|

|||

|

|

|||

|

Page Title:

Section III. CLEANING, INSPECTION, AND REPAIR |

|

||

| ||||||||||

|

|

Removing or installing square bushing.

Section III.

CLEANING, INSPECTION, AND REPAIR

be taken to prevent dry-cleaning solvent

25. Cleaning

from contacting the brushes.

Wash all parts, except

a. General.

26. Inspection

those detailed in paragraphs 25b through

25e, in dry-cleaning solvent, Specifica-

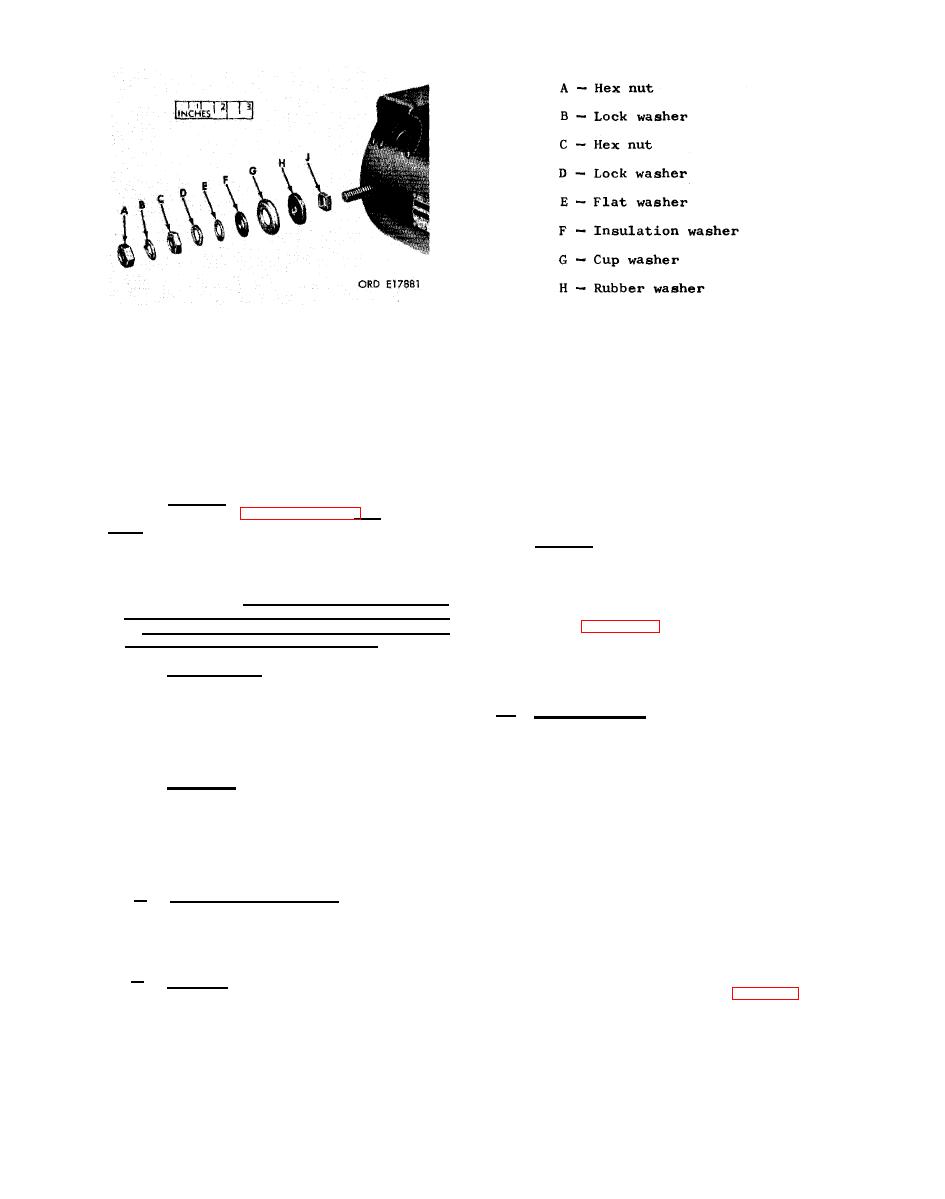

a. General. Inspect all screws, bolts,

tion P-S-661, or volatile-mineral-spirits

nuts, threaded holes, and plugs for worn

paint thinner, and dry with compressed

or damaged threads. Replace all worn or

air.

Inspect remaining hard-

damaged parts.

Warning:

Particles blown by com-

ware items and replace damaged parts.

pressed air are hazardous. Make certain

Note.

air stream is persons inaway from user

and any

directed

36 do not depict the armature used in

area.

the starter assembly; however, the pro-

cedures for testing and repairing the

b.

Field Coils.

Clean field coils

armature are the same.

and frame thoroughly with a cloth damp-

ened with dry-cleaning solvent or vol-

b.

Pinion Housing.

atile-mineral-spirits paint thinner. Be

careful not to damage protective insul-

(1) Inspect the pinion housing for

ation coating. Dry thoroughly with com-

cracks, distortion, and burs.

pressed air (15 psi max.).

Replace if damaged.

c. Armature. Remove loose particles

(2) Inspect the housing bushing-

from the armature and wipe with a clean

type bearing for score marks and

cloth dampened with dry-cleaning solvent

Check bearing

wear patterns.

or volatile~mineral-spirits paint thin-

against limits specified in re-

ner.

Clean commutator lightly with 00

pair and rebuild standards (par.

sandpaper and remove all dust with com-

40) and replace using a 0.87-

pressed air.

inch diameter arbor if worn be-

yond limits.

Brush Carrying Plate.

Clean the

d.

brush carrying plate with a brush and dry-

cleaning solvent or volatile-mineral-

(3) If the housing bushing-type

is removed, check the

spirits paint thinner and dry with com-

diameter of the bearing bore in

pressed air.

the pinion housing against the

e.

limits specified in the repair

Clean brushes with a

Brushes.

and rebuild standards (par. 40)

clean, ary cloth only. Extreme care must

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |