|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Valve Mechanism Maintenance Instructions (Cont)

This task covers:

a. Cleaning/Inspection

c. Assembly

b. Disassembly

d. Follow-on Maintenance

INITIAL SETUP

Models

References

All

None

Test Equipment

Equipment Condition

None

Condition Description

TM or Para

Special Tools

Cam follower on clean work

surface.

Set, dial indicator J7872

Gage, feeler FB310B

Special Environmental Conditions

Supplies

None

Solvent, dry cleaning, Item 60, Appendix C

General Safety Instructions

Oil, lubricating, Item 48, Appendix C

None

Personnel Required

Level of Maintenance

MOS 63W, Wheel vehicle repairer

Direct Support

a. Cleaning/lnspectlon.

WARNING

Adhesives, solvents, and sealing compounds can burn easily, can give off

harmful vapors, and are harmful to skin and clothing. To avoid injury or

death, keep away from open fire and use in well-ventilated area. If

adhesive, solvent, or sealing compound gets on skin or clothing, wash

immediately with soap and water.

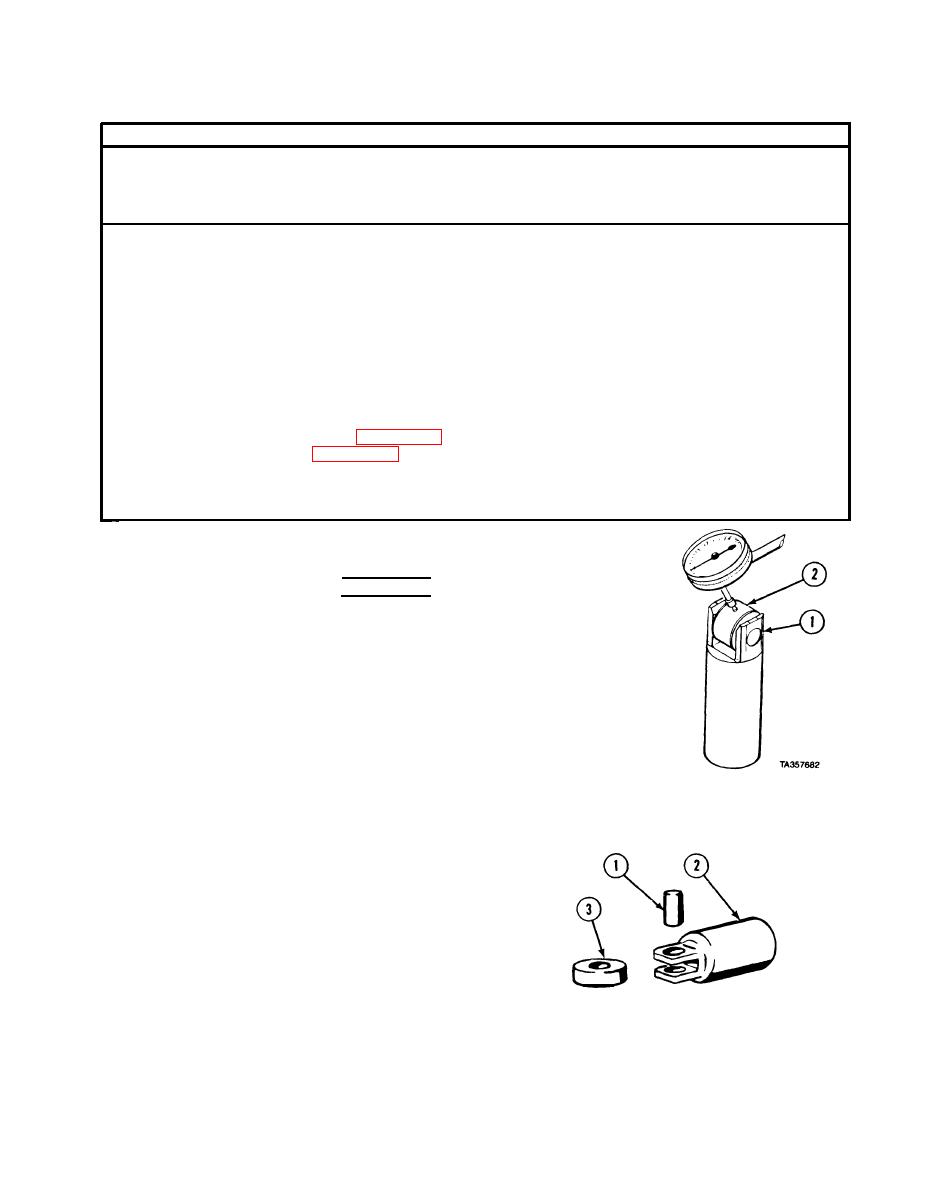

(1) Clean cam follower (1) with dry cleaning solvent.

(2) Inspect cam follower (1) for damage.

(3) Check side clearance between cam follower body (1) and roller (2) is

not more than 0.023 in. (0. 58 mm). If clearance is more than 0.023 in.

(0.58 mm) go to disassembly.

(4) Put cam follower in vise. Check for more than 0.010 in. (0.25 mm) pin-to-bushing clearance using

dial indicator. If clearance is more than 0.010 in. (0.25 mm), go to disassembly.

b . Disassembly.

NOTE

Pin and roller must be replaced together.

(1) Drive pin (1) out of cam follower body (2).

(2) Remove roller (3).

TA3S7683

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |