|

|||

|

|

|||

|

Page Title:

PROCEDURE FOR MANIFOLD PRESSURE TEST, VACUUM 30 - 10 INCHES OF HG ABS. |

|

||

| ||||||||||

|

|

TM 55-4920-416-13

Section IV

NAVAER 17-15C-539

to be tested, as indicated in paragraphs 4-34 and 4-35.

4-55. PROCEDURE FOR MANIFOLD PRESSURE TEST,

b. If the altitude of the station at which the checking is

VACUUM 30 - 10 INCHES OF HG ABS.

done is less than 75 feet above sea level, proceed in the same

a. Set PRESSURE selector valve at OFF.

manner as in paragraph 4-44 and 4-48. For a given Mach

b. Open PRESSURE control valves 3 and 4.

Number Setting on the outer dial of the MACH-AIRSPEED

c. Set VACUUM selector valve at 30 - 10 INCHES

INDICATOR, the Maximum Allowable Airspeed pointer should

MANIFOLD ABS. PRESSURE.

indicate the maximum allowable airspeed corresponding to

d. Close VACUUM control valves 1 and 2.

each altitude as given in Table 4-1, Col. #2.

e. Throw power switch to ON.

c. If the altitude of the station at which the checking is

f. Slowly open the VACUUM increase control valve 2.

being done is more than 75 feet above sea level, proceed by

The manifold pressure indicator pointer will rotate

bringing the ALTIMETER to an altitude of 5,000 feet in the

counterclockwise indicating a decrease in simulated manifold

same manner as in paragraph 4-38. Now proceed to increase

pressure.

pressure in order to bring the Airspeed Indicator up to points in

g. Open the VACUUM increase control valve until the

Column 1 in the same manner as in paragraphs 4-44 and 4-48.

manifold pressure indicator pointer stabilizes at the required

For a given Mach Number setting on the dial of the

check point.

MACH-AIRSPEED INDICATOR under test, the Maximum

h. Stabilize the manifold pressure indicator at the

Allowable Airspeed pointer should indicate the maximum

required check points, listed on the calibration card, by opening

allowable airspeed corresponding to each altitude as given in

the VACUUM decrease control valve 1.

Table 4-1, Column 3.

i. After completing all check points on the manifold

pressure indicator, throw power switch to OFF.

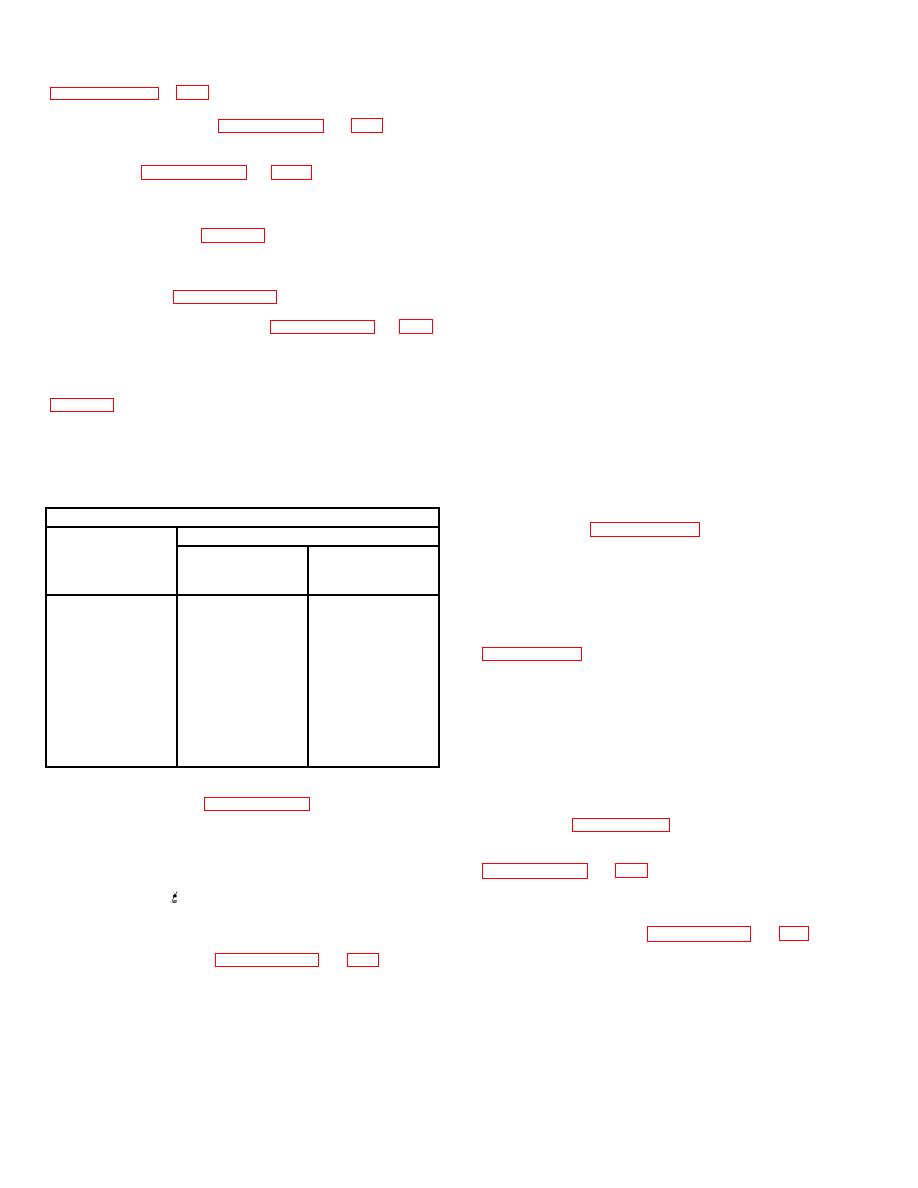

TABLE 4-1

j. Slowly open vacuum control valves 1 and 2 until all

instruments return to normal.

MAXIMUM ALLOWABLE AIRSPEED

k. Set VACUUM selector valve at OFF.

CALIBRATION CHART

4-56. CALIBRATE MANIFOLD PRESSURE, VACUUM 30 - 10

INCHES OF HG ABS. Adjust VACUUM control valves in

Column 1

Column 2

Column 3

accordance with paragraph 4-54. Set the master manifold

Knots Indicated Airspeed

pressure indicator at each point shown on the calibration card.

At

Mach No.

Enter the readings of the instrument under test on the

0 Feet

At

calibration test card provided.

Sea Level

5000 Feet

.5

330

4-57. CASE LEAK TEST, MANIFOLD PRESSURE, VACUUM

.55

364

30 - 10 INCHES OF HG ABS.

.6

397

363

a. Adjust vacuum control valves in accordance with

.65

430

390

.7

463

426

10 inches of Hg.

.75

497

447

b. Close needle valve on hose assembly to instruments

.8

529

488

being tested.

.85

562

519

c. Observe the manifold pressure indicator being tested;

.9

595

550

the pointer should not move more than 1/16 inch of Hg in 60

.95

628

570

seconds. A reading in excess of this indicates a possible case

1.0

661

613

leak and will necessitate removal of the instrument.

d. Slowly open needle valve on hose assembly to

4-53.

CALIBRATE MAXIMUM ALLOWABLE AIRSPEED.

instruments being tested.

Follow the procedure in paragraph 4-52. On the calibration

e. Return instruments to normal position according to

card for the instrument under test, note the corresponding

instructions in paragraph 4-54.

Maximum Allowable Airspeed pointer readings.

After

completing the calibration, compare the readings with those

4-58. Remove test hose connections in accordance with

given in either the Column 2 or 3 for the critical Mach Number

setting of the instrument being tested. Instruments having

errors greater than 10 knots should be replaced.

4-59. MANIFOLD PRESSURE TEST, PRESSURE, 30 - 75

INCHES OF HG ABS. Connect the test set to the instruments

4-54. MANIFOLD PRESSURE TEST, VACUUM 30 - 10

to be tested as indicated in paragraphs 4-34 and 4-35.

INCHES OF HG ABS. Connect the test set to the instruments

to be tested as indicated in paragraphs 4-34 and 4-35.

4-60. PROCEDURE FOR MANIFOLD PRESSURE TEST,

PRESSURE, 30 - 75 INCHES OF HG ABS.

a. Set PRESSURE selector valve at 30 - 75 INCHES

MANIFOLD ABS. PRESSURE.

b. Close PRESSURE control valves 3 and 4.

c. Set VACUUM selector at OFF.

d. Open VACUUM control valves 1 and 2.

18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |