|

|||

|

|

|||

|

Page Title:

Table 9-2. Armature Wear Limits |

|

||

| ||||||||||

|

|

TM 9-2835-255-34

STARTER MOTOR REPAIR (Sheet 5 of 13)

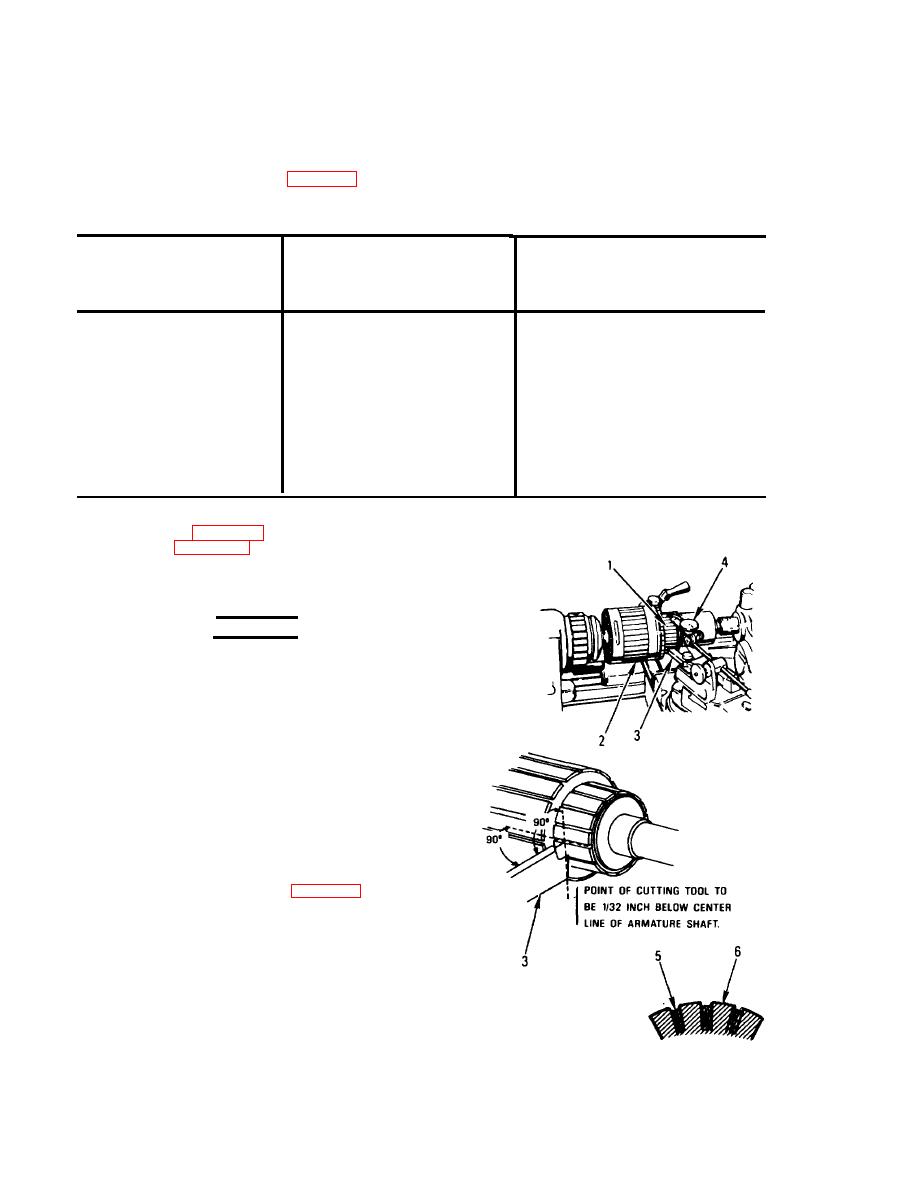

7. INSPECT COMMUTATOR (1) FOR WEAR,

a. Measure diameter of commutator (1).

Check for wear limits (table 9-2).

Table 9-2. Armature Wear Limits

Direct and GeneraI

Sizes and Fits

Point of Measurement

of New Parts

Support Wear Limits

(inches)

(inches)

Commutator Diameter

2.115 to 2.125

(5.372 cm to 5,397

cm)

Commutator Minimum

2.00

Turned Diameter

(5.08 cm)

Commutator Diameter

Total Indicator Runout

0.0020

with Shaft Diameter

(0.0508 mm)

at Bearings

b. If armature (2) is worn beyond limits

shown in table 9-2, assemble starter

motor (page 9-16) and replace,

c. Put armature (2) in lathe and position

cutting tool (3) and dial indicator (4)

against commutator (1).

WARNING

Always wear eye protection when operating a lathe.

Failure to wear eye protection could result in

serious injury.

8. CUT OFF 0.007-INCH (0.0178 MM) AND

UNDERCUT MICA (5) TO l/32-INCH

(0.794 MM) DEEP AND l/32-INCH (0.794

a, Turn lathe on. Watch indicator (4). Cut

0,005-inch (0.0127 mm) off commutator (1)

with tool (3). Turn lathe off. Check

commutator (1) for clean smooth surface.

b. Repeat step a and make final cut

0.002-inch (0.005 mm). Watch indicator (4)

to make sure total indicator runout is

within limits shown in table 9-2.

c. Turn off lathe. Pull tool (3) and indicator

(4) away from commutator (1).

d. Start grooves in mica (5) with file.

Undercut mica (5) with piece of hacksaw

blade to l/32-inch (0.794 mm) deep and

l/32-inch (0.794 mm) wide. Mica (5) must

be cut away clean between segments (6)

of commutator (1).

Go on to Sheet 6

9-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |