|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM

FUEL INJECTION PUMP

REPAIR .(CONTINUED),

K Inspect face gear for damage, worn teeth or guide slot, and

INSPECTION AND REPAIR

cracks. Replace if necessary.

A Inspect hydraulic head for cracks. Replace if necessary.

Inspect thrust washer for scoring, grooving, or wearing.

L

Replace if necessary.

B Use magnifying glass to inspect hydraulic head for scored,

pitted, eroded, or damaged delivery valve seat. Refinish

M Inspect plunger button for scoring, excessive wearing, or

seat with lapping tool

and lapping compound

uneven wear pattern. Replace button if necessary. Refer to

(item 22, Appx C).

p 4-12 for button selection procedure.

Inspect hydraulic head for damaged discharge fitting

c

Inspect plunger retaining rings for bends or breaks.

threads. Replace fitting. Torque fitting to 70-75

Replace if necessary.

D Inspect delivery valve assembly for scored, pitted, eroded,

O Inspect fit of spring ring in ring groove. Replace spring ring

or damaged valve or body seat, or cracked body. Replace

if loose.

delivery valve assembly.

Inspect gear retainer for excessive bending. Replace if

P

Inspect delivery valve assembly for leakage. Refer to test

E

necessary.

on p 4-11. Replace if

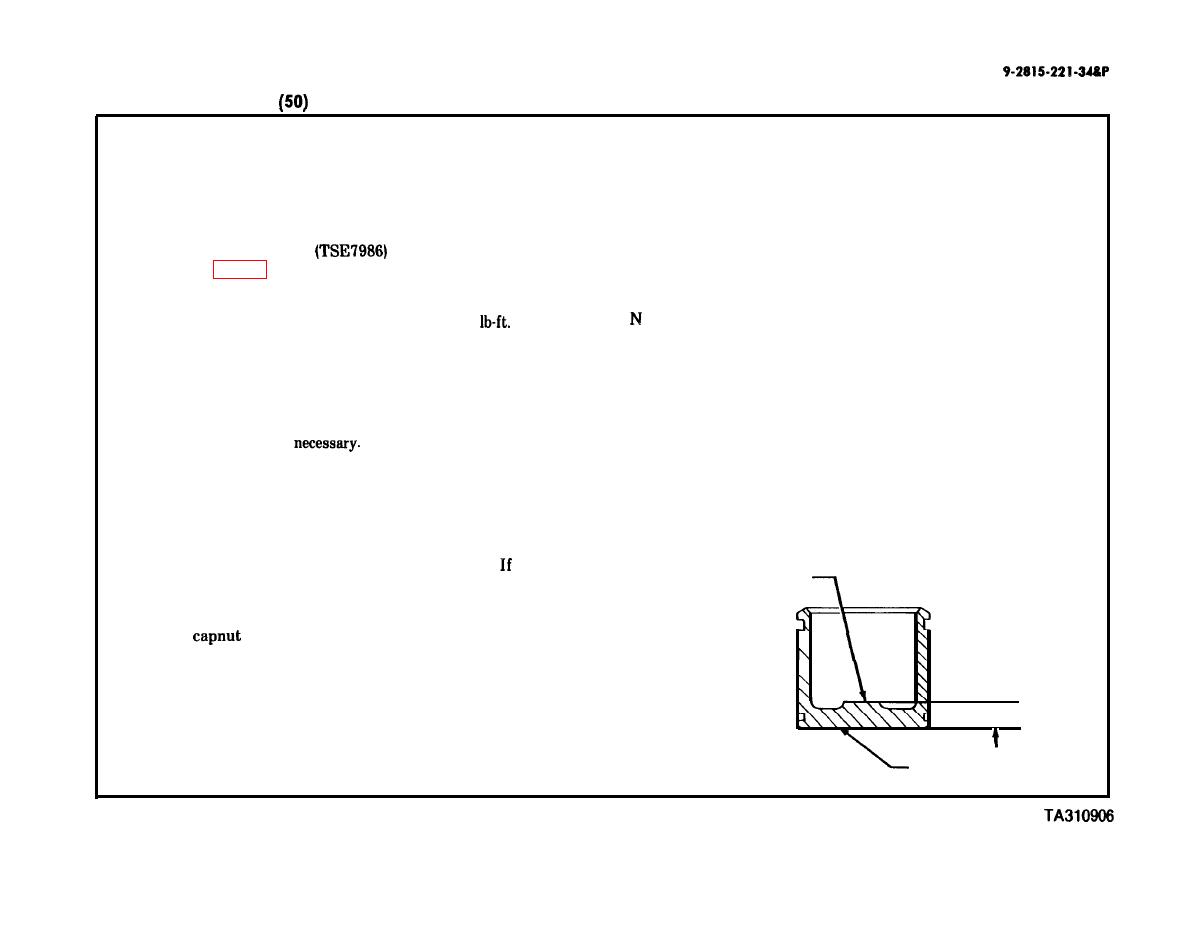

Q Inspect tappet for wear at button pad at cam contact surface.

F

Inspect delivery valve spring and plunger spring for cracks,

Wear on cam contact surface must not exceed .002 inch.

nicks, or wear. Replace if necessary.

Distance between button pad and cam contact surface must

be .207 -inch minimum as measured with a micrometer.

G Use magnifying glass to inspect plunger and metering sleeve

for fine scratches, scuff marks, or dull areas on lapped sur-

faces. These conditions indicate contaminated fuel. condi-

BUTTON PAD

tions exist, check fuel filtering system. Head should not be

replaced due to physical appearance of plunger or sleeve.

H Inspect

for cracks, damaged threads, or damaged

\

sealing surface. Replace capnut if necessary.

\

Inspect delivery valve holder for damaged threads or lower

I

+

gasket sealing surface. Replace holder if necessary.

.207" MIN.

Inspect plunger guide for cracks, breaks, or excessive play

J

between plunger guide and plunger shank. Replace if

CAM CONTACT SURFACE

necessary.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |