|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2910-226-34

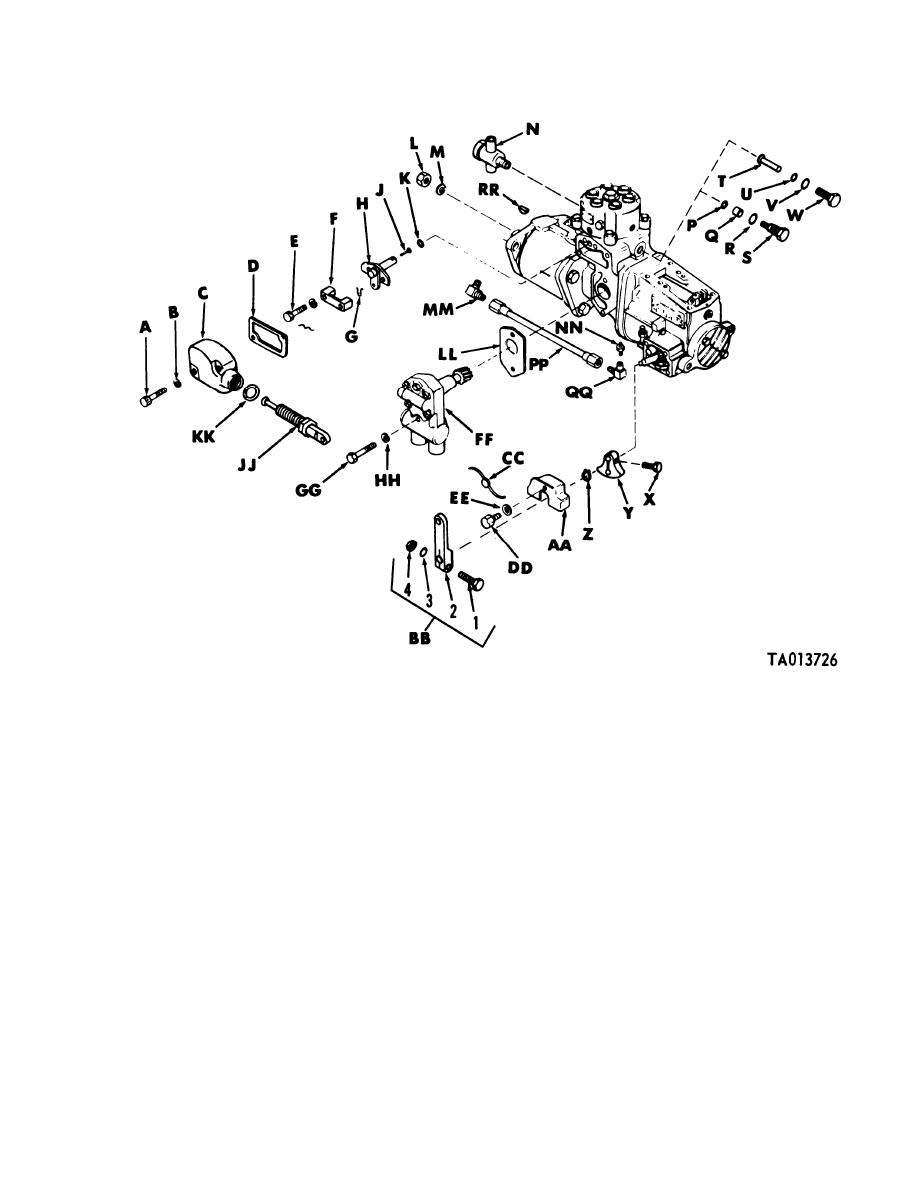

A x1 fillister head screw.

Y Operating lever stop

B -inch lockwasher

Z Retaining ring

C Timing window cover

AA Upper dust cover

D Timing window cover gasket

BB Operating lever assembly

1 Lever clamping screw

E Assembled washer screw

F Control unit retainer

2 Operating lever

G Retaining pin

3 -inch lockwasher

H Fuel control unit assembly

4 -inch nut

J Plunger sleeve pin

CC Governor lead seal

K Preformed packing

DD No. 12x3/8 machine screw

L 9/16-inch plain nut

EE No. 12 lockwasher

FF Fuel supply pump assembly

M 9/16-inch lockwasher

N Overflow valve assembly

GG x1 machine screw

P Preformed packing

HH -inch lockwasher

Q Oil filter

JJ Fuel shut-off rod assembly

R Filter screw copper gasket

KK Shutoff rod gasket

S Oil filter screw

LL Fuel supply pump gasket

T Pin

MM Pipe to tube tee

U Preformed packing

NN Pipe nipple

V Gasket

PP Oil hose assembly

W Screw

QQ 90 elbow

X Operating lever stop screw

RR Woodruff key

Figure 3-37. Code F and G injection pump assemblies, partial exploded view.

3-18. Cleaning and Inspection. a. Cleaning. Immerse

passages thoroughly. Refer to TM 9-214 for care and

and clean all parts in dry-cleaning solvent,

maintenance of antifriction bearings.

specifications PS-661, and dry with compressed air.

b. Inspection and Repair. Examine all threaded

Cover parts with a clean lint-free cloth and keep all

parts for worn or damaged threads. Minor thread

parts clean until assembly. Clean all fuel and oil

3-29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |