|

|||

|

|

|||

|

Page Title:

Inspection of Overflow Valve Assembly |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

damage can be repaired with a used tap or die.

Replace all threaded parts that are beyond repair.

3-19. Inspection of Overflow Valve Assembly.

Inspect the overflow valve threads for damage and

inspect valve for cracks. Replace the complete

overflow valve assembly if damaged. Refer to figures

3-38, 3-39 and 3-40 for selection of replacement

Fuel Supply Pump

Fuel Injection Pump

overflow valves. Both used and new valves will be

4320-908-6322

Code A (2910 -178-1 115)

functionally inspected at pump calibration and test

4320-908-6321

Code B (2910-908-6320)

as outlined in paragraph 3-58b.

4320-908-6321

Code C, D and E (2910-759-5410)

4320-999-2276

Code F (2910-017-9778)

2910-871-5428 or

Code G (early, late and rebuild,

4320-908.6321.

(2910-860-2333 or 2910-966-6317).

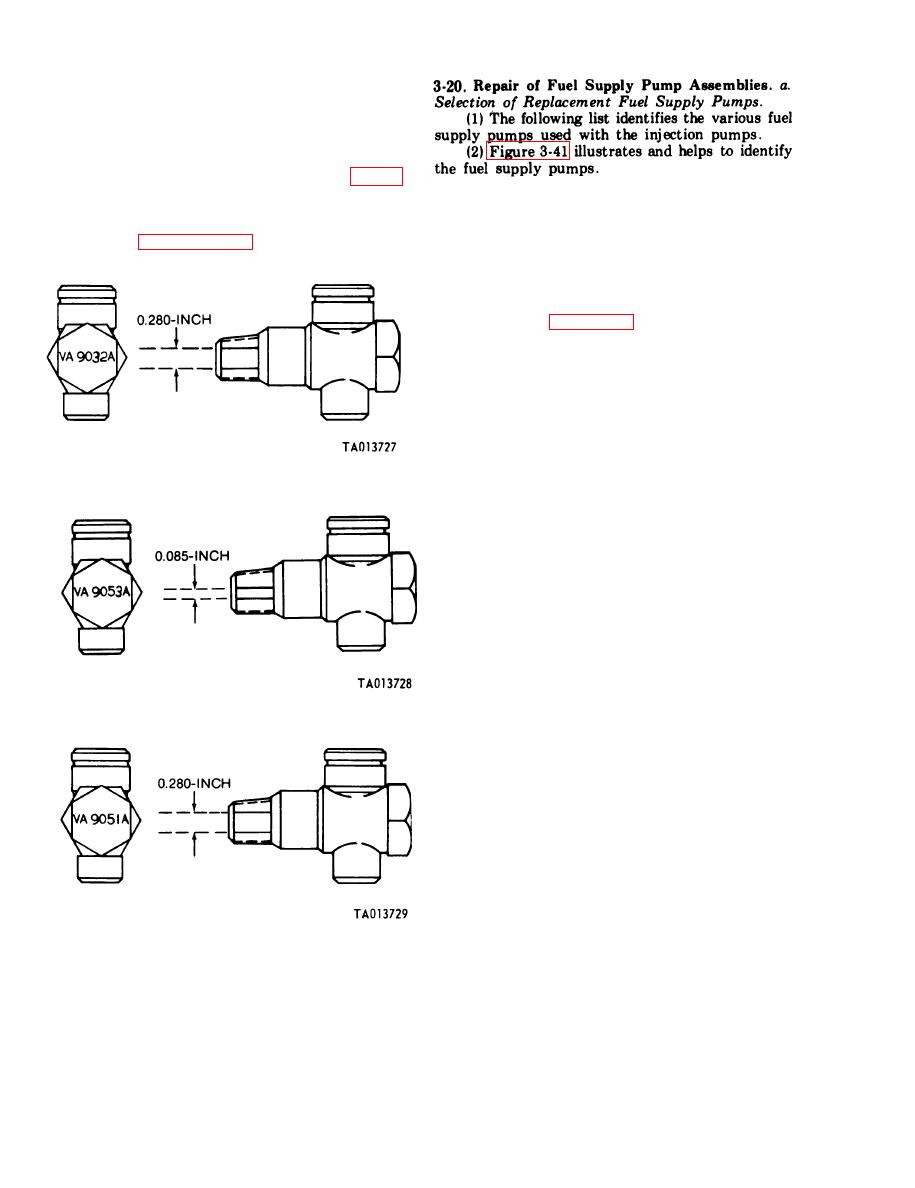

(3) Refer to figure 3-41 to distinguish the fuel

supply pump identifying features.

(a) Supply pump 4320-908-6322 has relief

valve in pump gear cover and relief valve housing is

stamped 80 PSI.

(b) Supply pump 4320-908-6321 has a flat

pump gear cover and check valve screw has -NPT

tapped hole.

(c) Supply pump 320-999-2276 has relief

Figure 3-38. Overflow valve assembly (code A. B, C, D

valve in pump gear cover and relief valve housing is

and E pumps).

stamped 60 PSI.

(d) Supply pump2910-871-5428 has a flat

pump gear cover and check valve screw does not

have tapped hole.

Figure 3-39. Overflow valve assembly (code F pump).

Figure 3-40. Overflow valve assembly (code G pump).

3-30

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |