|

|||

|

|

|||

|

Page Title:

REMOVE REDUCTION GEARBOX LIFTING SLING |

|

||

| ||||||||||

|

|

TM 9-2835-255-34

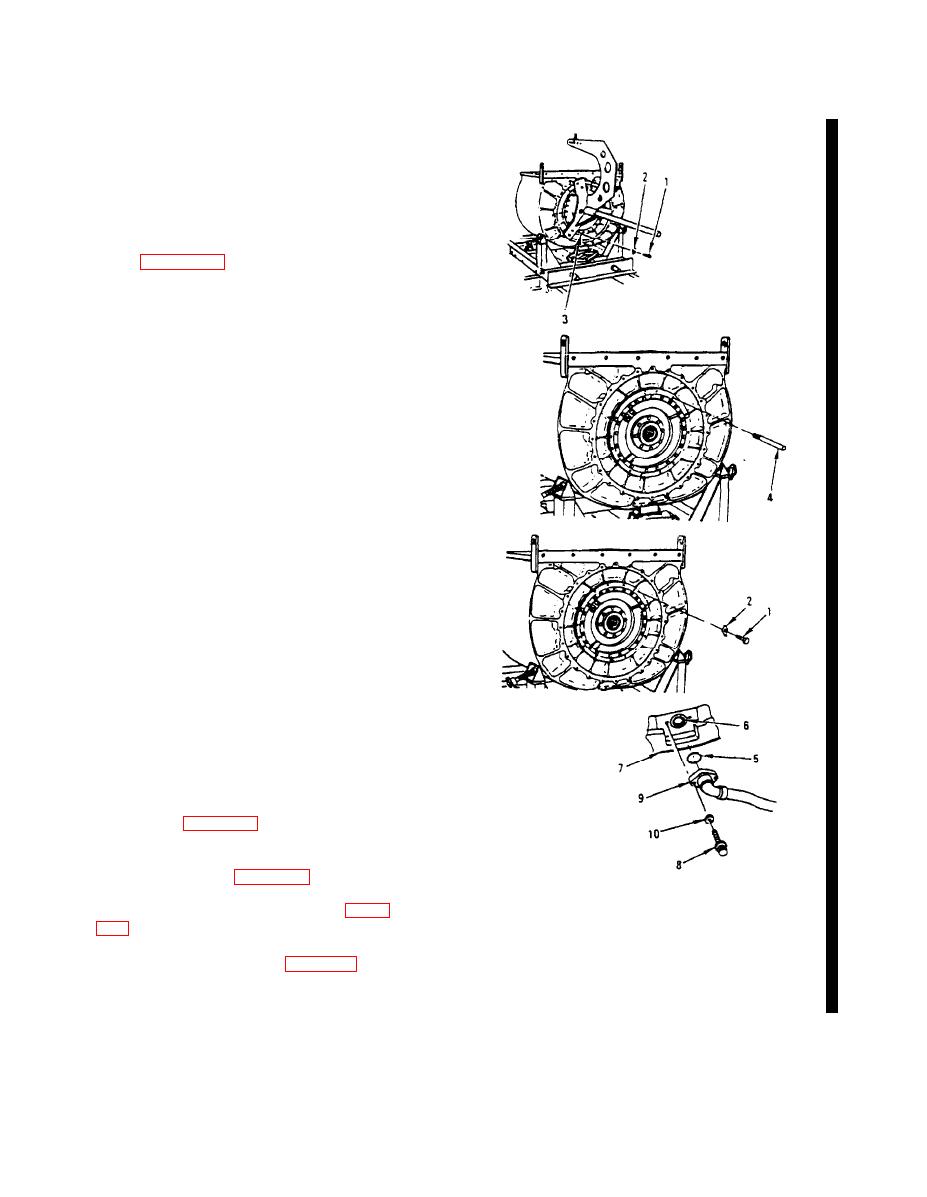

REDUCTION GEARBOX ASSEMBLY REPLACEMENT (Sheet 4 of 4)

4.

APPLY ANTISEIZE COMPOUND TO THREE

BOLTS (1). INSTALL BOLTS (1) AND NEW KEY

WASHERS (2) IN HOLES (3) AT 2,6, AND 10

O'CLOCK POSITIONS. Torque bolts (1) be

tween 210-250 Lb-In (24-28 Nm)

5.

REMOVE REDUCTION GEARBOX LIFTING

SLING (PAGE 6-16).

6.

ROTATE GEARBOX AND LISTEN FOR UNUSU-

AL NOISES. IF UNUSUAL NOISE IS NOTED, (A

RUMBLING AND KNOCKING SOUND DURING

ROTATION MAY BE AN INDICATION OF A

DAMAGED OIL DAMMING RING). REMOVE

GEAR BOX ASSEMBLY AND INSPECT THE OIL

DAMMING RING FOR VISIBLE DAMAGE

(BENT EDGES WITH SPLINE IMPRESSIONS) .

REPLACE OIL DAMMING RING AS RE-

QUIRED.

7.

REMOVE GUIDE PIN (4).

8.

APPLY ANTISEIZE COMPOUND TO 12 BOLTS

(1). INSTALL BOLTS (1) AND NEW KEYWASH-

ERS (2). TORQUE BOLTS (1) BETWEEN

210-250 LB-IN (24-28 N-M). BEND TABS OF

KEYWASHERS (2) AGAINST BOLTS (1).

9.

APPLY SHORTENING To NEW GASKET (5) AND

INSTALL GASKET (5) IN GROOVE (6) IN GEAR

BOX (7).

10. APPLY ANTISEIZE COMPOUND TO TWO BOLTS

(6). PUT. TUBE FLANGE (9) ON GEARBOX (7).

INSTALL BOLTS (8) AND NEW LOCK WASHERS

(10).

11. INSTALL TUBE ASSEMBLY (REDUCTION GEAR

BOX FEED) (PAGE 6-7)

12. INSTALL AIR TUBE ASSEMBLY (REDUCTION

GEARBOX SHORT) (PAGE 6-6).

13. INSTALL SPEEDOMETER ADAPTER (PAGE

14. INSTALL SPLINED SHAFT (PAGE 6-2).

15. INSTALL TRANSMISSION ASSEMBLY (TM

34-1).

End of Task

Change 6

6-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |