|

|||

|

|

|||

|

Page Title:

Section XXII. RIGHT OUTPUT END COVER ASSEMBLY AND SPEEDOMETER DRIVE COVER-REPAIR |

|

||

| ||||||||||

|

|

TM 9-2520-249-34&P

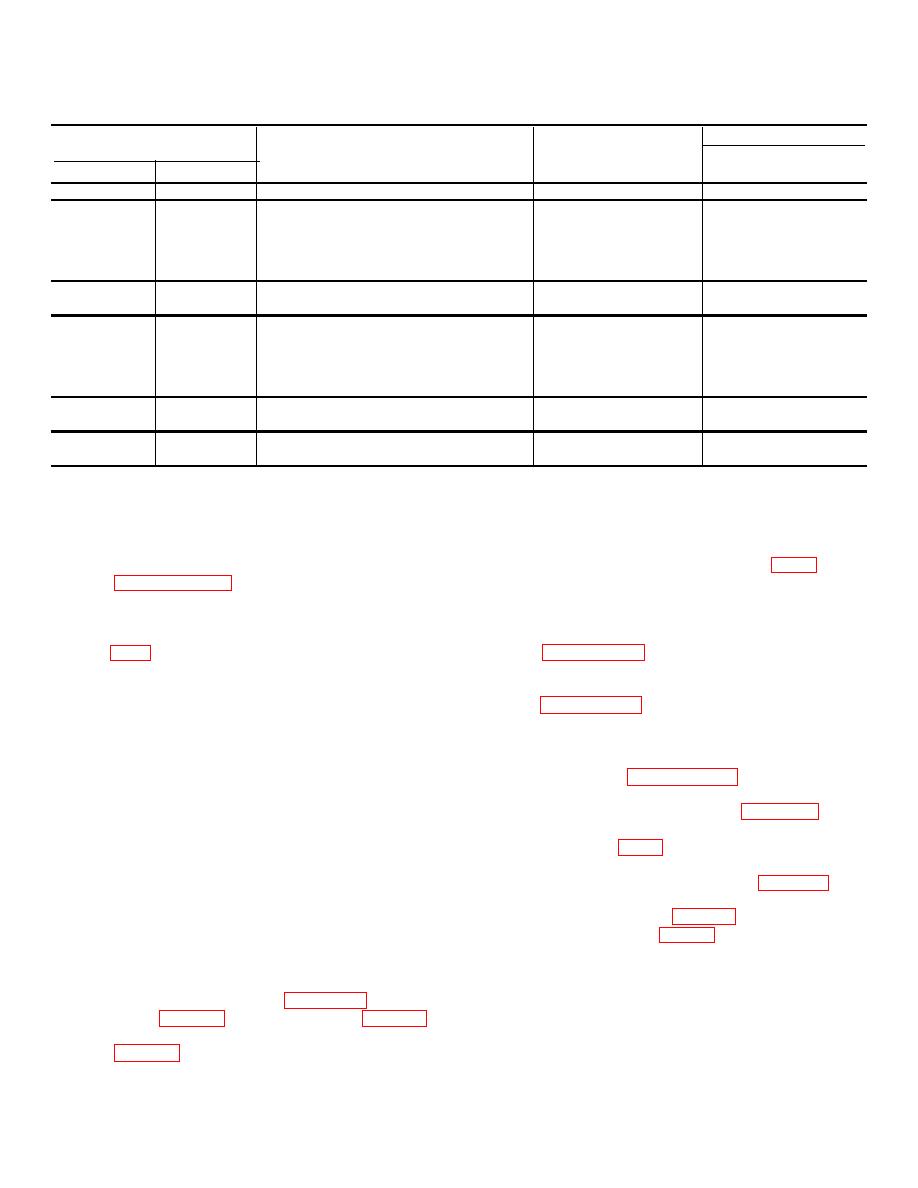

Table 7-18. Repair Standards Left Output End Cover)

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

7

64a

Outside diameter at bearing surface of gear 3.7518 to 3.7528

7

69a

Outside diameter of bearing .................

5.5133 to 5.5141

*

7

81a

Inside diameter at bearing surface of cover 5.5106 to 5.5118

5.5123

7

69a,

Fit of bearing in cover ...........................

0.0015T to 0.0035T

81a

7

80a

Outside diameter of sleeve (installed) ...

7.999 to 8.003

7.990

7

81b

Inside diameter at bearing surface of cover 5.5106 to 5.5118

5.5123

7

85a,

Outside diameter of bearing .................

5.5133 to 5.5141

*

7

81 b.

Fit of bearing in cover ..........................

0.0015T to 0.0035T

85a

7

90a

Outside diameter at bearing surface of gear 3.7518 to 3.7528

*

7

90b

Outside diameter at lip seal surface of gear 3.5000 to 3.5005

3.4980

*Replace when worn beyond new dimensions.

Section XXII. RIGHT OUTPUT END COVER ASSEMBLY AND

SPEEDOMETER DRIVE COVER-REPAIR

7-128. Description

speedometer drive cover (4), unless replacement is

Refer to paragraph 2-26 for description of the right

necessary. If necessary, remove the oil seal.

output end cover assembly.

7-130. Cleaning

7-129. Disassembly

Refer to paragraph 5-2 for cleaning recommendations.

a. Do not remove oil seal (53) from output

end cover (46) unless replacement is necessary. If

7-131. Inspection and Repair

necessary, remove the seal.

Refer to paragraph 5 3 for general inspection and repair

b. Do not remove sleeve (49) from output end

recommendations.

cover (46) unless replacement is necessary.

If

necessary, remove the sleeve.

7-132. Repair Standards

c. Do not remove two speedometer drive

cover mounting pad dowel pins (50) unless replacement

repair standards.

is necessary. If necessary, remove the dowel pins.

d. Do not remove four screw thread inserts

(51) and four staking pins 152) unless replacement is

necessary. Do not remove two screw thread inserts (47)

a. If oil seal (53) was removed, install a new

and two staking pins (48) unless replacement is

replacement part. Using replacer (21, table 3-1) and

necessary. If necessary, remove the inserts and pins.

handle (13, table 3 1), press or drive the oil seal, spring

e. Do not remove reduction drive and driven

side first, into the end cover fig. 7-49).

gear roller bearing (15 and 40) from output end cover

(46), unless replacement is necessary. If necessary,

new replacement part. Press the sleeve onto the cover,

flatten tab lockwasher (42) and remove bolt (41), tab

beveled edge first. until firmly seated against the cover.

lockwasher (42) and retaining plate (43).

c. If two speedometer drive cover mounting

f.

Using adapter (3, table 3-1), puller

pad dowel pins (50) were removed, install new

attachment (17, table 3-1), and puller kit (18, table 3-1),

replacement parts. Press them into the mounting pad

remove the reduction drive and driven gear roller

so that they project 0.220 from the face of the pad.

bearings (fig. 7-48).

d. If four screw thread inserts (51) and four

7-42

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |