|

|||

|

|

|||

|

Page Title:

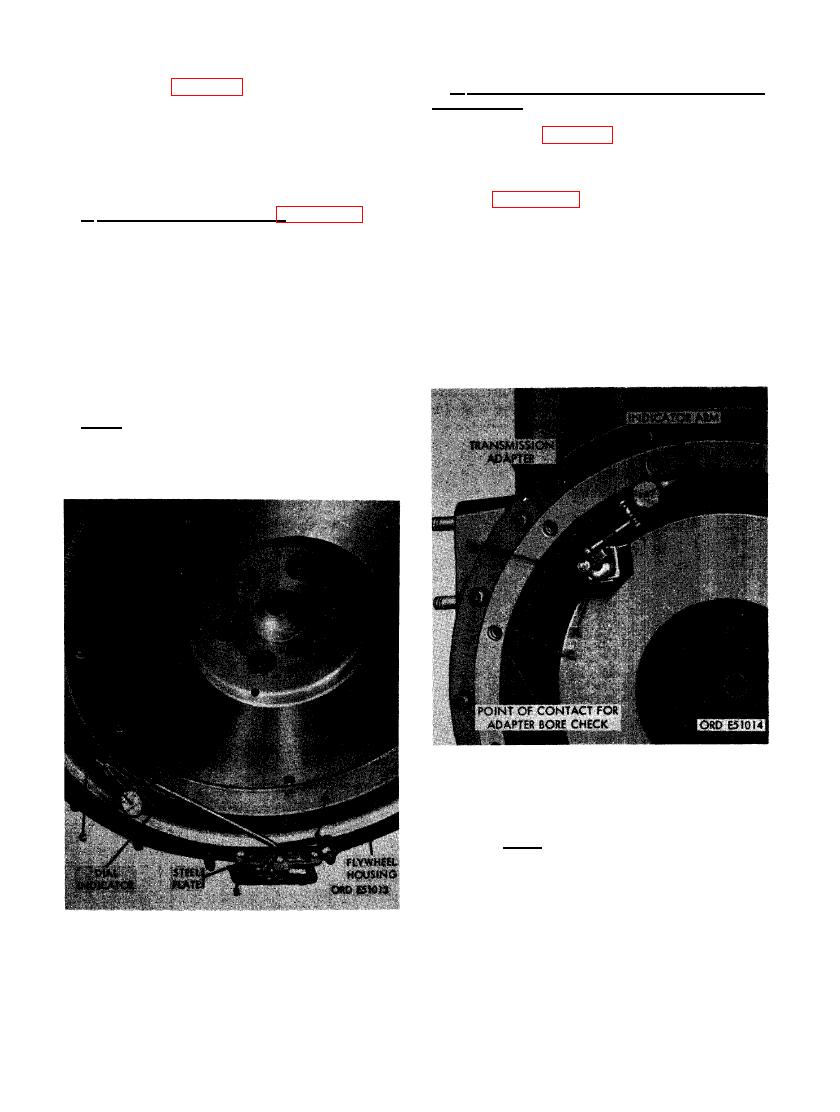

FIGURE 161. CHECKING FLYWHEEL RUN USING A DIAL INDICATOR. |

|

||

| ||||||||||

|

|

(2) Refer to figure 159 and reverse the se-

d. Install and Check Transmission Adapter

quence of instructions to install the fly-

Face Runout.

wheel. Remove pilot after flywheel is

properly positioned and all cap screw

(1) Refer to figure 158 and reverse the se-

holes aline. Tighten the six 1/2 x 1- 1/8

quence of instructions to install trans-

cap screws to a torque of 650 to 700

mission adapter.

pound inches.

(2) Figure 162. (A) Mount a magnetic base

c. Check Flywheel Runout. Figure 161. (A)

dial indicator on face of flywheel. Set

Install a small steel plate on flywheel housing

dial indicator arm against transmission

and secure to transmission adapter stud using

adapter face. (B) Turn the crankshaft

a 3/8-inch plain nut. (B) Mount magnetic base

one complete revolution and check

dial indicator on steel plate. Position indicator

adapter face runout. Exert pressure

arm against flywheel face. Dial indicator gage

against flywheel to eliminate the pos-

must contact a clean surface on the flywheel

sibility of crankshaft end play causing a

during runout check. (C) Rotate flywheel one

false reading. Maximum runout should

full revolution while pressing against crankshaft

not exceed 0 .008- inch.

to eliminate the possibility of a false reading

due to end play. Repeat the checking procedure

to insure an accurate reading.

Note. Replace flywheel if runout exceeds a

maximum of 0.008-inch.

ADAPTER FACE AND BORE RUNOUT

USING A DIAL INDICATOR.

Note. When transmission adapter face

runout exceeds 0.008-inch, check to

determine the cause of excessive run-

out. Runout can be caused by foreign

material wedged between the transmis-

sion adapter and face of flywheel hous-

ing. If no foreign material is present,

replace the adapter. (C) Check trans-

mission adapter bore in the same man-

ner except ball point on dial indicator

USING A DIAL INDICATOR.

114

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |