|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Cylinder Head Maintenance Instructions

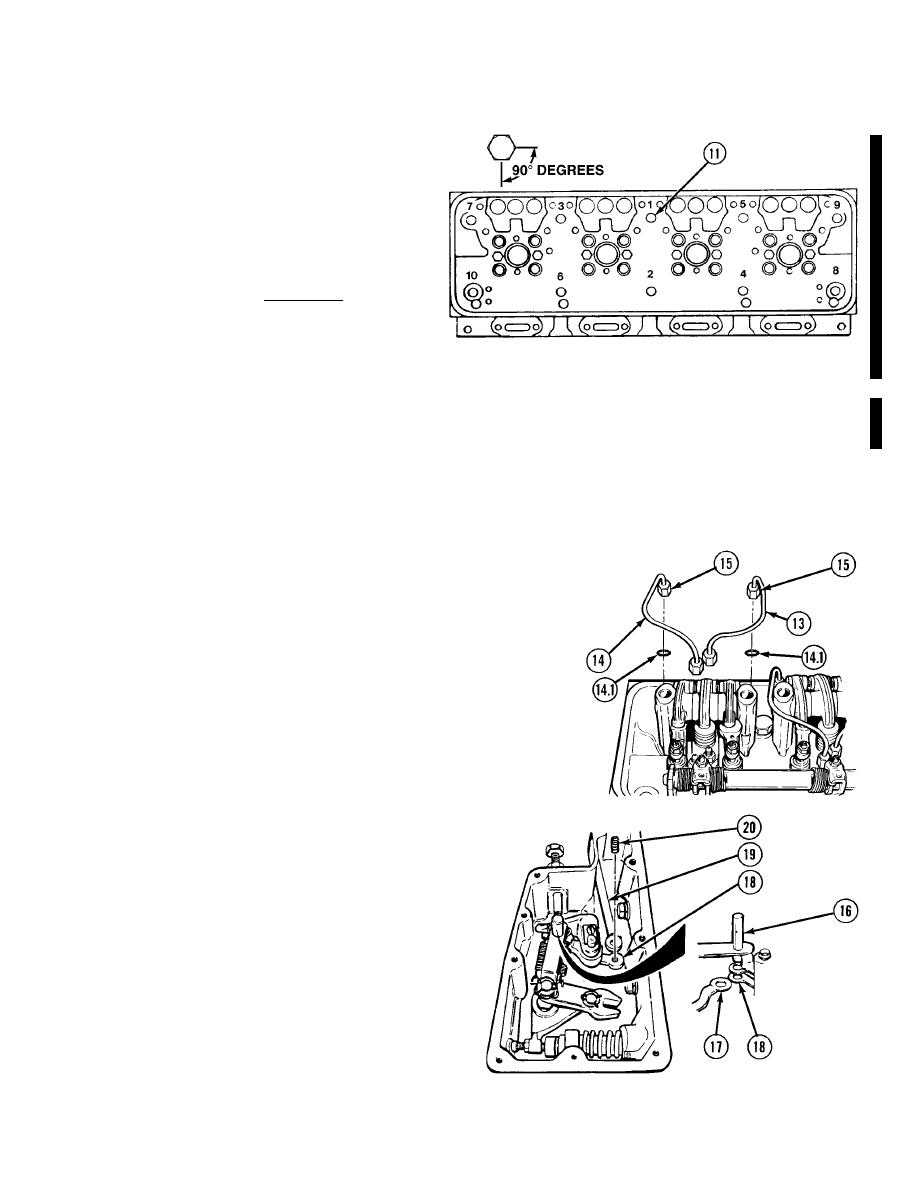

(8)

Gradually tighten ten cylinder

head screws (11), in 50 lb-ft (68

NSm) increments, to 150 lb-ft (204

NSm) in the sequence shown.

Hold the wrench at this torque for

2 to 3 seconds to allow bolts to

turn while the compression seals

yield to their crushed thickness.

CAUTION

While performing step (8.1) do

not loosen more than one bolt at

a time. Failure to comply may

cause damage to equipment.

NOTE

For ease in carrying out the procedure below, it may be convenient to premark a

socket with four marks 90 degrees apart. At the start of each turn, mark the head

with a grease pencil at one mark on the socket and turn to the next mark.

(8.1) After completing step (8) perform the following in the same sequence, beginning with cylinder

head screw #1 and continuing one cylinder head screw at a time. Back off cylinder head screw

until loose (at least one-half turn.) Retighten to 100 lb-ft (136 NSm), plus a turn of an additional

90 degrees. Try to turn the cylinder head screw in a single arc with one pull of the wrench.

Then proceed with cylinder head screw #2, etc.

NOTE

O-rings must be installed dry. Do not apply oil.

(9)

Install eight fuel tubes (13 and 14) and

sixteen O-rings (14.1).

(10)

Tighten 16 nuts (15) to 160 lb-in (18.1

NSm) using fuel line nut wrench.

NOTE

Fuel rod is installed through cylinder

head.

Left and right bank fuel rods are installed

differently. Step (11) covers installation of

left bank; step (12) covers installation of

right bank.

(11) Lift connecting pin (16) 3/4-in. (19 mm).

Install left bank fuel rod (17) to control

link operating lever (18).

(12) Install right bank fuel rod (19) to control

link operating lever (18). Install

screw (20).

Change 4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |