|

|||

|

|

|||

|

Page Title:

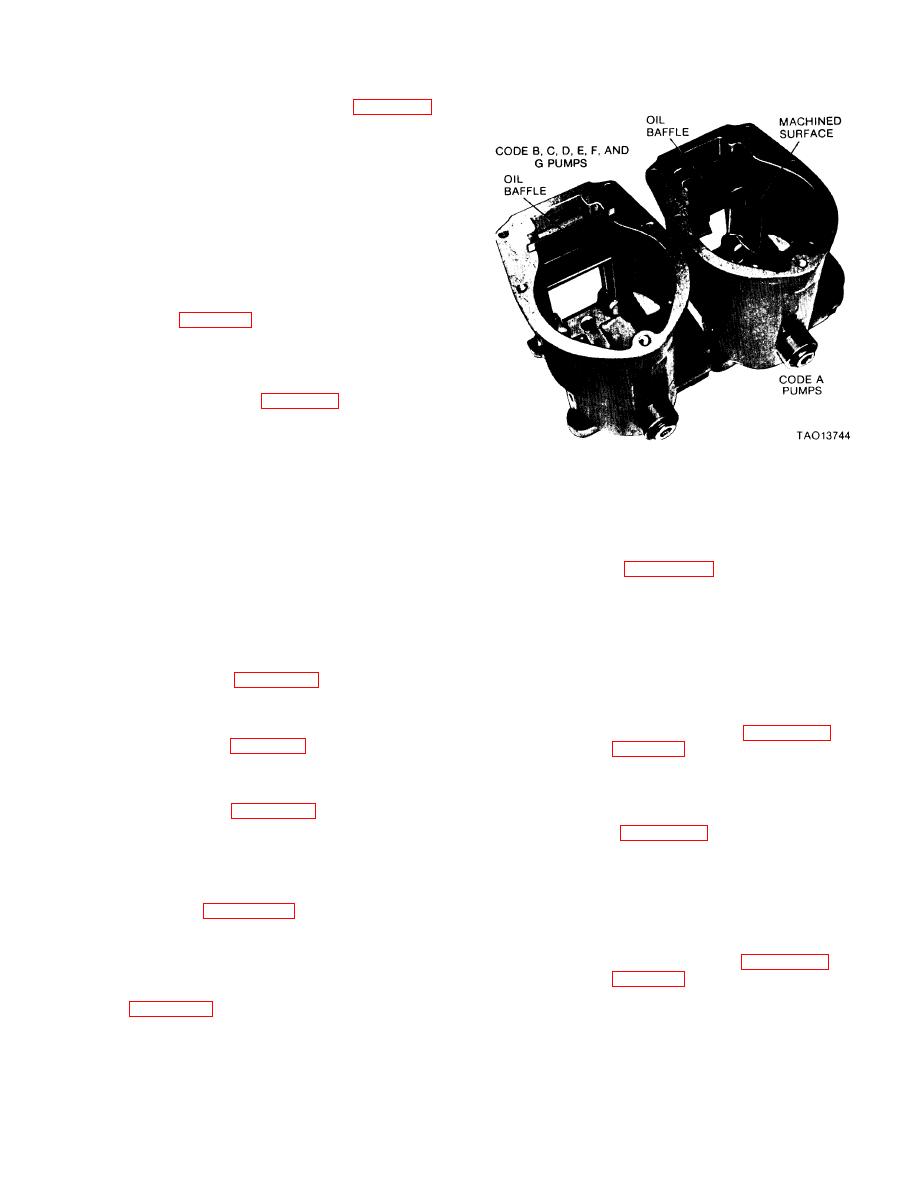

Figure 3-72. Identification of governor housings. |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

(5) Check sliding sleeve (B) against the limits

specified in the repair standards (para 3-60) and

replace the sleeve when it does not meet these

requirements. Inspect the bearing face of the sleeve

to determine the depth of any indentations. When

indentations exceed 0.008 -inch, replace the sliding

sleeve.

(6) Examine the operating shaft bearing (Z) for

burs, nicks, and scratches on the gasket surface and

hub diameter. Repair minor burs, nicks, and

scratches with a fine mill file or crocus cloth. Replace

the operating shaft bearing when any of these

conditions are excessive. Check the operating shaft

bearing against the limits specified in the repair

standards (para 3-60) and replace the bearing when it

does not meet these requirements.

(7) Inspect the operating shaft (FF) and shaft

spring plate (EE) for wear and replace any worn part

or parts. Check parts against the limits specified in

the repair standards (para 3-60) and replace parts

when they do not meet these requirements. Examine

the ends of the operating shaft spring (W) for wear

and indentations. When the spring ends are worn or

have indentations that exceed 0.004-inch, replace the

Figure 3-72. Identification of governor housings.

spring. Generally if the shaft is replaced, the bearing

NOTE

plate is also replaced.

Refer to (2) below for assembly instructions

(8) Inspect the smoke limit cam (C-6) for wear

on the fulcrum lever used on code A, B, C,

patterns and any other visible damage. Replace the

D, E, and F series pumps. Refer to (3) below

part when either condition exists.

for instructions on code G pumps.

(9) Inspect fuel control rod (C-2) and control rod

(2) Refer to figure 3-67. Code A pumps must

pin screw (C-5) for wear patterns and any other

have a fulcrum lever pivot pin dimension (X) of

visible damage. Replace parts when either condition

0.204. Code B, C, D, E, and F pumps must have a

exists.

fulcrum lever pivot pin dimension (X) of 0.165.

NOTE

Install setscrew (J). (Setscrew (J) is not used on code

Sub-paragraphs (10) and (11) below apply

C and D pumps. ) Assemble spacer (K) (spacer (K) is

only to code A injection pumps.

used only on code A pumps) and smoke limit cam

(10) Refer to figure 3-66. Inspect the operating

(H) on control rod pin screw (G) and install the

shaft torque link pivot pins (E) and shaft assembly

control rod pin screw on the fulcrum lever. Secure

(D) for wear and replace shaft assembly if any part is

with lock washer (F) and hex nut (E) after setting

worn, Check shaft against the limits specified in the

the smoke cam angle per table in figure 3-73. Use

repair standards (para 3-60).

improvised tool (figure 2-1 ) to set cam angle. Torque

NOTE

tighten hex nut (E) to 50-60 inch-pounds. Install

If operating shaft is replaced, replace shaft

spring (D) and washer (C) on control rod pin screw

bearing.

and install control rod (B). Secure with self-locking

(11) Refer to figure 3-66. Inspect pin slots, and

nut (A) torqued to 12 14 inch pounds.

stop pin on torque link (C) for wear, damage and

(3) Refer to figure 3-67. Code G pumps should

cracks. Replace torque link where showing wear or

have a fulcrum lever pivot pin dimension of 0.165.

damage.

Install setscrew (T) and hex nut (S). One or two

c. Assembly. Assemble the governor as follows:

threads of setscrew should extend beyond hex nut

NOTE

for preliminary adjustments. Assemble smoke limit

Refer to figure 3-72 for identification of

cam (U) on control rod pin screw (Q) and intall the

governor housings. All pumps use a pipe

control rod pin screw on the fulcrum lever. Secure

plug in the bottom of the governor housing

with lock washer (R) and hex nut (P) after setting

as shown.

the smoke cam angle per table in figure 3-73. Use

(1) The parts in the universal governor and

improvised tool (figure 2-1 ) to set cam angle. Torque

linkage repair kit 5702685 are listed and illustrated

tighten hex nut to 50-60 inch-pounds. Install fuel

in appendix B. The parts applicable to this governor

control rod (N), flat washer (M) and cotter pin (L).

and linkage must be used in repair of the governor.

3-49

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |