|

|||

|

|

|||

|

Page Title:

FIGURE 4-88. Correctly De-Glazed Surface. |

|

||

| ||||||||||

|

|

TM 55-1905-223-24-4

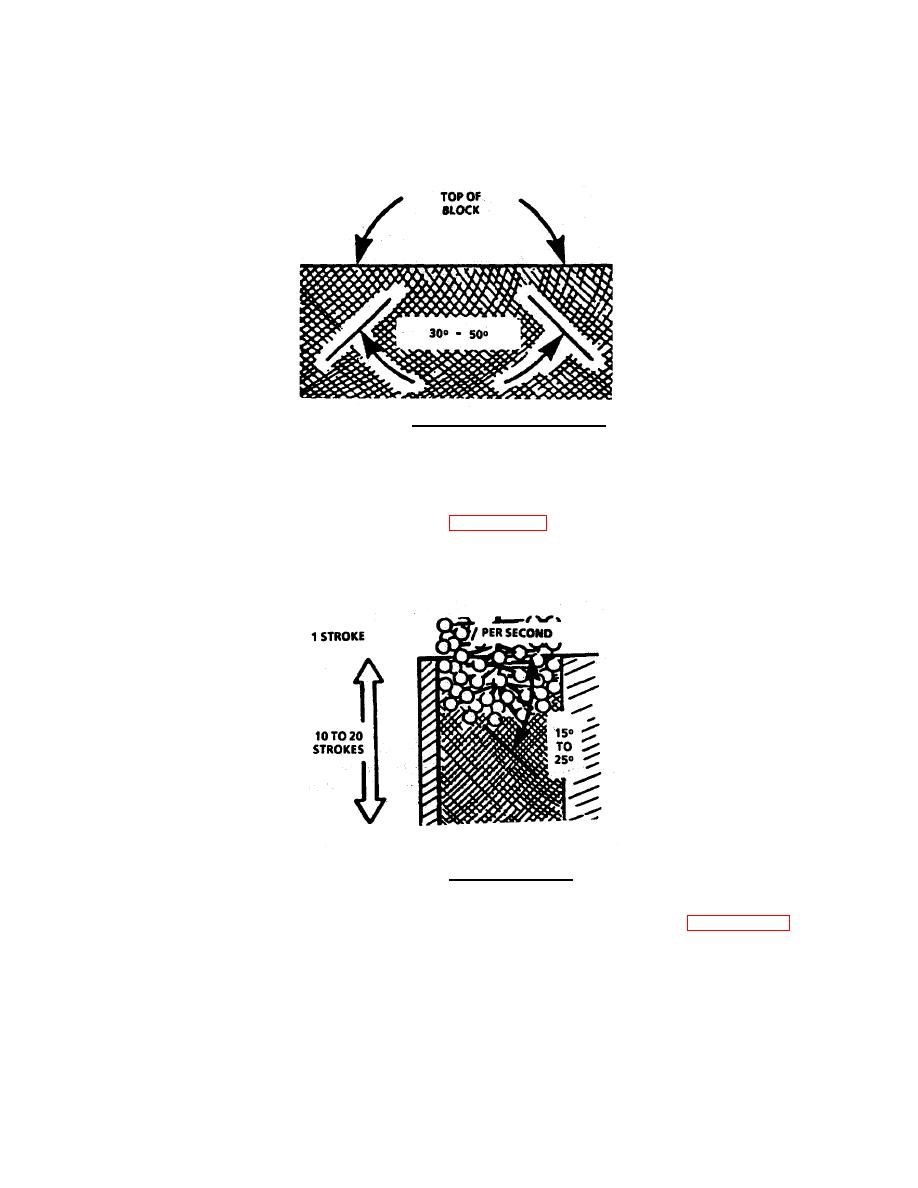

A correctly de-glazed surface (FICURE 4-88) will have a crosshatched appearance with the lines at 15 to 25-degree

angles with the top of the cylinder block, 30 to 50-degree included angles on crosshatch.

FIGURE 4-88. Correctly De-Glazed Surface.

e. Use a drill, a fine grit flexi hone and a mixture of equal parts of solvent and SAE 30W engine oil to de-glaze the

bores.

(1) Make vertical strokes, 1 stroke per second. Drill 300 to 400 RPM. The crosshatch angle is a function of fill

speed and how fast the bore is moved vertically (FIGURE 4-89).

(2) Inspect bore after 10 strokes. The degree of angle should be 15 to 25

.

FIGURE 4-89. De-Glazing Bores.

(3) A sizing bore can be used to remove minor grooves or to correct minor out-of-taper (FIGURE 4-90). Taper

should be 0.003 inch (0.076mm).

4-62

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |