|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

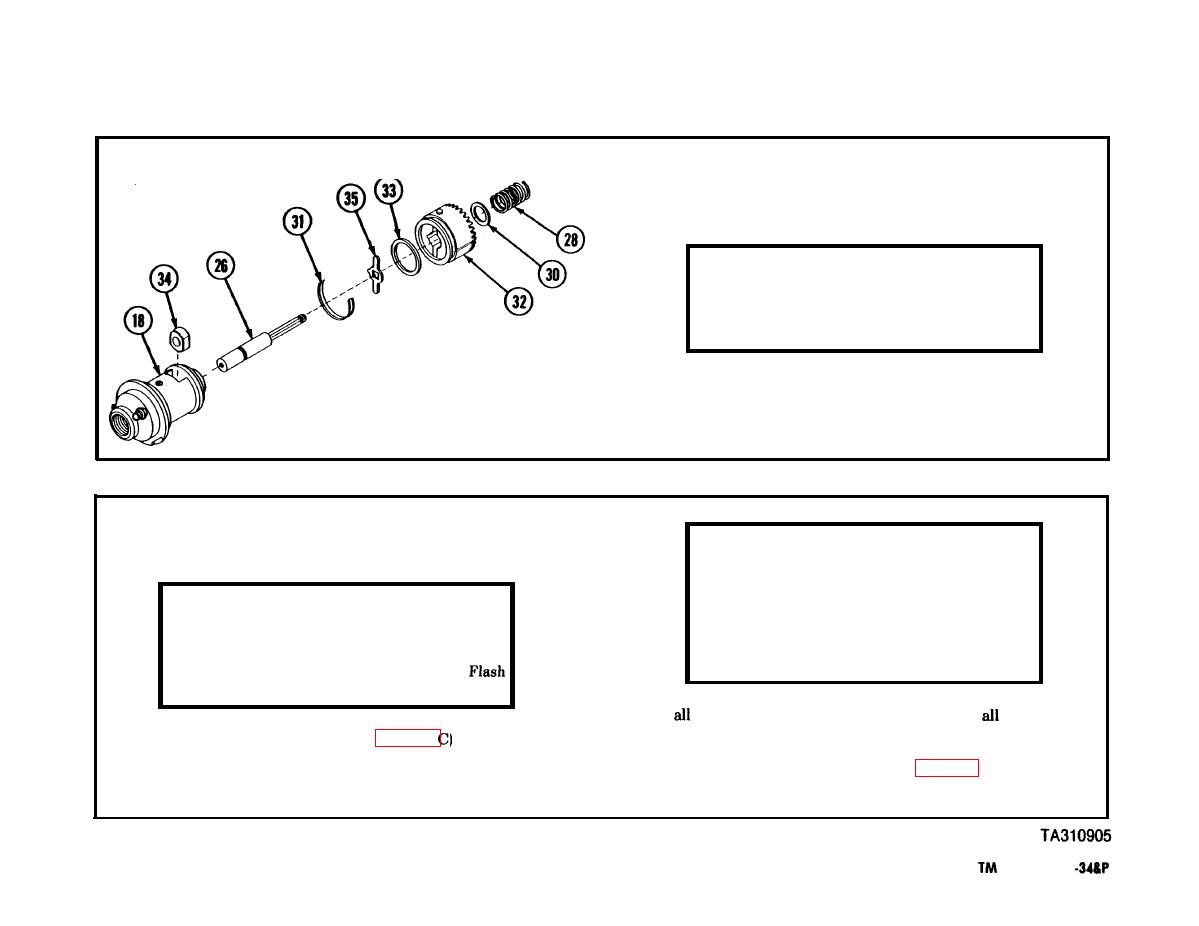

FUEL INJECTION PUMP (50) REPAIR (CONTINUED)

N Remove upper spring seat washer (30) and plunger spring (28).

O Remove gear retainer (31) and face gear (32) from head (18)

and thrust washer (33).

CAUTION

Plunger (26), metering sleeve (34), and hydraulic

head (18) are mated parts and must be kept

together.

P

Remove plunger (26) and metering sleeve (34) from hydraulic

head (18).

Q Remove plunger guide (35) from plunger (26).

WARNING

CLEANING

Particles blown by compressed air can be

dangerous. Direct air stream away from user and

WARNING

other personnel in the area. Compressed air used

for cleaning will not exceed 30 psi. Use only with

Dry-cleaning solvent used to clean parts is poten-

effective chip-guarding and protective equipment

tially dangerous to personnel and property. Do

(goggles/shield and gloves).

not use near open flame or excessive heat.

point of solvent is 138 "F.

B Dry

parts with compressed air making sure

hydraulic

head ducts are blown out.

A

Use dry-cleaning solvent (item 8, Appx

to thoroughly

clean all metal parts.

C Apply film of clean lube oil (item 16, Appx C) to all parts

prior to assembly.

9-2815-221

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |