|

|||

|

|

|||

|

Page Title:

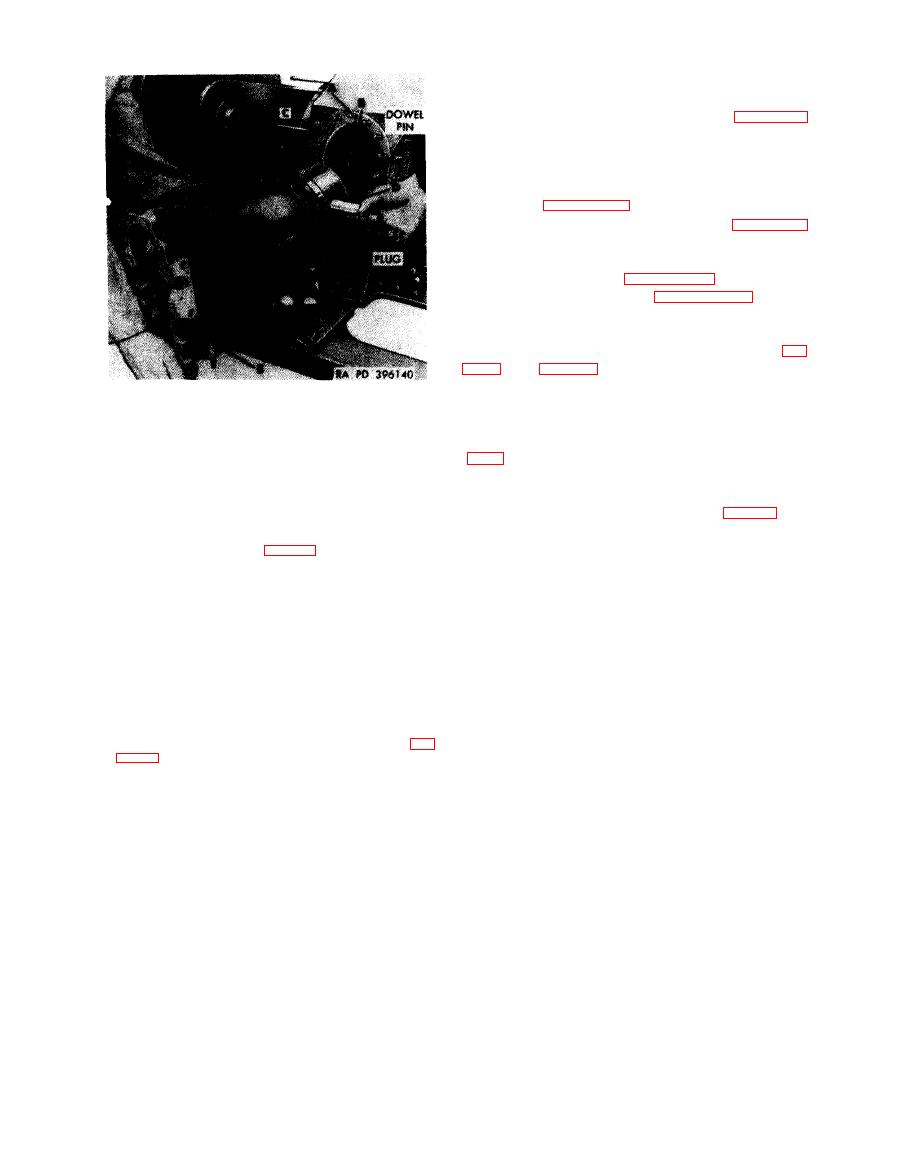

Figure 7-13. Installing cylinder assemblies on Crankcase |

|

||

| ||||||||||

|

|

(c) When all cylinder assemblies are

installed as described and illustrated in figure 7-

13, install remaining cylinder extended washer

nuts and torque tighten the nuts alternately to

640 pound-inches. Use box wrench - 5120-678-

5287 in combination with a torque wrench as

shown in figure 5-143.

142 and 5-141.

c.

Crankshaft

Damper

and

Oil

Filter

d. Oil Pan. Refer to figures 4-125, 5-137

through 5-135 and torque tighten oil pan bolts to

175

pound-inches

and

self-locking

nuts

to

225

pound-inches. Tighten four slotted nuts (C, fig.

Note.

During overhaul operations, con-

sideration must be given to engine model, when

1. Sparingly coat cylinder stud threads (A) on crankcase

assembling oil pan to engine. Engine Model

with antiseize thread lubricant FSN 9150-527-1752 or

AVDS-1790-2-M had an oil pan (10865039, fig.

9150-663-1770.

7-14) with oil drain plugs located specifically

C a u t i o n : If lubricant is extended to face of

designed for a certain vehicle and the engine

washer nut, reliable retaining torque cannot be

model

was

not

interchangeable

with

other

obtained.

vehicles. The oil pan (10912162, fig. 7-15) on

engine Models AVDS-1790-2-AM and AVDS-

2. Rotate engine crankshaft using engine turning splined

1790-2A provides an oil drain plug location that

wrench-5120-793-7895 (fig. 5-91) until the No. 1R

connecting rod (B) is at the top of its stroke.

is accessible in all vehicles. Although limited

3.

Remove

crankcase

protector-4910-795-7951

from

numbers of early oil pans are in current use, care

cylinder No. 1R mounting studs (C) being careful not

must be taken in Depot overhaul to identify the

to allow connecting rod to forceably drop against the

early

oil

pans

and

properly

designate

engine

c r a n k c a s e cylinder mounting surface or mounting

model.

studs.

4 . Remove piston pin from piston of No. 1R cylinder

assembly and place piston and cylinder over No. 1R

c o n n e c t i n g rod. Insert piston pin (D) with plugs

through connecting rod and piston and center pin in

position. Center piston pin plugs in piston.

5. Slide cylinder (E) over piston on crankcase studs and

temporarily secure with two extended washer nuts (fig.

on crankcase.

7-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |