|

|||

|

|

|||

|

Page Title:

Section VI. REPAIR (MODEL T-136-21) |

|

||

| ||||||||||

|

|

TM 9-2520-246-34

Section VI. REPAIR (MODEL T-136-21)

4-21. General.

a. This section contains disassembly and assembly

procedures for the model T-136-21 transfer.

b. Clean, inspect, and follow the repair procedures

in Chapter 2, section III, of this manual.

c. Transfer disassembly is accomplished by the

logical step-by-step procedures in paragraphs 4-22 and

4-23. Refer to paragraphs 4-24 and 4-25 for assembly

procedures.

NOTE

Assembly procedures are given only where

special attention to a part or assembly is

needed. Assembly of the transfer is the

exact opposite of disassembly, unless

otherwise specified or stated.

4-22. Disassembly of Transfer into

Subassemblies.

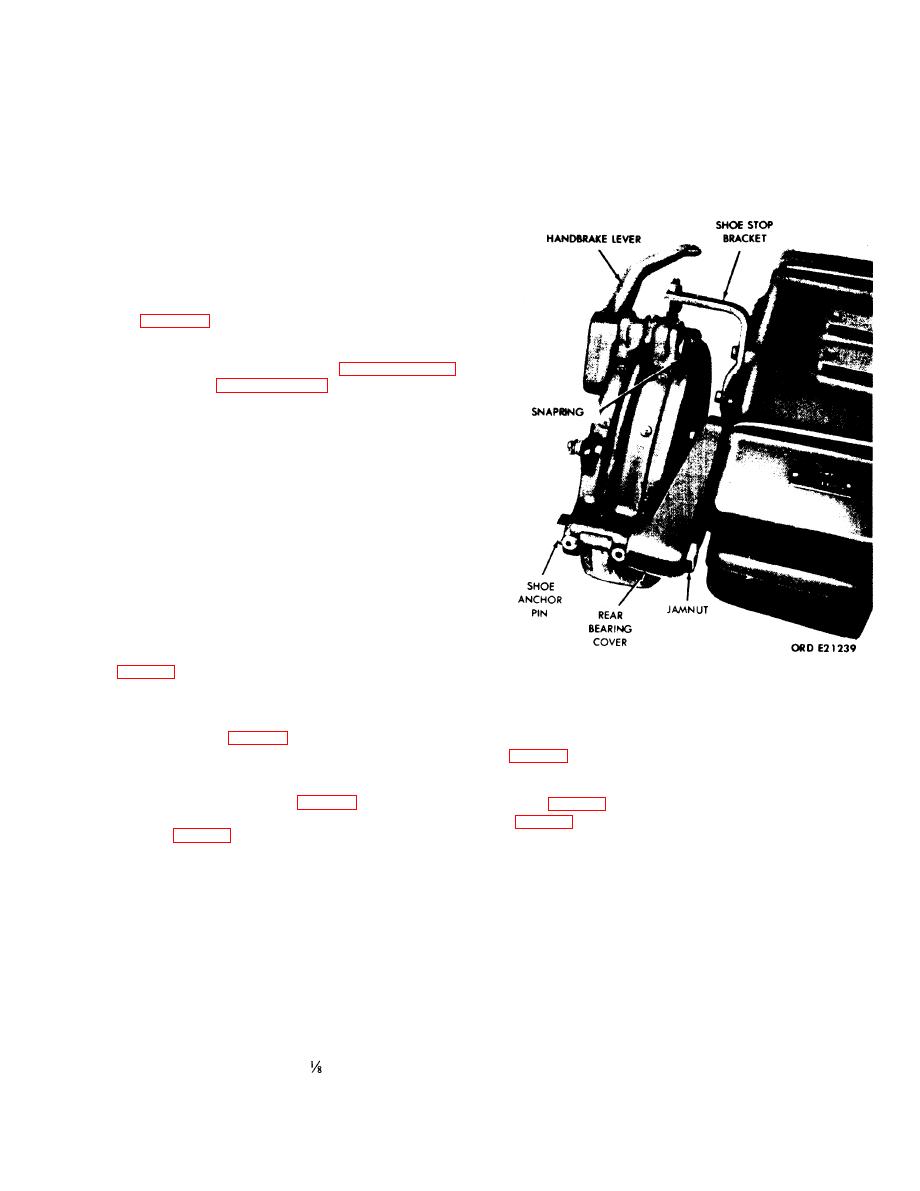

a. Handbrake Drum and Shoe Assembly. Remove

the cotter pin from the rear output shaft and nut. (See

Figure 4-28. Removal of Handbrake Assembly.

the rear output shaft companion flange, nut, and

washer. Disconnect and remove the handbrake shoe

return spring. Remove the jamnut from the shoe

b. Installation of Transfer on Overhaul Stand.

anchor pin. (See fig. 4-28.) Unscrew the anchor pin

Install transfer on overhaul stand using brackets. (See

from the rear-output-shaft rear-bearing cover. Slide

the brakeshoe assembly from the brakedrum. Pull the

companion flange, brake drum, and grease shield from

c. Draining. Remove transfer case magnetic drain

the rear output shaft. (See fig. 4-27.) Remove the two

plug (fig. 4-27) and front output shaft cover filler plug

capscrews and lockwashers securing the shoe-stop

bracket (fig. 4-28) to the transfer case and remove the

container. Inspect magnetic plugs for chips.

bracket.

NOTE

NOTE

If chips are found, inspect in accordance

with repair and replacement standards.

Apply white lead pigment (Fed Spec TT-

(Refer to section VIII.)

W-261C) to the spline of the rear output

d. Companion Flanges.

shaft before installing handbrake drum and

rear output shaft companion flange.

NOTE

Tighten nut to 300-400 lb-ft torque. Place

washers on anchor pin to space brake shoe

so that 1/16 inch of drum shows. Tighten

Apply a coating of white lead pigment, Fed

pin until binding occurs when brake is

Spec TT-W-261C, to input shaft spline

applied and back off

turn. Tighten

before installing companion flange. Tighten

locknut to 153-196 lb-ft torque.

flange nut to 300-400 lb-ft torque.

4-21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |