|

|||

|

|

|||

|

Page Title:

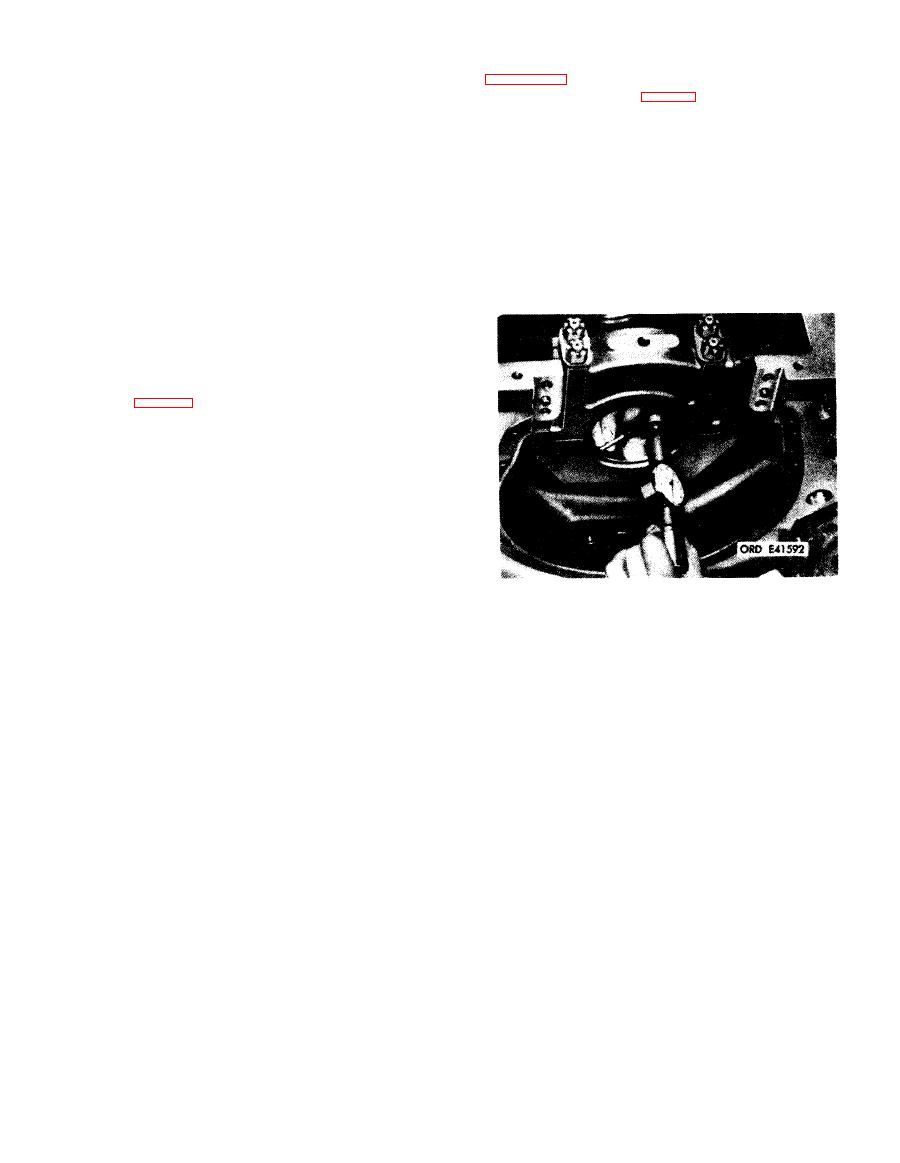

Figure 6-12. Checking inside diameter of main bearings |

|

||

| ||||||||||

|

|

figure 6-12 against the limits specified in

compound, FSN 9150-663-1770, to the

overhaul standards (table 6-2). Replace bearings

threaded area of each main bearing cap stud.

which do not meet these requirements. New

Install a plate washer on each pair of main

bearings must also be dial bore checked. Remove

bearing studs. Install a slotted nut on each main

the main bearing caps and bearing halves from

bearing stud but do not tighten nuts at this time.

the crankcase and check contact surface as

(h) Place a surface plate and dial in-

indicated by Prussian blue, FSN 8010-847-

dicator gage on crankcase flange with gage

8706 transfer. Replace bearings that do not

indicator resting on end of stud. Measure and

record height of each stud. Torque tighten main

make 75 percent contact with crankcase bearing

bores. Repeat dial bore check of new bearings

bearing stud nuts to 500 pound-inches. Alter-

installed.

nately tighten all four nuts on each main bearing

to a torque of 700-825 pound-inches. Measure

the height of each stud after final torque. The

difference between the stud height before and

after torque tightening, indicates stud stretch.

Normal stud stretch is 0.010 to 0.022-in. If any

stud has stretched more than 0.024-in. at 700

pound-inches torque, it must be replaced. Refer

to

6-3

when

replacing

studs.

(i) Install the 14 crankcase tie rods in the

holes provided through the crankcase and main

bearing caps. Equalize the extension of the

threaded portions of the tie rods on each side of

the crankcase. Apply a small amount of antiseize

compound, FSN 9150-663-1770, to the

threaded portions of each tie rod. Install a plate

washer and a 9 / 16 slotted nut on each end of

the tie rods.

(j) Starting at the main thrust bearing

cap, with aid of an assistant to hold the nuts on

the opposite s i d e o f c r a n k c a s e , alternately

tighten all main bearing cap tie rod nuts to 640

Figure 6-12. Checking

inside

diameter

of

pound-inches torque.

main

bearings.

(k) Check the inside diameter of the main

bearings with a dial bore indicator as shown in

6-17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |