|

|||

|

|

|||

|

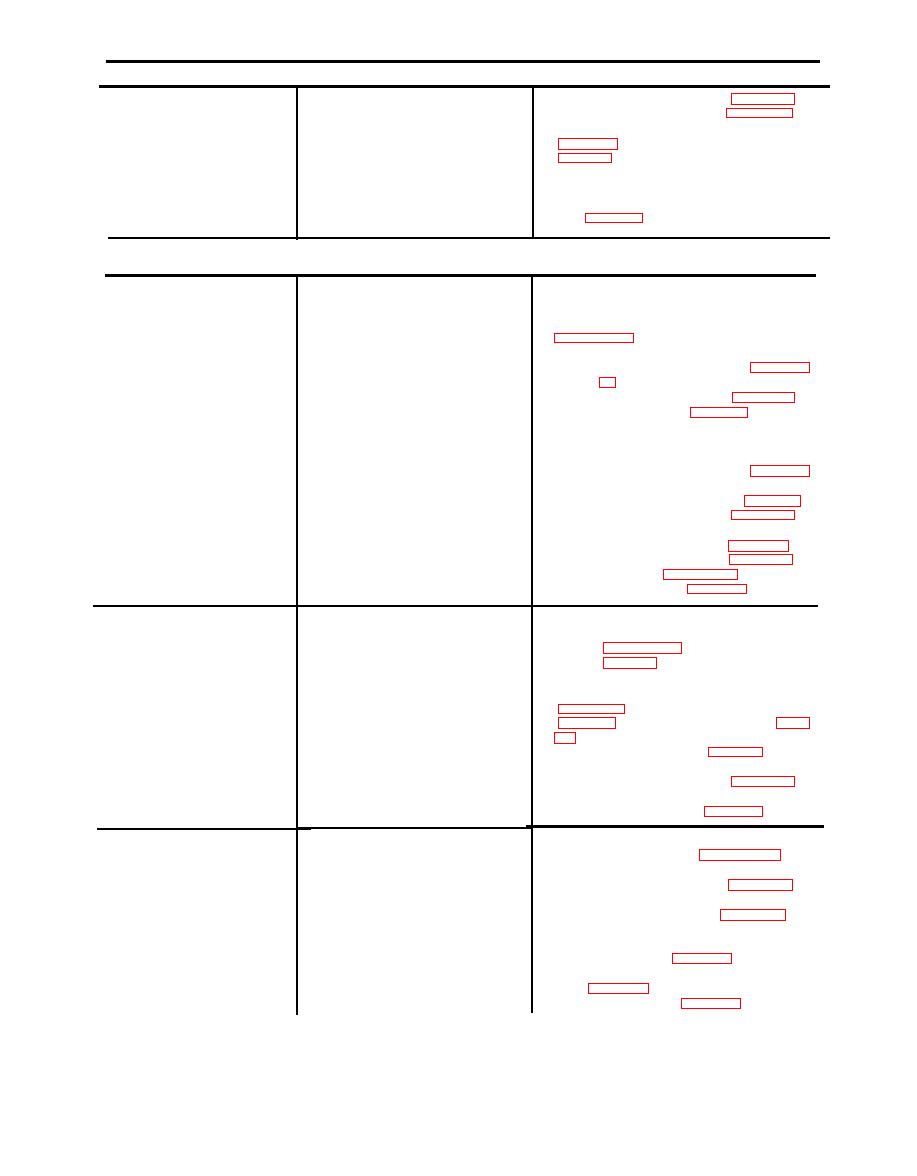

Page Title:

Troubleshooting Fuel System |

|

||

| ||||||||||

|

|

Corrective Action

Probable Cause

Malfunction

2. Loss of engine power.

a. Air leak in intake manifold.

a . Remove turbosuperchargers (table 4-1).

Remove intake manifolds (table 4-4).

R e p a i r air leak. Install intake manifolds

b. Refer to 1c, above for corrective action.

b. Turbosuperchargers worn,

plugged, or failed.

c. Repair or replace exhaust pipes and mani-

c. Leak in exhaust pipes or

folds (table 5-5).

a. Service primary fuel filter, secondary fuel

a. Plugged primary fuel filter,

1. No fuel being delivered

filter, or fuel/water separator filter. Refer

secondary

fuel

filter, or

from fuel injector nozzles.

t o pertinent vehicle Technical Manual,

fuel/water separator filter or fuel

system not free of air.

b. Troubleshoot vehicle fuel system. Refer to

b. Defect in vehicle fuel system.

p e r t i n e n t vehicle Technical Manual, Ap-

pendix A for procedures.

c. Remove damaged fuel hoses (table 4-1).

c. Damaged fuel hoses (fuel pump to

Install new fuel hoses (table 4-1).

f i l t e r or filter to fuel injection

pump).

d. Troubleshoot fuel pump. Refer to TM 9-

d. Defective fuel pump

2 9 1 0 - 2 1 3 - 3 4 for procedures. If trouble

cannot be corrected remove pump (table 4-

1). Refer to TM 9-2910-213-34 for

overhaul. Install pump (table 4-1).

e. Remove fuel injection pump (table 4-1).

a. Failed fuel injection pump.

Refer to TM 9-2910-212-34 and overhaul

pump. Install injection pump (table 4-1).

f. Remove fuel injection pump (table 4-1).

f. Failed fuel injection pump

R e p l a c e coupling (tables 6-29 or 6-45).

coupling.

Install injection pump (table 4-1).

a. Operating with contaminated fuel

a. Drain fuel tank and refill with proper fuel.

2. Fuel being delivered at

or partially plugged fuel filters,

nozzles but engine will not

Refer to pertinent vehicle Technical

refer to 1a, above.

stare run, or runs rough on

Manual, Appendix A, for proper fuel.

one or more cylinders.

b. Flame heater not operating (low

b. Refer to para 3-4 (2 and 3) for corrective

ambient temperature).

action.

c. Fuel injector nozzle and holder not

c. Remove fuel injector nozzle and holders

functioning properly.

4-7 ).

d . Fuel injection pump not timed

d. Time fuel injection pump (para 4-4). Also

properly.

refer to TM 9-2910-212-34.

e . Fuel injection pump not func-

e. Remove fuel injection pump (table 4-1).

tioning properly.

Refer to TM 9-2910-212-34 for overhaul

procedures. Install pump (table 4-1).

3. Engine runs hot, misfires, or

a. Restricted induction air supply.

a. Service air cleaner. Refer to pertinent veh-

runs rough.

i c l e Technical Manual, Appendix A, for

proper fuel.

b. Low fuel pressure from fuel supply

b. R e m o v e fuel supply pump (table 4-1).

pump or leaking hoses and con-

Refer to TM 9-2910-213-34 for overhaul

nections.

p r o c e d u r e s . Install pump (para 7-17a).

Tighten all connections and replace

damaged hoses.

c . Remove engine fan (table 4-3).

c. Fan clutch slipping.

d. Leaking fuel tubes at nozzle and

d. Tighten connections. Remove fuel injector

holder assemblies.

tubes (table 4-1). Replace damaged tubes.

Install injector tubes (table 4-1).

3-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |