|

|||

|

|

|||

|

Page Title:

Section XVI. OVERHAUL OF CRANKCASE BREATHER TUBES, FIRE EXTINGUISHER TUBE, INJECTION PUMP ELECTRICAL LEAD, AND MANIFOLD HEATE... |

|

||

| ||||||||||

|

|

Section

XVI.

OVERHAUL

OF

CRANKCASE

BREATHER

TUBES,

FIRE

EXTINGUISHER

TUBE,

INJECTION

PUMP

ELECTRICAL

LEAD,

AND

MANIFOLD

HEATER

FUEL

TUBES,

FILTER

AND

ELECTRICAL

COMPONENTS

6-63. General

Specific instructions on disassembly, cleaning,

inspection, repair, and assembly accompany the

This section covers the overhaul of the crank-

case breather tubes, fire extinguisher tube, in-

overhaul operations. Refer to the following table

jection pump electrical lead, and manfiold heater

(table 6-45) for applicable illustrations

and

fuel tubes, filter, and electrical components.

instructions for overhaul operations.

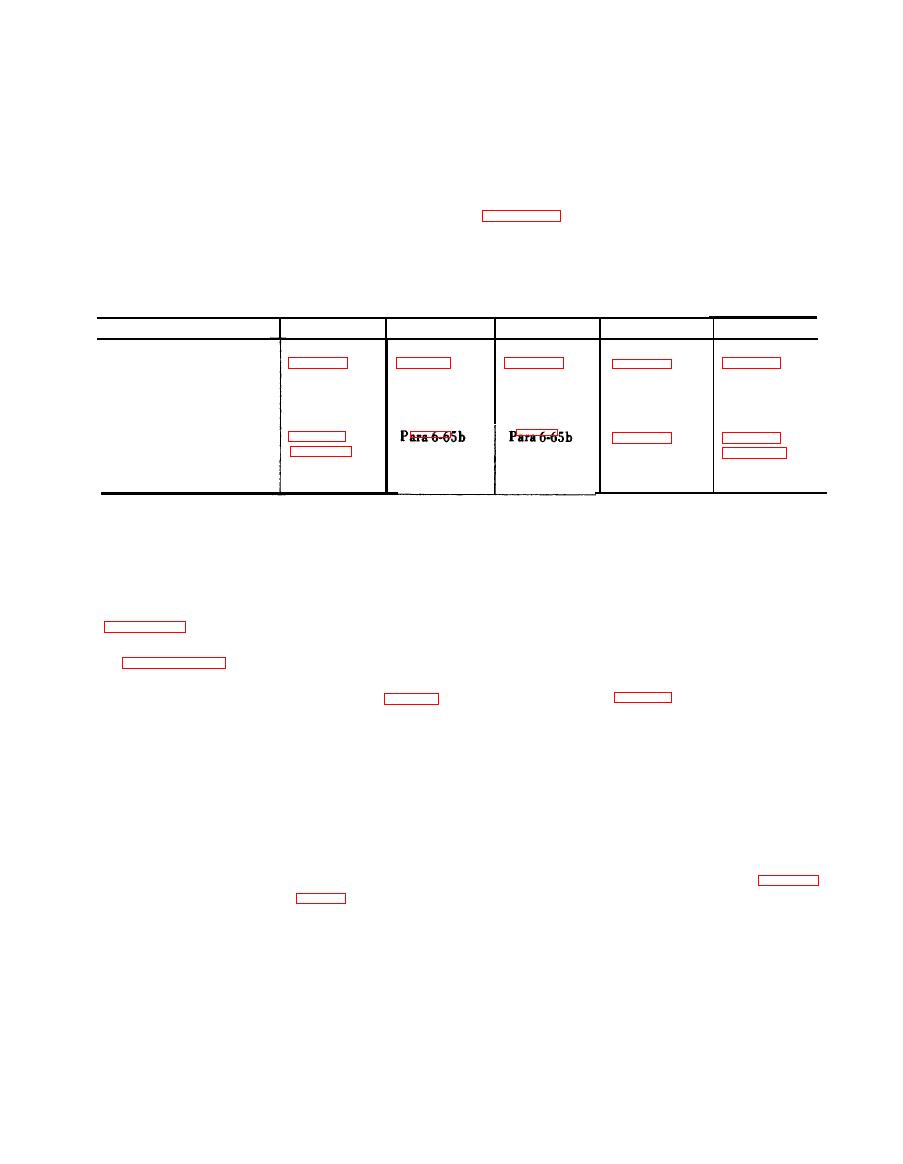

Injection Pump Electrical Lead, and Manifold Heater Fuel Tubes,

Filter, and Electrical Components

Repair

Assembly

Disassembly

Component

Cleaning

Inspection

C r a n k c a s e Breather

Tubes, Fire Ex-

tinguisher Tube,

and Pump Eletri-

cal Lead

M a n i f o l d Heater

Fuel Tubes, Fil-

ter, and Electri-

cal Components

Overhaul

of

Crankcase

Breather

bent, or dented condition. Check spray holes in

Tubes,

Fire

Extinguisher

Tube,

tube for obstructions and corrosion. Inspect tube

and

EIectrical

Lead

fittings (25 and 26) for cracks and for stripped

or

damaged

threads.

Pressure

check

tube

to

withstand

a

maximum

working

pressure

of

25

fire extinguisher tube, and electrical lead were

psi. Replace tube when cracked, badly bent, or

disassembled during engine disassembly,

when spray holes cannot be cleaned. Replace

fittings

when

cracked

or

when

threads

are

b. Cleaning, Inspection, and

Repair. R e f e r

damaged.

to paragraphs 6-2 through 6-4.

(3) Pump electrical lead. Inspect pump

(1) Breather

tubes

and

tee.

Inspect

electrical lead (51, fig. B-11) for cracked, frayed,

breather tubes (10, 11, 30, 36, and 43, fig. B-11)

and breather tube tee (16) for cracked, bent, or

or deteriorated

insulation. Inspect lead for

continuity with

a low voltage circuit tester.

dented

condition

and

for

warping

of

tube

Inspect

electrical

connectors

for

stripped

or

mounting surface. Replace when cracked or

damaged threads. Replace electrical lead when

badly dented or bent, or when mounting surfaces

insulation

is

cracked

or

broken,

connector

are badly warped. Straighten bent tubes to as

near original shape as possible. Remove minor

threads are damaged, or when low voltage tester

warpage of mounting surfaces by rubbing across

indicates

a

failure,

abrasive cloth held tightly on a surface plate or

c. Assembly. The crankcase breather tubes,

similar

flat

surface.

fire extinguisher tube, and electrical lead are

assembled

during

engine

assembly,

(2) Fire extinguisher tube. Inspect fire

extinguisher tube (24, fig. B-11) for cracked,

6-213

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |