|

|||

|

|

|||

|

Page Title:

Installation of Tappet Assembly. |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

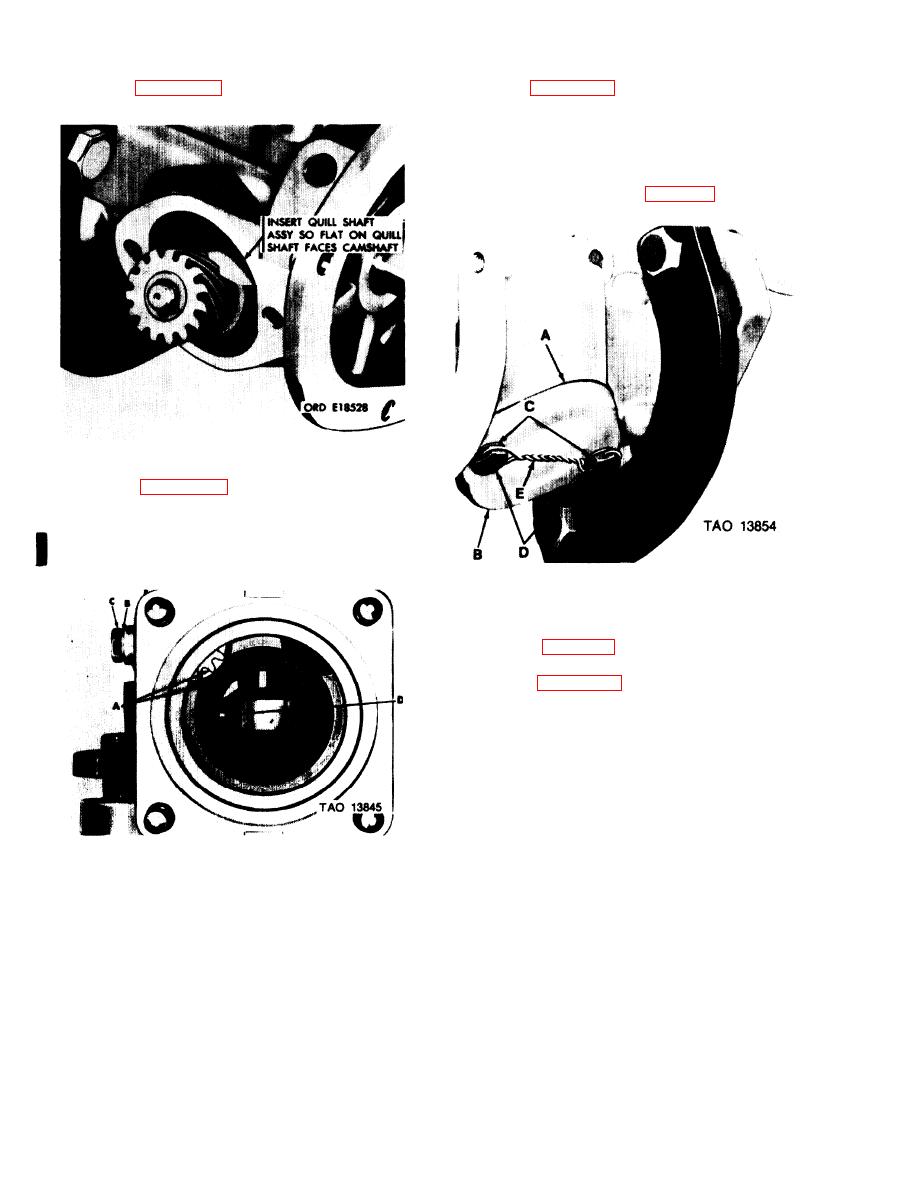

pad gasket with a thin coat of sealer, MIL-S-45180 or

equivalent. Install quill shaft pad gasket (A) and quill

shaft pad cover (B). Secure cover with two copper

gaskets (C) and machine screws (D). Torque tighten ma-

chine screws to 50-60 inch-pounds. Screws will be lock

wired at governor installation (para 3-43).

Figure 3-115. Installing quill shaft assembly.

so open tooth alines with housing mark (A), Install cop-

per gasket (B) and machine screw (C). Torque tighten

machine screw to 80-90 inch-pounds and secure with

locking wire.

Figure 3-117. Installing quill shaft pad cover.

3-39. Installation of Tappet Assembly.

a. Assembly. The tappet assembly was assembled

during repair (para 3-29).

NOTE

Refer to figure 3-118 for selection of tappet,

spring, and spring seat.

Figure 3-116. Installing quill shaft assembly in housing.

3-72

Change 2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |