|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

Release lever and switch.

e.

shorts (fig. 30). Also examine the start-

er for armature drag.

If drag exists,

f.

Turn adjusting bolt one-half turn

check for loose pole shoe screws and tight-

away from lever as shown in figure 45.

en as necessary; or, disassemble the start-

er and check for armature eccentricity

Tighten locknut as shown in figure

(fig. 31) or faulty bearings.

g.

c.

If a low speed and low current con-

dition exists, inspect the starter for

faulty connections and for poor brush con-

tact (fig. 39).

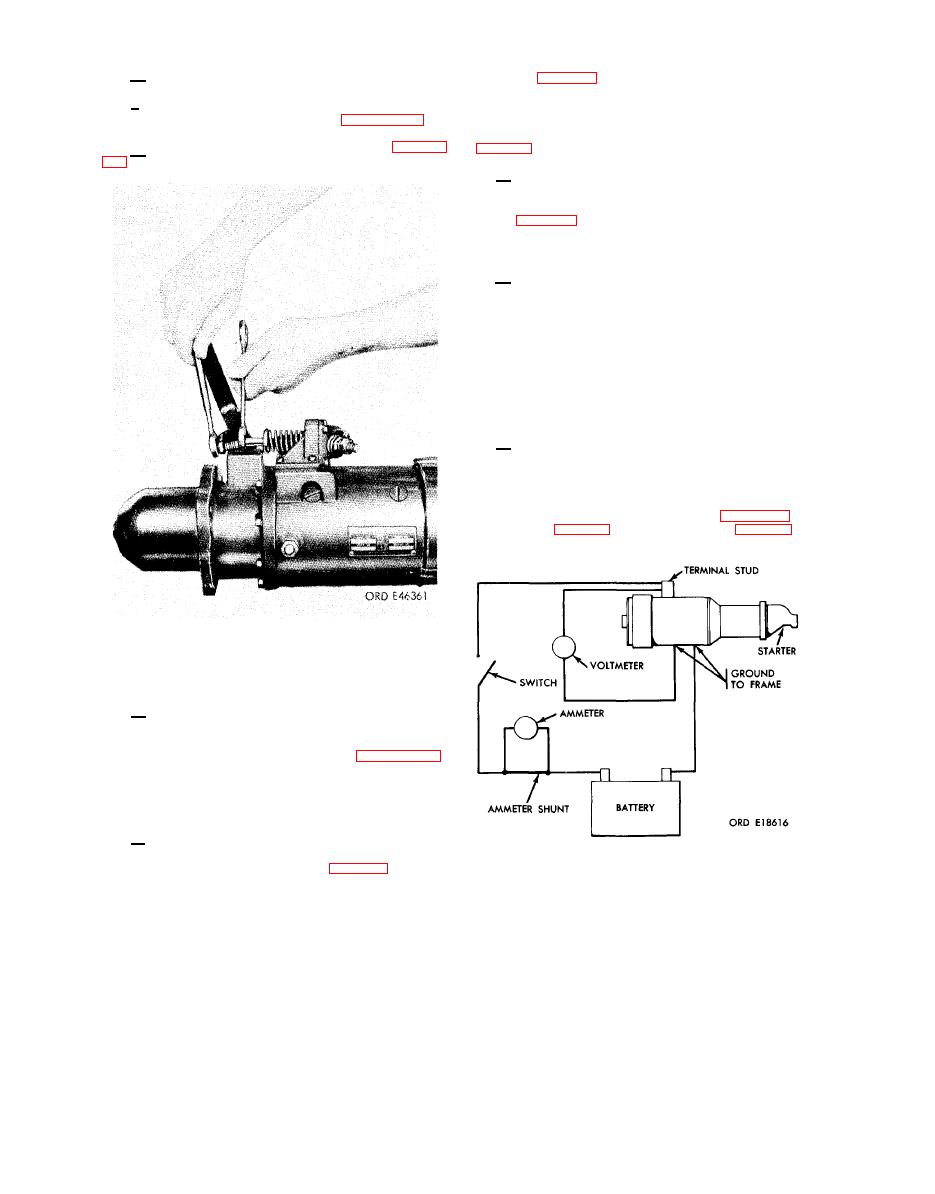

Connect the starter as shawn in fig-

a.

ure 47 and clamp starter down. Mount a

torque arm and tension gage on the start-

Close test switch and adjust volt-

er.

age to 4.0 volts.

Check the current draw

at the ammeter.

It should be 380 amps

maximum. Check the torque reading at the

tension gage. Multiply tension gage read-

ing by foot-length of torque arm to obtain

stall torque.

It should be 21.0 foot-

pounds minimum.

b.

If a high current and low torque

condition exists, check for shorts and

proper assembly of the starter components.

If a low current and low torque con-

c.

dition exists, check field coils (par. 26),

armature (fig. 29), and brushes (fig. 39).

Figure 46. Tightening locknut to

secure adjusting bolt.

No-load Test

a. Connect a 24 volt dc power source,

variable resistance voltmeter, 1,000 am-

pere ammeter, test switch, and the starter

to the test circuit as shown in figure 47.

Check the current draw at the ammeter at

20 volts. It should be 65 amps.

Measure

the speed of rotation of the armature. It

should be 5,300 rpm.

If a low speed and high current

b.

condition exists, check the armature for

excessive arcing, grounds (fig. 29), and

Starter test setup.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |