|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

*TM 9-2815-213-34

level in sight bulb with clean type A auto transmission

fluid. Be careful not to allow oil to standpipe in center

of reservoir, figure 3-59.

(4) Fill cam box with 3 inches of OE

lubricating oil. Refill with oil level drops to glass.

(5) Plug electrical connection into recel

carrying necessary voltage to operate test stand

(6) Before clamping on injector in test stand

must be timed by rotating timing wheel so

mark and pointer are alined as shown in figure

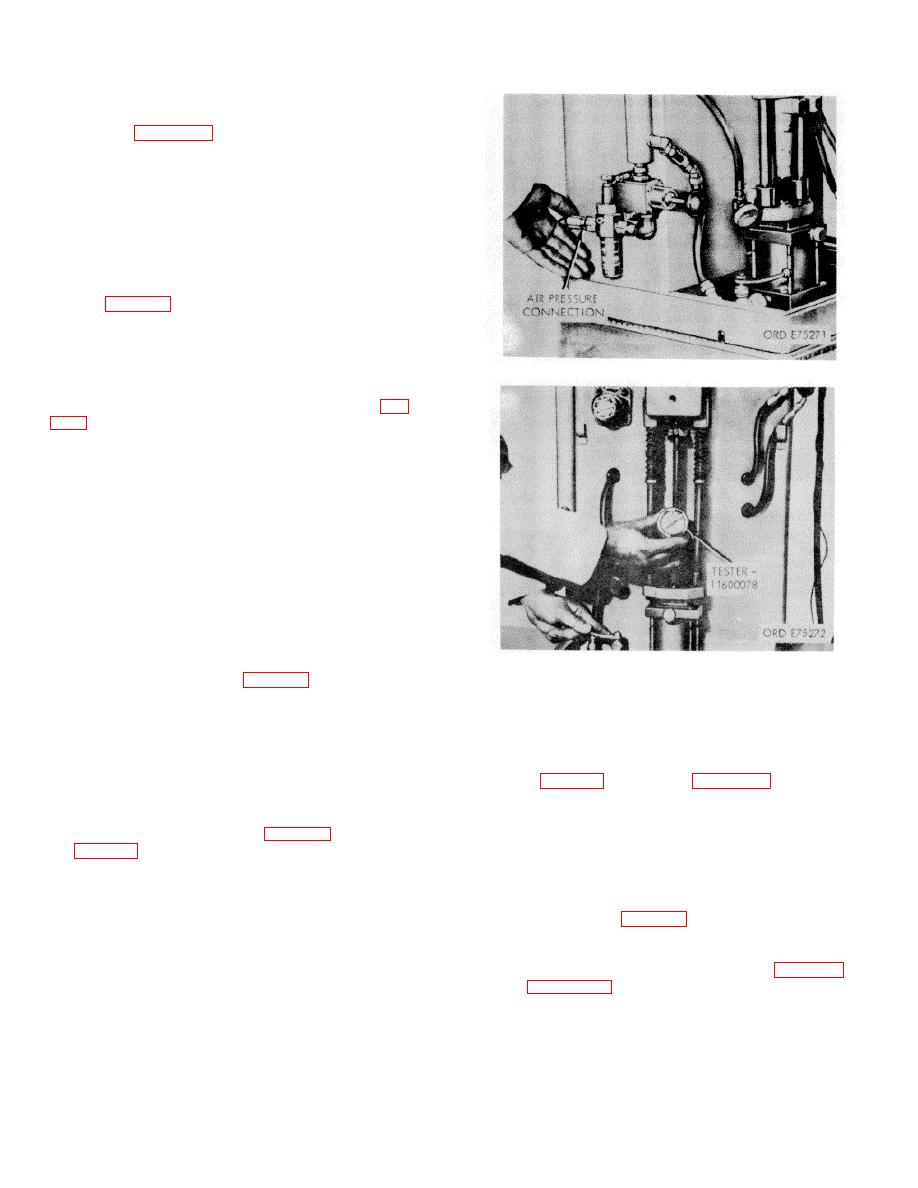

(7) Shop air pressure regulated by al

regulator is used to apply balanced force on hydl

system, (fig. 3-66). Air gage at top of hydraulic I voir

is used as a reference indicating that pre has not

changed after being set using a load tei during test

stand calibration.

Figure 3-66. Test stand air pressure connection.

(8) When air valve is opened, air travels ul in

center of tube type hydraulic reservoir and 4

downward pressure against column of hydraulic (fig.

(9) When both air valve and hydraulic valve3-

61) are opened, hydraulic fluid is admitted piston in

cylinder and lifts injector into clamped tion. Any leak

in hydraulic clamping system directly affect injector

loading and must not be per-mitted.

(10) In clamped position and with appropriate

link in place, tension on injector is same as it

operating engine. Use of improper link will clamp

load and upset delivery valves.

(11) Fuel is delivered to injector through

connector. Fuel pressure here is controlled a point

by connecting line and pressure reg (3-64).

(12) The second connection with clear plastic

Figure 3-67. Load cell tester.

line

is injector outlet connection (fig. 3-64) which c drain

3-63), assembly may be hand held. Do not place in

fuel from injector back to tank.

test stand holding device.

(13) During test stand operation, operator a

(3) Turn on test stand, and adjust pressure to 150

test cycle which diverts fuel to vial graduate so

psi.

amount of fuel being injected can be measure

(4) Check orifice plug inlet opening of injector

(14) Fuel is delivered to vial during a mea

adapter (23, fig. B-28)ras shown in figure 3-62, for

number of strokes as recorded by counter (fig. 3

leakage past ball valve.

e. Ball Valve Seating Check.

(1) Attach test stand inlet pressure line to

NOTE

connection injector adapter (23, fig. B-28) as s

Insure plunger is seated in cup.

in (fig. 3-64).

(5) If leakage is observed, the ball must be

(2) Hold injector plunger down against its

reseated.

seat in

injector cup with injector in vertical position (fig.

(1) Remove retainer plug at top of injector body.

Leave ball in place, but discard retainer gasket.

(2) Screw check ball seating tool (5, fig. B-28) as

shown in figure 3-54, down against ball and tighten to 50

inch-pounds torque.

3-31

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |