|

|||

|

|

|||

|

Page Title:

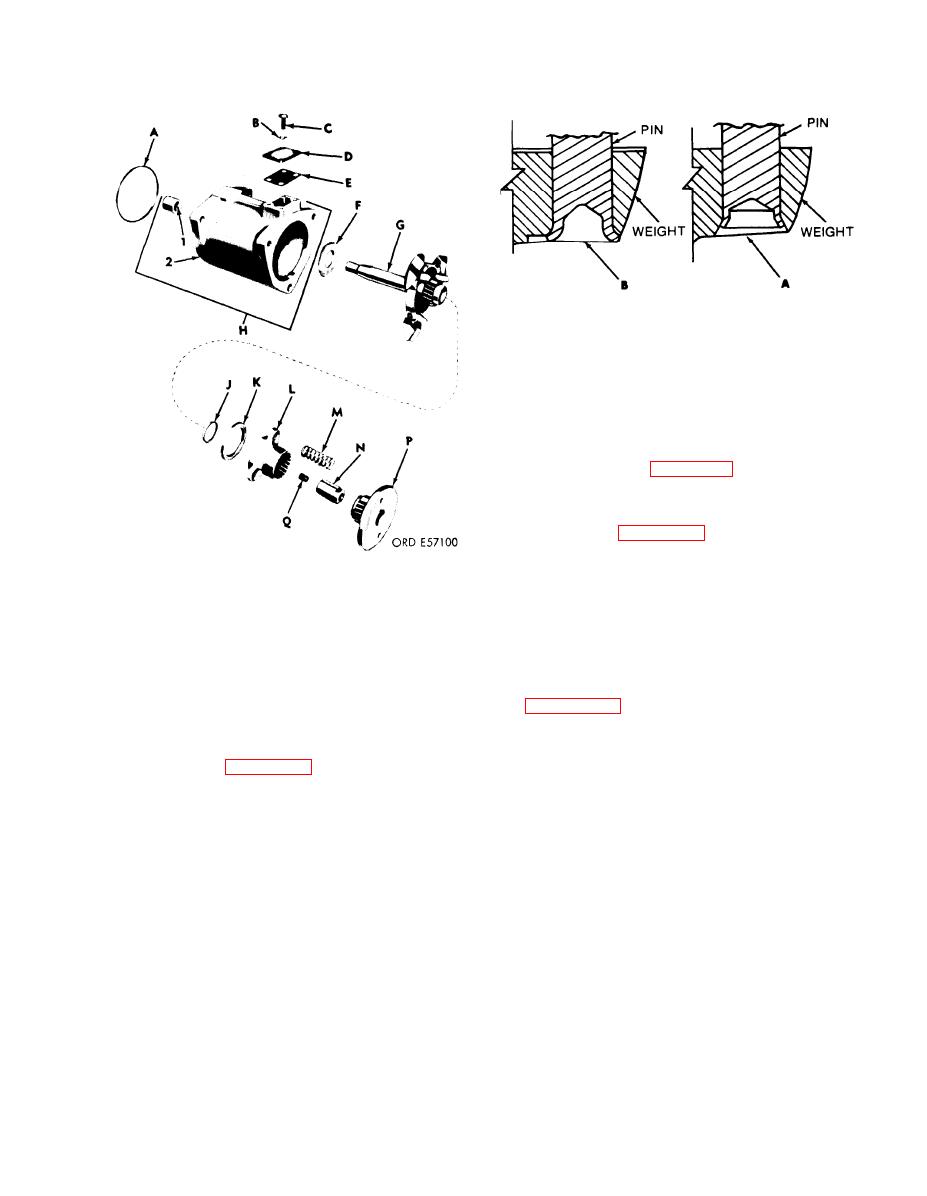

Figure 3-97. Timing device assembly, exploded view. |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

Figure 3-98. Comparison of timing device weight pins.

(5) Examine the weight on the spider assembly

(G) for freedom of movement. Replace the weight

and spider assembly when the weights do not move

freely.

Assemble the timing device

C . Assembly.

assembly as follows:

(1) The parts for the universal timing device

repair kit are listed in Appendix B. When any part in

the repair kit-- 5702661 except hardware items, must

be replaced, replace all parts applicable to the timing

device assembly.

(2) Refer to figure 3-97. Do not install timing

cover at this time. The timing device assembly parts

will be installed during assembly of pump.

Figure 3-97. Timing device assembly, exploded view.

3-28. Repair of Hydraulic Head Assembly.

(2) Inspect the timing device housing (H) for

cracks, nicks, burs, and damage to mating surfaces.

NOTE

Replace the housing when cracked. Minor nicks or

Except for the upper and lower head

burs may be cleaned up with crocus cloth.

preformed packings, component parts of the

(3) Inspect the splines of the weight and spider

hydraulic heads are not spare parts. If any

assembly (G), sliding gear (L), and timing device

part shows evidence of wear or other damage

hub (P) for damage, wear, and fit on mating sur-

replace the complete head assembly. Refer to

faces. Remove minor burs and scratches from splines

with crocus cloth. Replace all parts having splines

identified by American Bosch part number

which are damaged or do not fit properly with

HD9070A (FSN 2910-084-0259), used on

mating surfaces.

some code F pumps, are prone to cracking

(4) Refer to figure 3-98. Inspect the pins that

between the delivery valve screw and

secure the weights to the spider. Weight and spiders

cylinder No. 3 port. These heads must be

assembled with pin (A) should be discarded and

replaced upon disassembly of injection

replaced. Weight and spiders assembled with pin (B)

pump.

can be reused if the pins have no end play and are

tight.

3-61

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |