|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

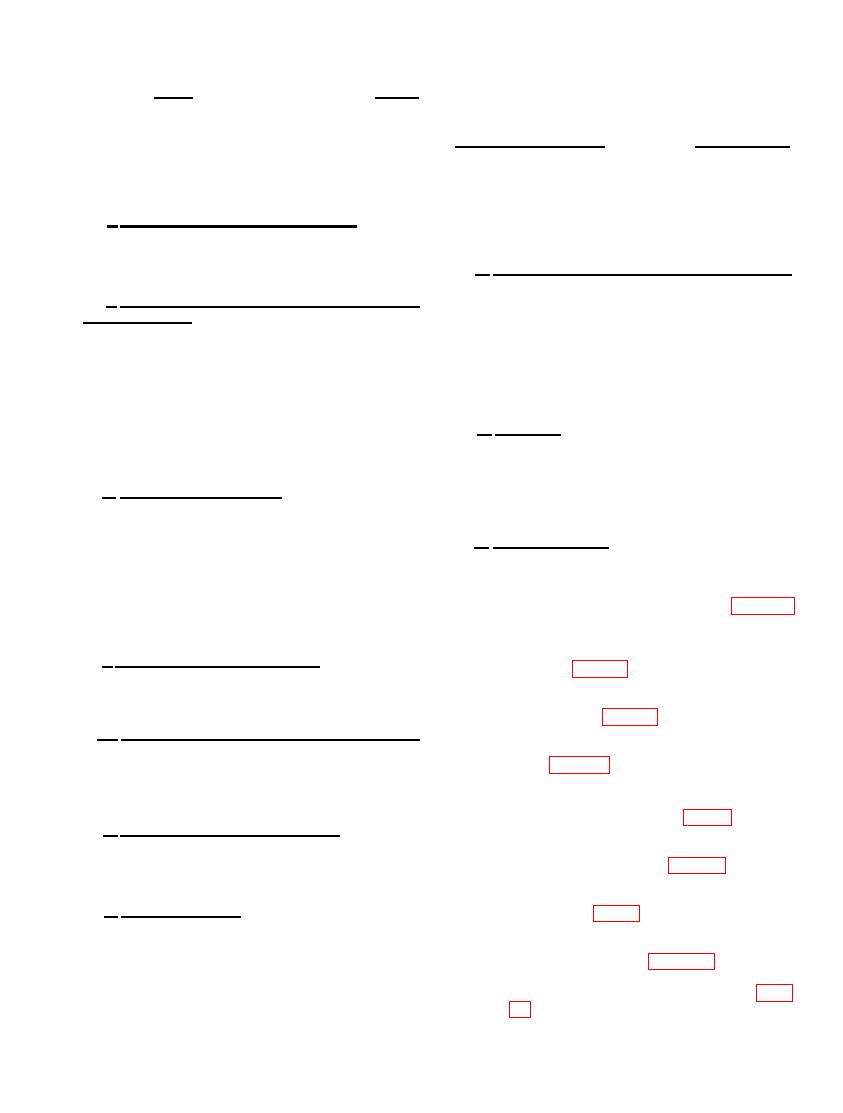

Fuels

lbs/hr

Smoke Density Chart

(Robert Bosch Model EFAW-68 Meter)

Diesel Fuel (W-F-800)

61

56

Exhaust Smoke Color

Classification

Compression Ignition Fuel

(MIL-F-46005)

No.

1

Gasoline (MIL-G-3056)

Clear

50

No.

2

Haze

Light Gray

No.

3

Medium Gray

No.

4

i. Fuel Pressure and Temperature. The fuel

pressure at the fuel injection pump inlet shall

No.

5

Dark Gray or Black

be 50 to 60 psi at 2600 rpm. Fuel temperature

shall be maintained at 80 F 5 F.

p. Fuel Injection Pump Governor Setting.

The governor shall maintain engine rpm be-

tween 2600 and 2650 rpm at full load; 2850

j. Coolant Specifications (also refer to TM

rpm maximum at no load. The engine speed

9-2-20-235-10).

shall stabilize within 3 seconds after full

(1) O-A-548 Antifreeze Ethylene Glycol,

throttle position is reached. Seal governor

Inhibited.

adjustment.

(2) MIL-C-11755 Compound, Antifreeze,

Arctic Type.

a. General. The engine must be pressure

(3) 0-1-490 Inhibitor Corrosion, Liquid

tested to determine whether or not all con-

nections are watertight and airtight. The in-

Cooling System.

structions below describe a method that can

k. Coolant Temperature. Coolant Tempera-

be used without submerging the engine in

ture shall be maintained at 180 to 200 F through-

water.

out the speed range. Coolant temperature rise

through the engine shall not exceed 10 F from

b. Seal Openings. Seal all openings as di-

inlet to outlet when the engine, with thermostat

rected in (1) through (9) below.

fully open, is operating at full throttle and

2600 rpm. Coolant temperature shall never

(1) Tape exhaust outlet opening on turbo-

exceed 220 F with a 4 psi pressure in the

supercharger exhaust elbow (figs. 46

external cooling System.

and 47).

(2) Tape air inlet opening at turbosuper-

l. Induction Air Temperature. Induction air

charger (figs. 53 and 54).

temperature, before turbosupercharger, shall

be 70 to 90 F.

(3) Tape water outlet opening on thermo-

stat housing (fig. 109).

m. Turbosupercharger Manifold Pressure.

(4) Tape water inlet opening on water

The turbosupercharger shall develop a minimum

pump (fig. 116).

intake manifold pressure of 47- inches of mer-

cury absolute when operating a full load at

2600 rpm using Diesel fuel (VV-F-800).

(5) Tape air compressor air intake mani-

fold and outlet openings (fig. 85).

n. Intake Manifold Flame Heater. The intake

manifold flame heater shall ignite and function

(6) Tape fuel inlet fitting on fuel injection

properly when a minimum of 10 volts is ap-

pump fuel supply pump (figs. 21 and 22).

plied across the terminals.

(7) Tape fuel return tee opening in fuel

o. Smoke Density. The maximum smoke

filter head (fig. 21).

density at full throttle at speeds above 1400

rpm through the remaining speed range, mea-

(8) Tape 1/8- inch pipe tap opening (upper)

sured within 3 feet of the turbosupercharger

in breather tube (figs. 44 and 45).

outlet, shall not exceed a No. 3 smoke condi-

tion (light gray) when using any of the approved

(9) Tape open end of breather tube (figs.

fuels.

327

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |