|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

ASSEMBLY.

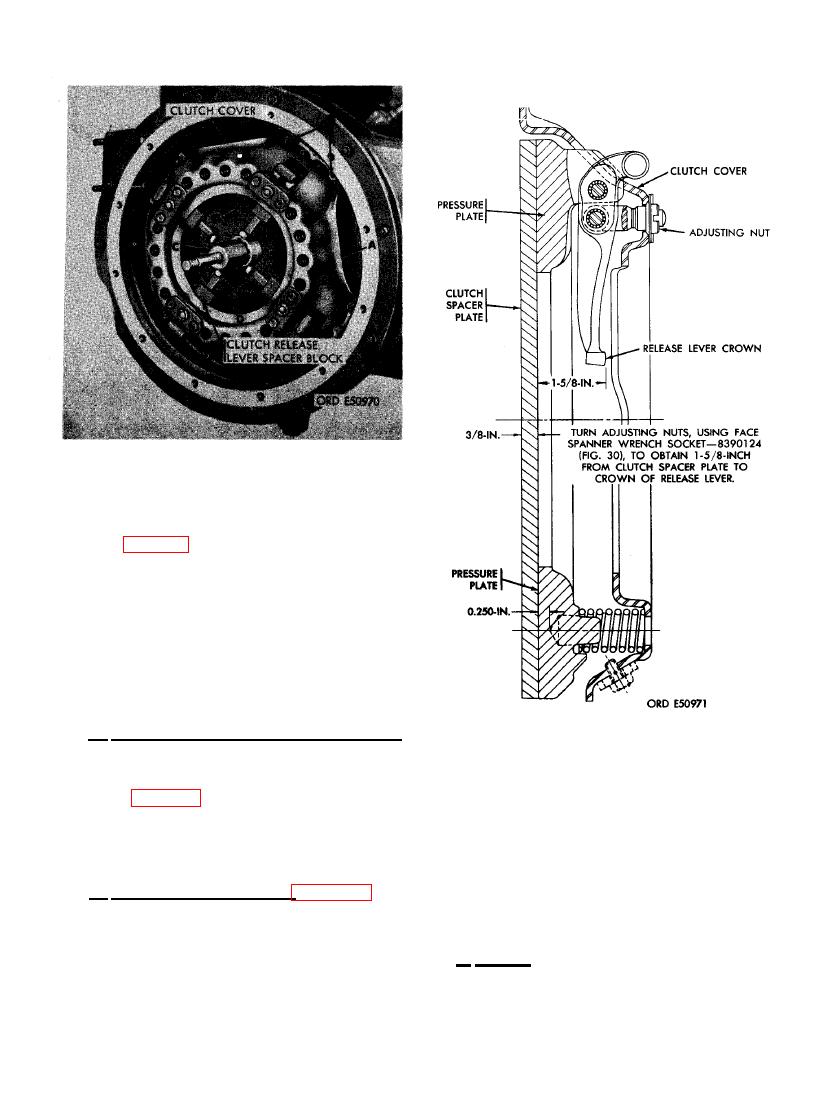

(2) Figure 97. (A) Position clutch cover as-

sembly over driven member assembly

and aline screw holes. (B) Secure cover

assembly to flywheel using eight 3/8

lock washers and 3/8 x 15/16 cap

screws. Tighten cap screws to a torque

of 275 to 325 pound inches. (C) Depress

clutch release levers, one at a time,

and remove four clutch release lever

spacer blocks. (D) Remove clutch aline-

ment tool.

d. Adjustment of Clutch Release Levers.

After clutch assembly is installed, adjust clutch

release levers to 1-5/8 inch from surface of

clutch spacer plate to release lever' crown as

shown in figure 98.

LEASE LEVER.

scratches, wear, or obstructions. Clean bore

a. Removal and Inspection. Figure 99. (A)

thoroughly using dry- cleaning solvent or mineral

Remove oil filter bypass valve plug and plain

spirits paint thinner. Remove slight burs and

washer from oil cooler and filter housing. Dis-

scratches in bore with crocus cloth.

card plain washer. (B) Remove oil filter bypass

spring and plunger from machined bore in oil

b. Repair. Repair of the oil filter bypass

cooler and filter housing. (C) Inspect oil filter

valve components is limited to replacement of

bypass valve plunger bore in housing for burs,

parts.

86

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |