|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(3) Smooth minor rough spots, scratches,

for shorts or grounds with an ohmmeter.

and nicks from inside bore of sleeve

b e a r i n g using a fine stone or crocus

ings are defective.

cloth dipped in dry cleaning solvent.

(2) I n s p e c t contact assembly for cracks,

b . Repair of Commutator End Plate.

w a r p a g e , or broken springs. Replace

contact assembly if defective. Inspect

(1) S m o o t h minor scratches, burs, and

contacts on terminal studs for burning

dents on machined surfaces of end plate

or pitting. Replace studs if contacts are

using a fine mill file.

defective.

(2) Repair damaged threads of end plate.

i. Inspection

of

Frame

Assembly.

(3) Smooth minor rough spots, score marks,

(1) Inspect frame for cracks or distortion.

and scratches in inside bore of sleeve

R e p l a c e frame if defective. Inspect

b e a r i n g using a fine stone or crocus

tapped holes in frame. Replace frame

cloth dipped in dry cleaning solvent.

if threads are stripped or damaged be-

yond repair.

c . Repair of Brush Holder Assembly.

(2) Check field coils for insulation break-

down with ohmmeter. Attach one probe

(1) I n s p e c t insulations, plates, spacers,

of the ohmmeter to the frame and the

a n d brush holders for distortion and

other probe to one of the field coil ter-

cracks. Replace defective parts.

m i n a l s . The minimum reading should

not be less than one megohm. Replace

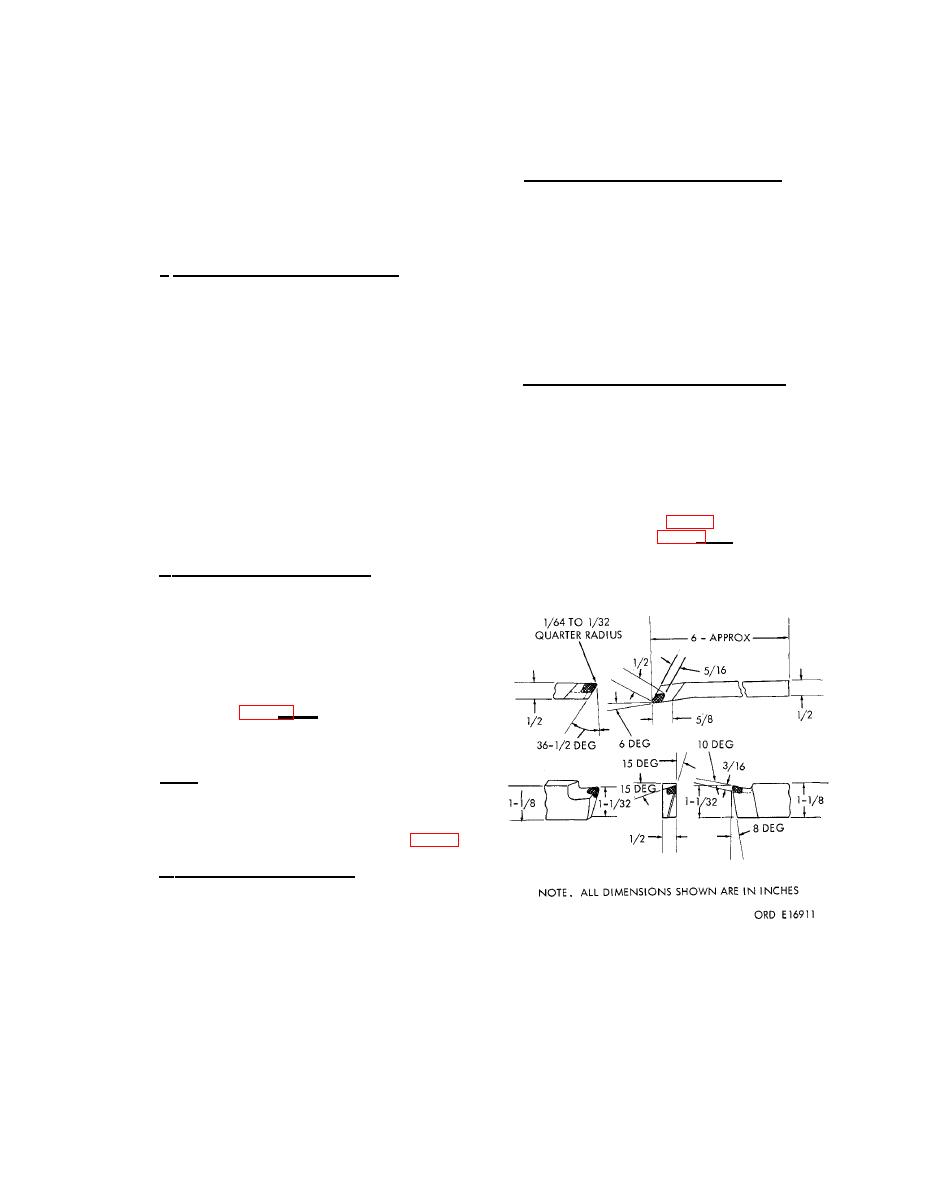

(2) Check brushes for cracks and excessive

defective coils.

w e a r . Check springs for cracks and

d i s t o r t i o n . Check brushes and spring

(3) I n s p e c t terminal screw for damaged

tension (step 1, fig. 10) for conformity

threads. Replace if threads are stripped

to wear limits (par. 41a). If any brushes

or damaged beyond repair.

a r e defective, replace entire set with

brush kit. Replace springs if they do

j. Thrust Washer and Spacer.

not conform to wear limits.

(1) I n s p e c t thrust washer and spacer for

cracked or deformed condition. Replace

defective parts.

(2) Check thickness of washer and spacer.

Replace washer or spacer if it does not

c o n f o r m to limits specified in wear

limits (par. 4 1 b ) .

27. REPAIR

Note. The following subparagraphs cover only

those parts wherein a repair operation will re-

turn the damaged part to serviceable condition.

Parts not detailed herein must be replaced when

they fail to pass the required inspection (par. 26).

a . Repair of Drive Housing.

(1) S m o o t h minor scratches, burs, and

d e n t s on machined surfaces of drive

housing using a fine mill file.

(2) Repair damaged threads in drive hous-

ing.

DIMENSIONS.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |