|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-249-34&P

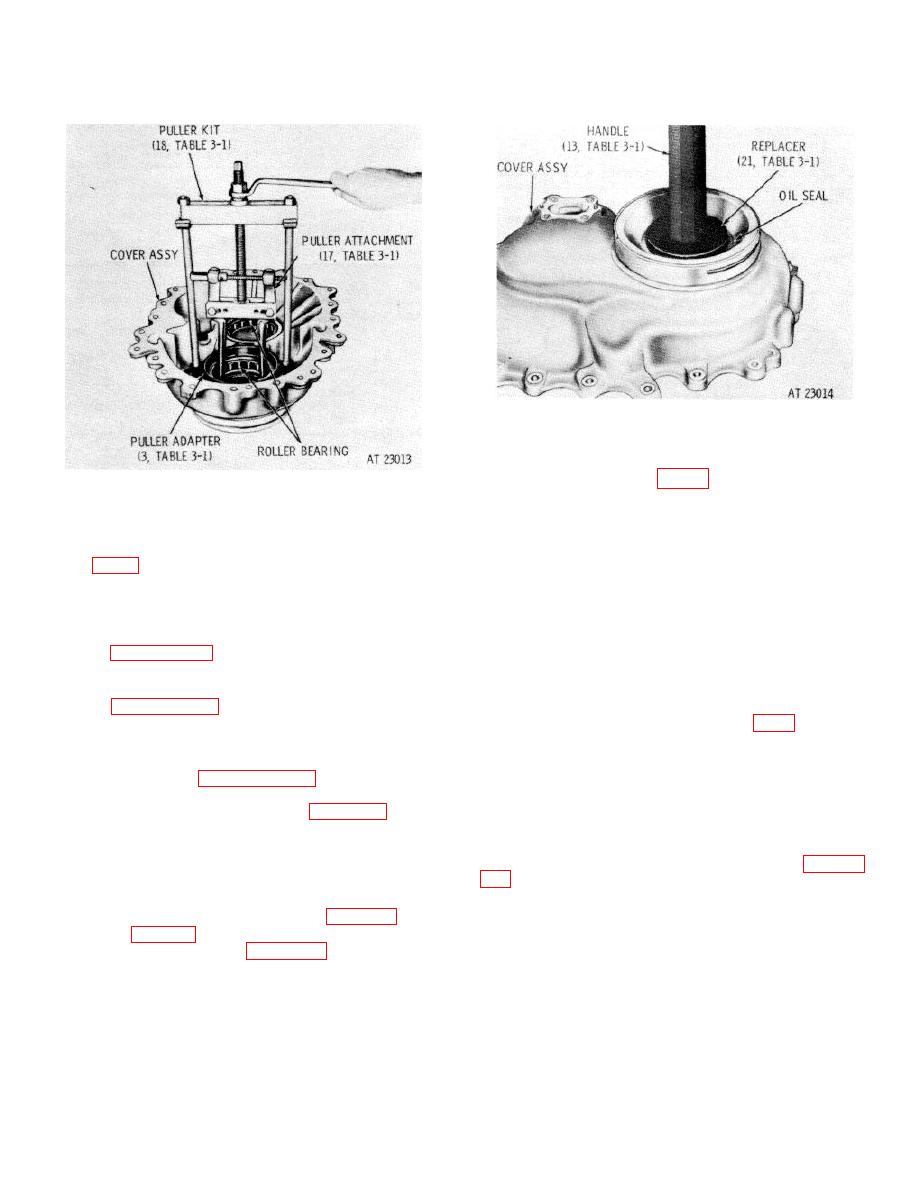

Figure 7-49. Installing output oil seal into end cover

assembly.

Figure 7-48. Removing roller bearing from end cover

new replacement part. Press the sleeve onto the cover,

beveled edge side first, until it is firmly seated against

assembly.

the cover.

c. If reduction drive and driven gear roller

e. Do not remove two screw thread inserts

bearings (69 and 85) were removed, install new

(83, FO-7) and two staking pins (84), unless

replacement parts. Chill the bearings in dry ice for 4

replacement of parts is necessary.

If necessary,

hours and heat the housing to 3500 F before installation.

remove the inserts and pins.

Make certain the bearings are fully seated when

installed.

7-124. Cleaning

NOTE

Refer to paragraph 5-2 for cleaning recommendations.

The cutout on the bearing race must

be indexed with the retaining plate

7-125. Inspection and Repair

location in the cover.

Refer to paragraph 5 3 for general inspection and repair

recommendations.

lockwasher (87) and bolt (88). Make certain the tab of

the lockwasher that is bent at right angle is inserted in

7-126. Repair Standards

the hole of the retaining plate. Bend the remaining two

a. Refer to paragraph 5 4 for explanation of

tabs against the flat sides of the bolt head.

repair standards.

e. If two screw thread inserts (83) and staking

b. Refer to repair standards (table 7-18).

pins (84) were removed, install new replacement parts

as follows: Select inserts for 0.002-inch tight to 0.002-

7-127. Assembly

inch loose fit. Install to the dimension given in figure 7-

(FO -7)

thread of the insert, and a sleeve with an outside

a. If oil seal (78) was removed, install a new

diameter smaller than the outside diameter of the insert,

replacement part. Using replacer (21, table 3-1) and

to install the inserts. The bolt should project through the

handle (13, table 3-1), press or drive the oil seal, spring

sleeve 1 1/4-inch for the 3/8-16 volts.

side first, into the end cover (figure 7-49).

7-41

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |