|

|||

|

|

|||

|

Page Title:

SECTION III. INSPECTION AND SERVICING |

|

||

| ||||||||||

|

|

TM 55-4940-353-13&P

SECTION III. INSPECTION AND SERVICING

3-3

Daily Inspection. The pressure gages and the

air connection must be disconnected and the top cover

sight gage on the Hose Tester (7, 12, 15 & 16, figure 2-

of the reservoir removed. If replacement of the filter

element is required, the gaskets which seal the top and

damage repaired. The air filter (2) should be checked

bottom of the element must also be replaced.

for contamination. If necessary, clear the air filter

through the bottom bleed valve. Check the oil level in

b. Pressure Cages (7, 15 & 16). Remove the

the air lubricator (8) and if less than one-quarter full, fill

gages from the Hose Tester, and using a master gage to

with SAE-10 oil. Check the oil level in the reservoir (5)

obtain a known pressure, apply a pressure equal to

through sight gage (20) and replenish if necessary.

approximately half scale to each gage. If a gage

Check the pump and fittings for evidence of external

indication is incorrect remove the glass cover and reset

leakage and repair as required.

the pointer for the correct value. Gage accuracy is + 3

percent of full scale.

3-4.

Periodic Inspection. The design and nature of

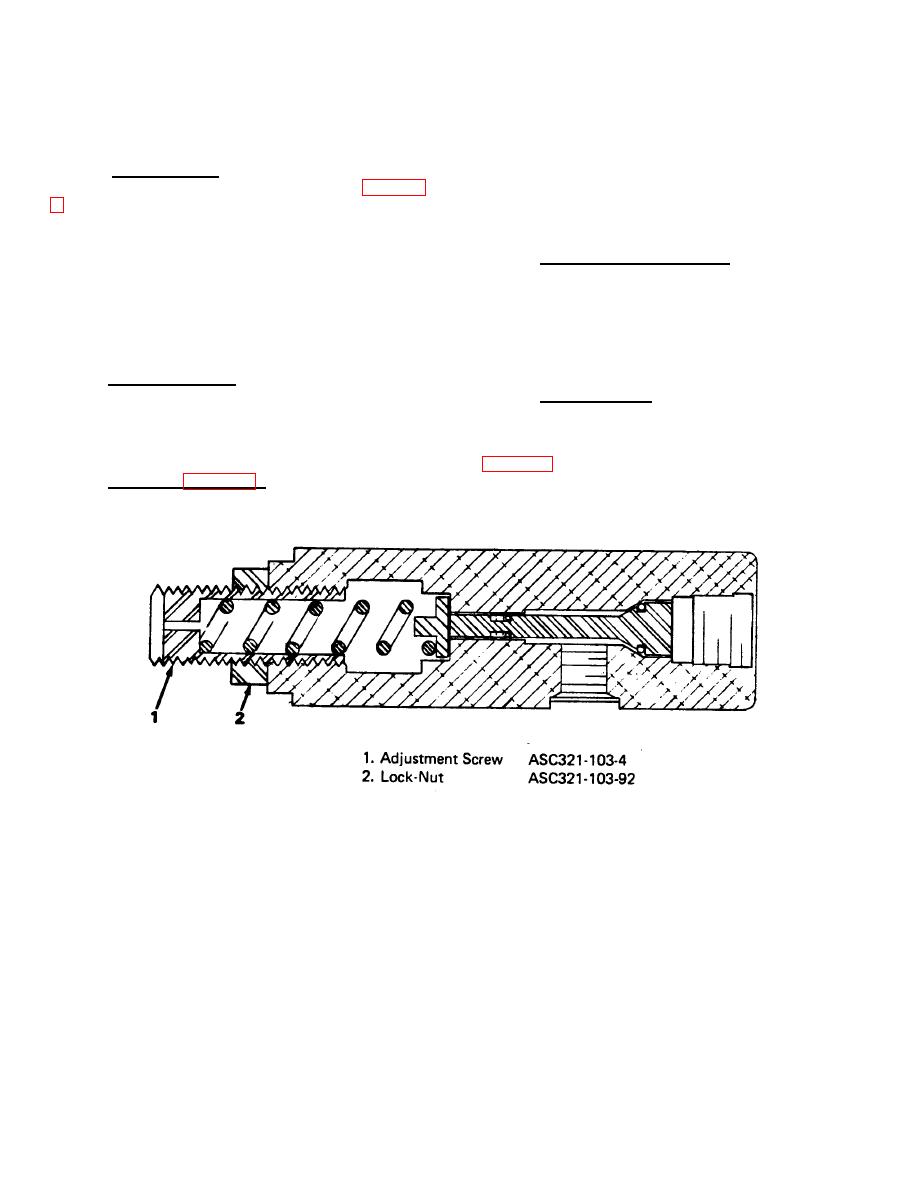

c. Gage Saver (17). Apply a known pressure, as

the Model 321 Hose Tester is such that a periodic

inspection need only be accomplished at six-month

read on oil pressure gage (16), to the unit and note the

intervals. At this time the following components of the

pressure at which it actuates. This pressure should be

unit should be checked:

2800 + 100 psig. If adjustment is necessary, refer to

adjustment screw (1) clockwise to increase the setting;

a. Oil Filter (6, figure 2-1). Check the oil filter for

contamination. To gain access to the oil filter, the shop

counterclockwise to decrease.

Figure 3-1. Gage Saver Adjustment

3-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |