|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

*TM 9-2815-213-34

ward position. Refer to Paragraph 3-43.

a. Install injector push rod in no. 1 cylinder. Only

no. 1 need be checked.

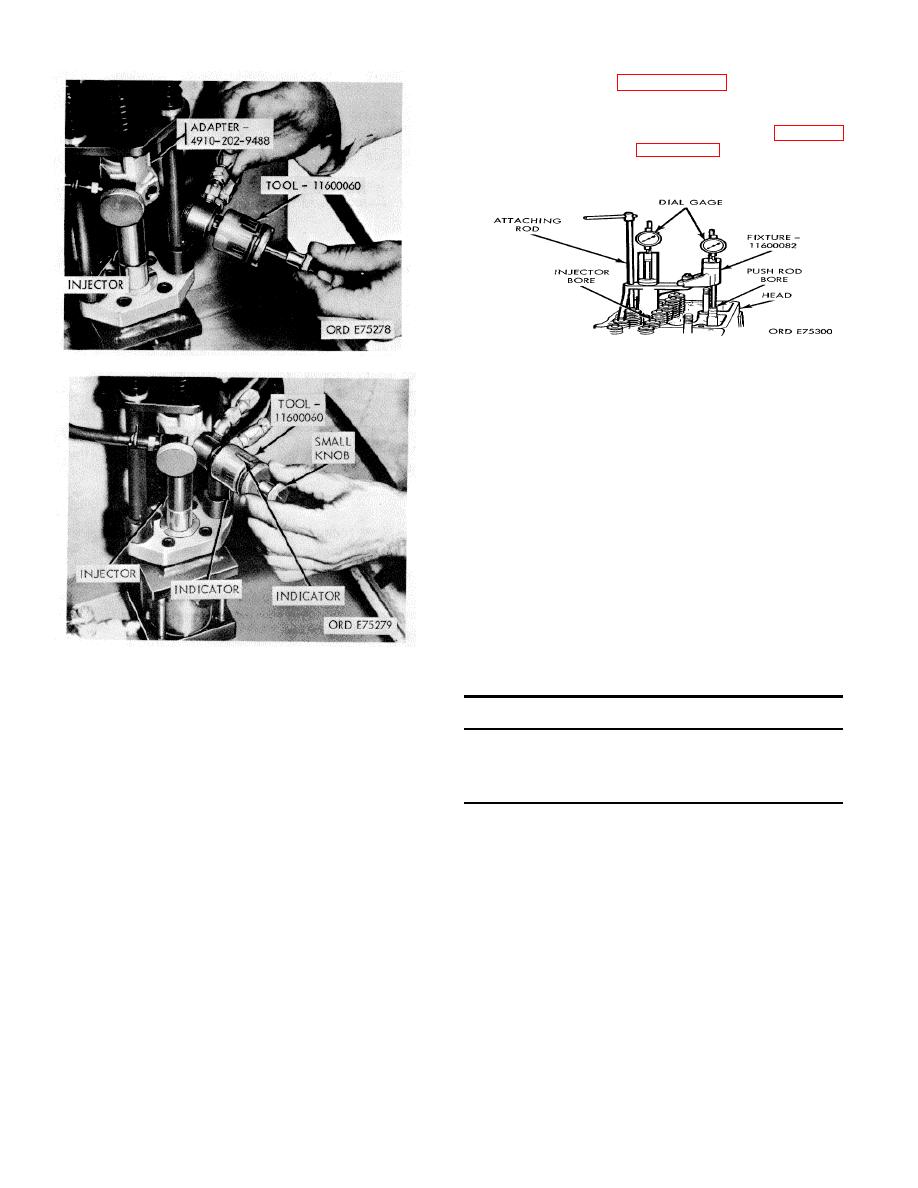

b. Install injector timing fixture (12, fig. B-28) in

injector bore as shown in figure 3-71. Indi- cator extension

must rest in socket of injector push rod. Tighten tool in place

with injector mounting capscrews.

Figure 3-71. Injector push rod timing.

Figure 3-69. Orifice hole burnishing tool installation

c. Rotate engine counterclockwise to top center

firing position. At point of maximum piston rise, set dial

indicator above piston to zero.

d. Rotate engine to 60 degrees ATDC; at this point,

60 degree mark on the moving plunger should be in line with

groove on retainer.

e. Set dial indicator for push rod travel to

zero.

f. Rotate engine in clockwise direction to ap-

proximately 60 degrees BTC of retainer. This is the same

index mark indicated in d, above.

g. Rotate engine in counterclockwise direction until

dial indicator reading shows piston has traveled to location

indicated at first check point under "Piston Travel" in chart 3-

1 below. Read push rod travel on dial indicator and check

read- ing against limits.

Figure 3-70. Orifice plug burnishing

Chart 3 -1. Injection Timing

c. Lubricate O-Rings with GAA lubricant.

Crank angle

Piston travel

Push tube travel

d. Start injectors into bores with inlet toward

degrees

inches

normal

fast

slow

camshaft. Guide them by hand until injectors are

alined in bores and not binding in any manner.

22.5 BTC

0.2032

0.0610

0.0575

0.0645

e. A hard push on injector bodies with butt

15.5 BTC

0.0816

0.0330

0.0307

0.0357

end of a hammer handle will seat injectors. A snap

6.0 ETC

0.0143

0.0135

0.0115

0.0155

should be heard and felt as cups seat in copper

sleeves.

h. Check push rod travel against piston travel

f. Install hold-down clamps, flatwashers, and

capscrews. Tighten capscrews, 30 to 35 foot-

pounds torque.

3-79. Injector Timing

NOTE

Woodruff key used to key camshaft gear to

the camshaft provides one degree advanced

timing and may be identified by a yellow-tip

which is placed in a for-

3-33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |