|

|||

|

|

|||

|

Page Title:

Overhaul of Fuel Injection Pump Fuel Tubes, Fuel Return Hoses, and Nozzle Fuel Return Tubes |

|

||

| ||||||||||

|

|

6-60.

Overhaul of

Fuel Injection Pump

Fuel Tubes,

Fuel Return Hoses,

and Nozzle Fuel Return Tubes

a. Disassembly. The fuel injection pump fuel

tubes and nozzle return fuel return tubes were

disassembled during disassembly of engine,

b. Cleaning, Inspection, and Repair. Refer to

paragraphs 6-2 through 6-4.

(1) Fuel Injection Pump Fuel Tubes. F l u s h

the fuel tube assemblies with a high pressure

flushing

device. After flushing, blow dry with

compressed air and plug tube ends with plugs or

caps to assure cleanliness. Inspect tubes for

correct

inside

diameter

hole

dimension.

The

correct inside dimension is 0.084-inch. Tubes

with larger or smaller hole diameter are to be

discarded.

On

original

production

engines,

fuel

tubes were hand formed from straight tubes.

Carefully inspect all tubes for proper con-

figuration using a current preformed tube of like

function for comparison. Excessive bending or

hand

forming

creates

high

stress

points

and

greatly reduces tube life. Discard any tube that

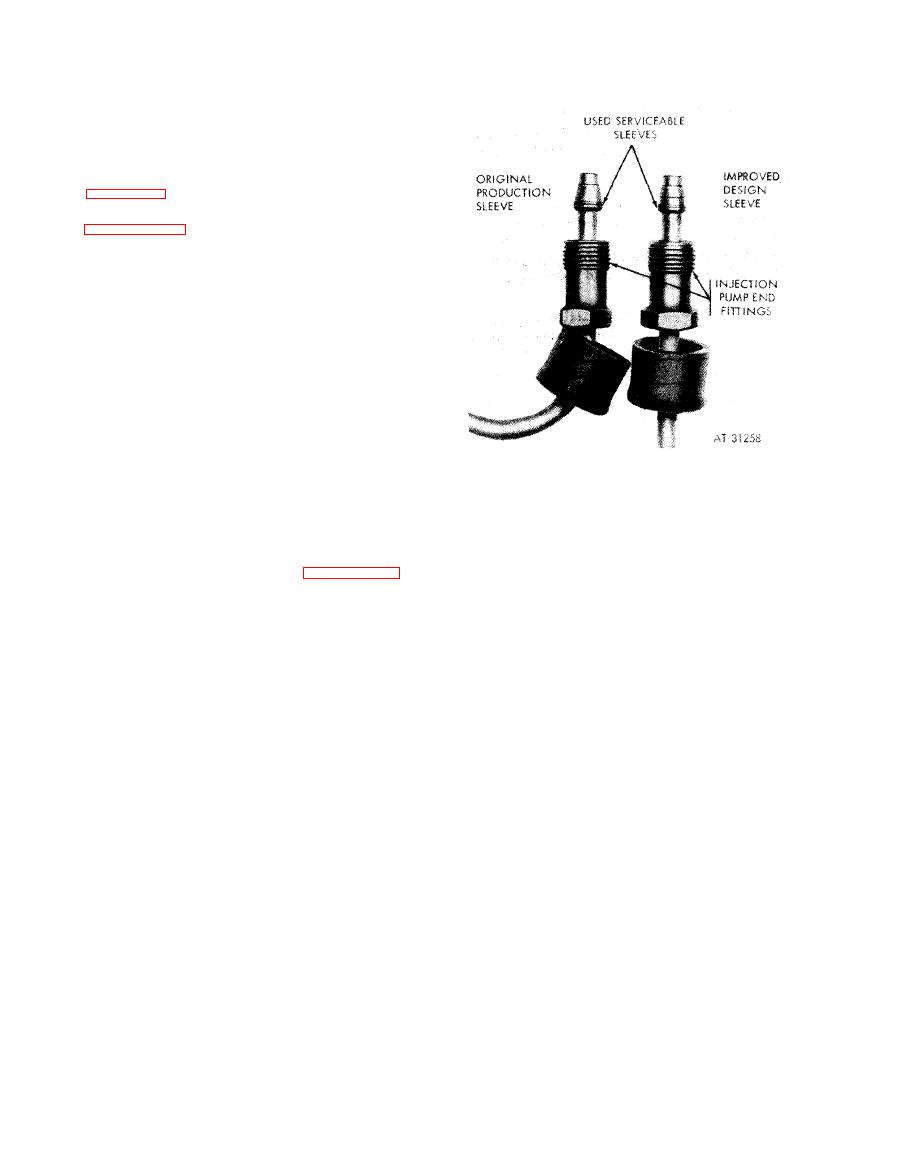

Comparison

of

serviceable

deviates from preformed comparison tube

original

production

and

improvised

Inspect tube assemblies for

configuration.

design

sleeves-fuel injection

cracks, splits or kinks and for defective safety

pump tube ends.

sleeve nut and sleeves. Refer to figures 6-248 and

6-249 for comparison of original production and

improvised design sleeve fittings shown in

serviceable and unserviceable condition.

Straighten minor bends in tubing when possible.

Discard

entire

tube

assembly

if

fittings

are

damaged or tubing has been kinked.

6-210

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |