|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 750-245-4

the result of too much pressure.

The excessive

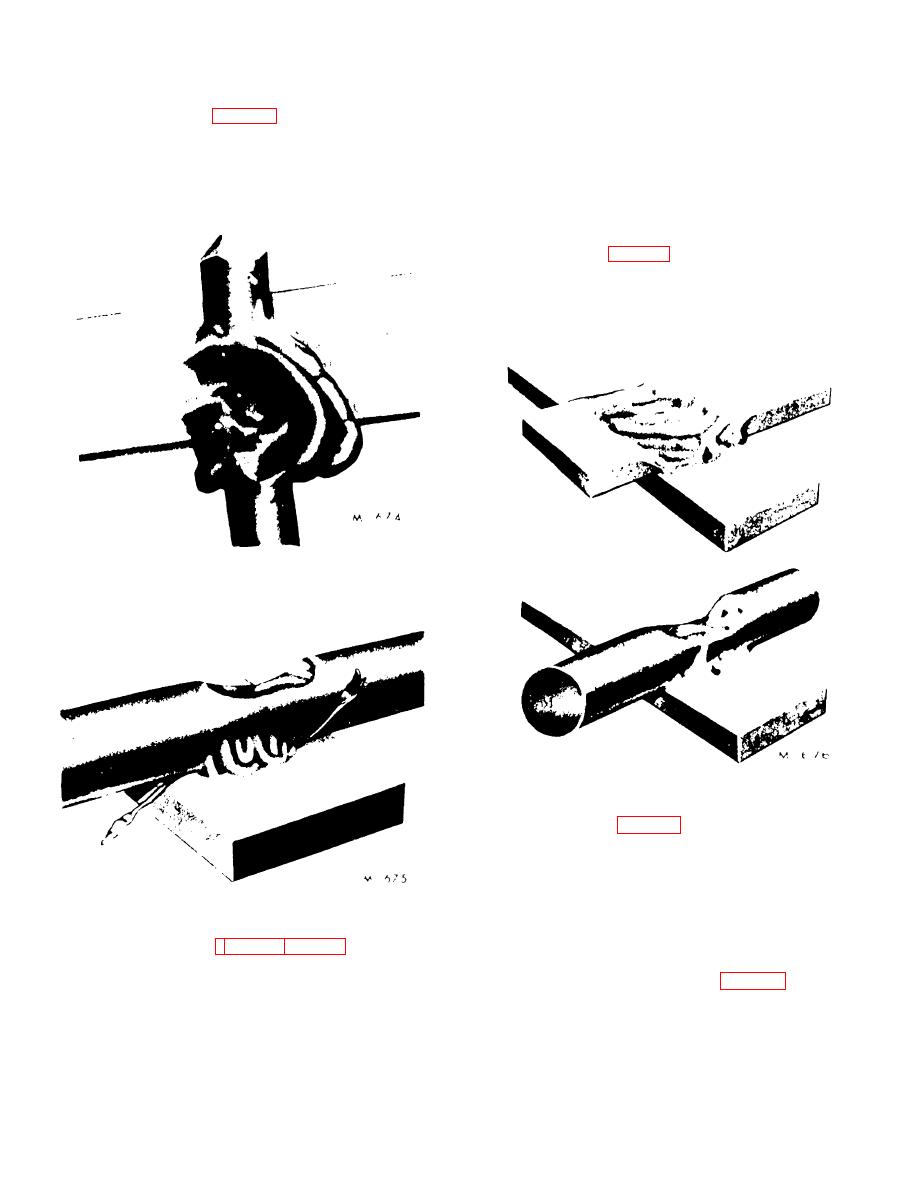

8-18. Deformed Weld (Fig. 8-5)

pressure forces the material to form a bulge while it is in

A deformed weld is one in which the diameter or

the plastic stage. A slight amount of bulging is not

thickness of either of the materials has been reduced by

considered to be detrimental. Splattering and fragments

more than 50 percent or the total reduction of both

of metal extending from the weld zone are actual cases

materials is greater than 35 percent. Deformation is

of metal expulsion and occur because of excessive

caused by excessive pressure and / or heat.

pressure and / or heat.

8-20. Blow Hole (Fig. 8-7)

A weld in which holes are evident, usually along the

fillet.

These holes are readily detectable under

magnification. Blow holes result from the formation of a

gas pocket in the weld zone which reaches such high

internal pressures that metal is expelled.

Figure 8-5. Deformed welds.

Figure 8-7. Blow hole.

8-21. Pitted Weld (Fig. 8-8)

A weld that exhibits "pits" in either or both of the

materials being joined. In certain cases, when surface

fusion occurs, the molten metal adheres to the electrode

(termed "sticking"). As the electrode force is released,

Figure 8-6. Splatter weld.

the material which as adhered to the electrode is pulled

from the parent metal, resulting in a rough and pitted

8-19. Metal Expulsion (Figs. 8-5 and 8-6)

surface.

A weld which exhibits either excessive bulging of metal

at the interface, "splashed" metal deposits on the

8-22. Excessive Surface Fusion (Fig. 8-9)

adjoining element, or fragments extending from the weld

A weld in which the weld material has melted to an

interface. Metal bulging (sometimes referred to as

excessive degree at the point of interface with the

distortion) is not metal expulsion in the true sense of the

electrode. A contact resistance exists at this point. If

word. It appears along the interface of the weld and is

this resistance is higher than that at the weldment

8-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |