|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Piston and Connecting Rod Maintenance Instructions (Cont)

6-3. PISTON REPAIR.

This task covers:

c. Assembly

a. Disassemble y

d. Follow-on Maintenance

b. Cleaning/Inspection

INITIAL SETUP

Personnel Required

Models

MOS 63W, Wheel vehicle repairer

All

References

Test Equipment

None

Spring scale

Equipment Condition

Special Tools

Tool, piston pin retainer J23762

TM or Para

Condition Description

Gage set, piston J3174-02

Piston, connecting rod and

Gage, crown, piston J25397

liner removed.

Gage, piston groove J24599

Leak detector set J23987-01

Special Environmental Conditions

None

Supplies

Solvent, dry cleaning, Item 60, Appendix C

General Safety Instructions

Oil, lubricating, Item 48, Appendix C

None

Compound, international, No. 2, Item 26,

Level of Maintenance

General Support

Brush, paint, oval 1-1/4 in. (32 mm) size 12,

Item 10, Appendix C

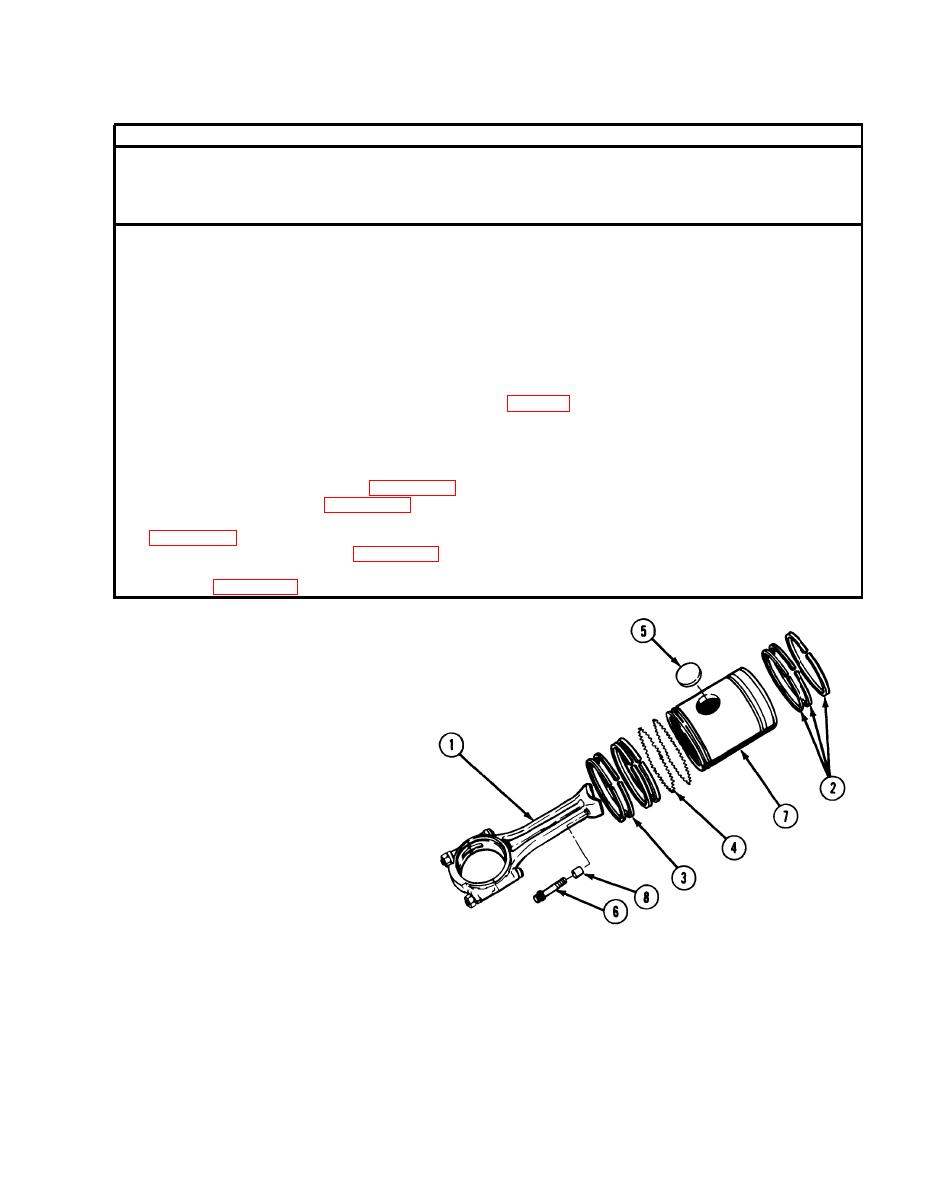

a. Disassembly.

(1) Place connecting rod (1) in vise

with soft jaws.

(2) Remove three upper piston

rings (2) using piston ring

remover and installer. Remove

four lower piston rings (3) by

hand.

(3) Remove oil ring expander (4)

from each lower piston ring

groove.

(4) Punch hole in two piston pin

retainers (5). Remove both

retainers.

(5) Loosen two screws (6).

(6) Remove connecting rod (1) and

piston (7) from vise.

(7) Remove two screws (6) and two

TA357429

spacers (8).

NOTE

Matchmark connecting rod before removal.

(8) Remove connecting rod (1) from piston (7).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |