack the centrifugal force

relation to the fixed port closing position (the point

necessary to balance the spring forces on the sliding

sleeve. The fulcrum lever then shifts and moves the

at which the top of the fuel plunger covers the fuel

1-28

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |