|

|||

|

|

|||

|

Page Title:

Section V. TESTS AND ADJUSTMENTS |

|

||

| ||||||||||

|

|

c. Refer to figure 18 for instructions

covering installation of the positork

a. Refer to figures 17 through 13 for

drive assembly on the armature.

instructions covering assembly of the pin-

ion housing.

Note.

Before installing the lever

and shaft assembly, lubricate the shaft

with grease, Specification MIL-G-3278.

b. Refer to figures 12 and 11

for

instructions covering installation of the

pinion housing and brushes.

c. Measure the end play of the arma-

ture shaft using a dial indicator as shown

in figure 40. If the end play is not be-

tween 0.005 to O.O3O-inch install or re-

move fiber washers (A, fig. 13) as neces-

sary. This can be accomplished by pulling

the brushes out of their holders (fig.

assembly (fig. 21).

Replace the above

parts and recheck end play.

a. Refer to figures 8 through 5 for

instructions covering assembly of the

switch assembly.

b. Refer to figure 4 for instruction

covering installation of switch assembly

and the end cover.

Measuring armature end play.

Section V.

TESTS AND ADJUSTMENTS

35. General

Whenever a starter is tested, it should

be checked for any unusual noises or vi-

bration that might indicate an unservice-

able condition. If either condition ex-

ists, further testing should not be at-

tempted and starter returned for rebuild.

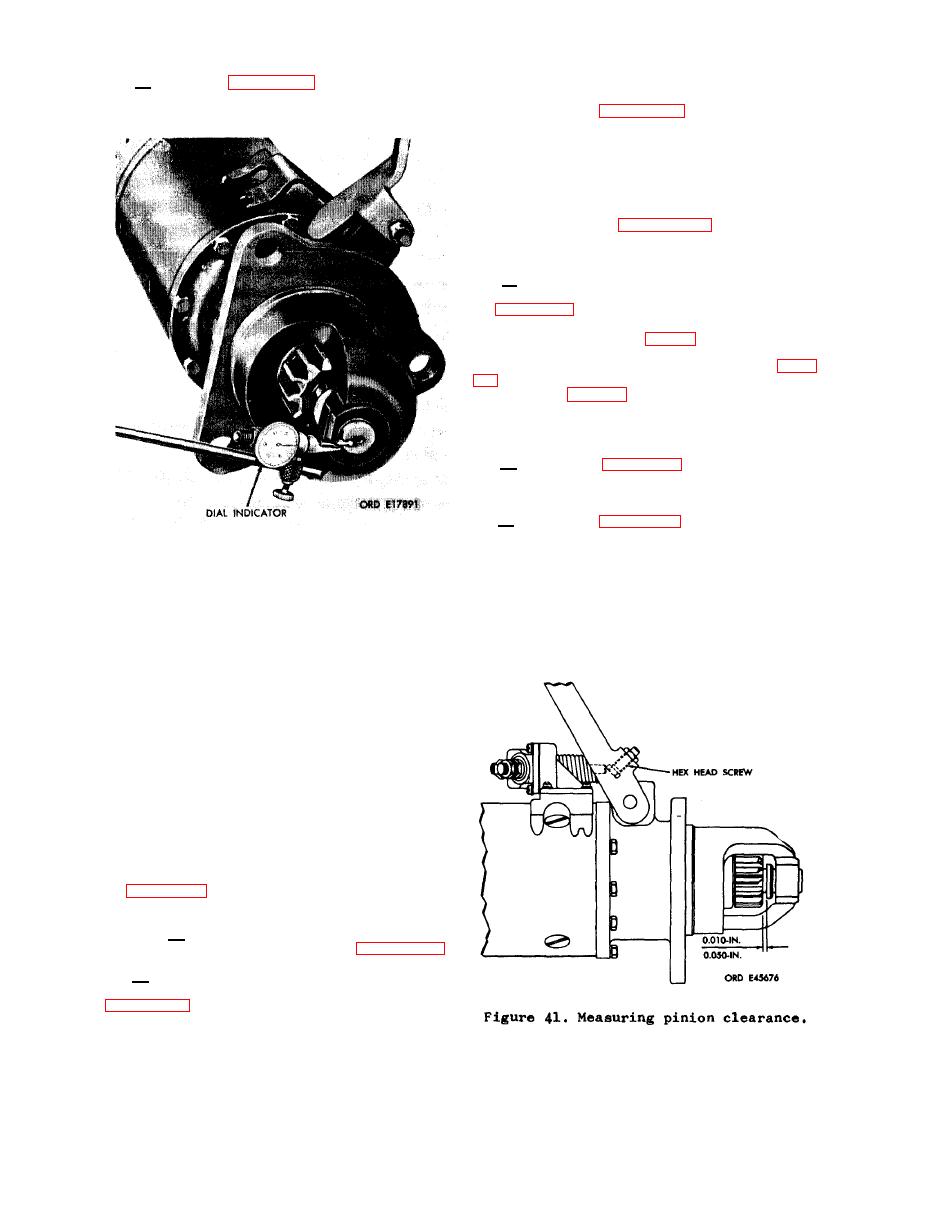

36. Pinion

Clearance

Check starter to make certain positork

drive is fully engaged when switch ener-

gizes starter motor and pinion clearance

is between 0.010 to 0.050-inch as shown

in figure 41. Perform the pinion clear-

ance check as follows:

a. Loosen locknut and turn adjusting

bolt to the position shown in figure 42.

b. Use screwdriver or wrench to engage

switch by compressing spring as shown in

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |