|

|||

|

|

|||

|

Page Title:

Ultrasonic Inspection of Cylinder |

|

||

| ||||||||||

|

|

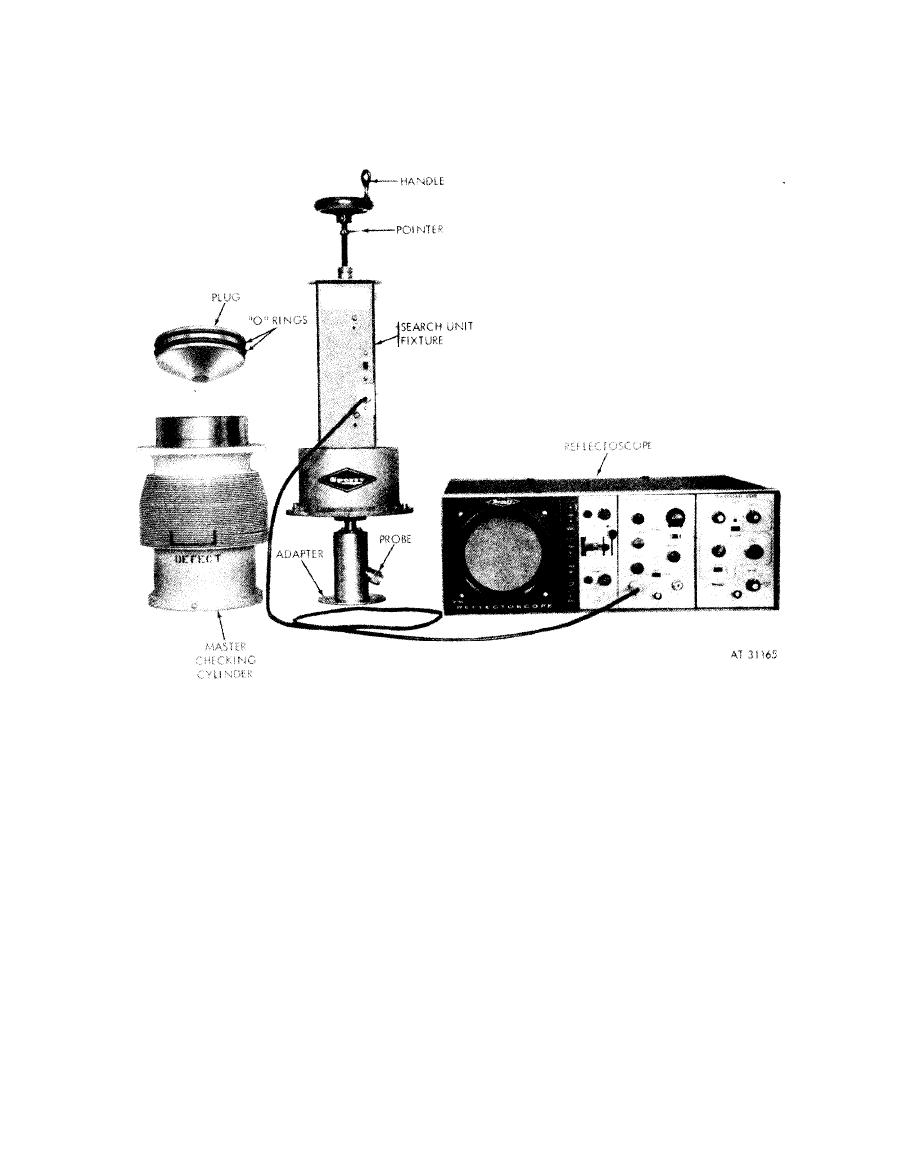

6-32. Ultrasonic Inspection of Cylinder

through e, contain the procedure for using

Barrel

(Part

No.

10865297,

FSN

cylinder barrel tester on part No. 10865297

2815-765-9711)

(2815-765-9711) cylinder only.

a. General. The following paragraphs, b

b. Description of Test Equipment.

c. Functional Description of Equipment.

(1) R e f l e c t o s c o p e . A n e l e c t r o n i c i n s t r u m e n t

(1) G e n e r a l . This inspection technique

to provide means of transmitting and receiving

utilizes ultrasonic wave propagation for a non-

pulsed ultrasonic energy, and interpretation for

d e s t r u c t i v e method of finding incipient cracks in

the cylinder. The principle of ultrasonic flaw

d e t e c t i o n of flaws in the cylinder.

d e t e c t i o n employs short bursts of high frequency

(2) Search unit fixture. An adapter that

d i r e c t s ultrasonic energy into the proper area of

sound vibrations, generated by a piezoelectric

t h e cylinder assembly, and is oriented to receive

p r o b e , transmitted into the cylinder barrel being

energy reflected back from defective areas.

i n s p e c t e d . Should a crack or discontinuity exist

(3) M a s t e r c h e c k i n g c y l i n d e r . A p o r t i o n o f

in the barrel, some of the sound wave energy will

the cylinder, properly prepared with a specific

b e reflected back to the source. A return sound

w a v e , or echo, is converted into electrical energy

d e f e c t , to act as a comparator tool. This cylinder

compares to a no-go gage relative to cracks in the

which is displayed on the screen as a vertical

cylinder.

indication on the horizontal (time) base line.

6-60

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |