|

|||

|

|

|||

|

Page Title:

Nondestructive Inspection (Visual Inspection) |

|

||

| ||||||||||

|

|

TM 750-245-4

suspect an open weld, it is permissible to "probe" the

connection. However, force to the weld must be applied

with caution to avoid stressing the weld.

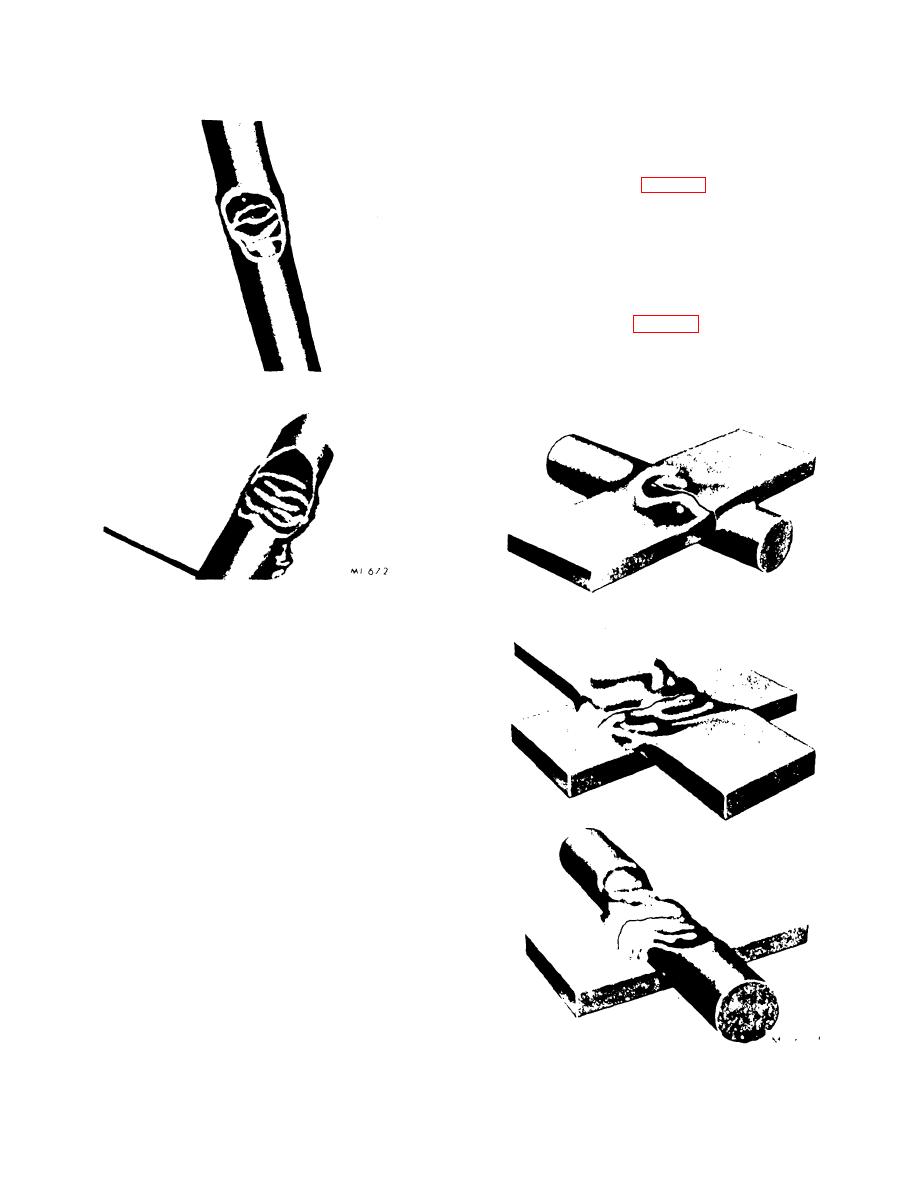

8-16. Offcenter Weld (Fig. 8-3)

A weld in which either or both of the materials were not

centered between the electrodes.

This type weld

normally causes excessive metal expulsion. In some

cases, if high electrode force has been used, the

offcenter weld can be detected visually by the location

of the indentations of the electrodes.

8-17. Cracked Weld (Fig. 8-4)

Any weld which exhibits a crack in the weldment or

adjacent to it. Cracks normally appear along the fillet or

across the weld area. Cracks are caused by excessive

pressure and / or heat.

Figure 8-3. Offcenter welds.

8-14. Nondestructive Inspection (Visual Inspection)

a. The visual inspection is the only method

available at the present time to nondestructively

evaluate welding repairs. In some cases, a defective

weld can be detected by the unaided eye, but in most

cases an optical aid is required to detect minute defects.

To evaluate the welds visually, illustrations are included

to serve as a guide for the inspector. The inspector

must also exercise his own judgement based on

experience in marginal cases.

b. Every weld in a module must be visually

inspected using an optical aid having a minimum

magnification of 30 power. This necessitates that a

module be inspected in-process at selected points

during fabrication as some welds are inaccessible upon

completion of the package. Upon completion of the

package, all accessible welds should be reexamined to

determine if any damage has resulted from handling

during fabrication.

8-15. Open Weld

A point where a weld has been attempted but no fusion

or forging action has occurred due to misfire of the

welding machine, or a point where a weld is specified by

drawing but has been overlooked by the operator.

Figure 8-4. Cracked welds.

When microscopic examination leads the inspector to

8-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |