|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

*TM 9-2815-213-34

CHAPTER 3

REPAIR INSTRUCTIONS

Section I. General

order of engine reassembly.

3-1. Procedures

c. The

instructions

covering

cleaning,

a. The repair instructions contained in chapter

inspection, and repair are in addition to the general

cover the disassembly, cleaning, inspection, repair,

maintenance requirements of Chapter 2.

test, adjustment, and assembly components and

d. Standard parts kits used in repair are

component assemblies.

described in Appendix B.

b. The procedures also provide for the

installation of repaired components that permits a logical

Section II. Repair of Cylinder Block

3-2. Disassembly

a. Pipe Plugs. Remove all pipe plugs from and

water passages.

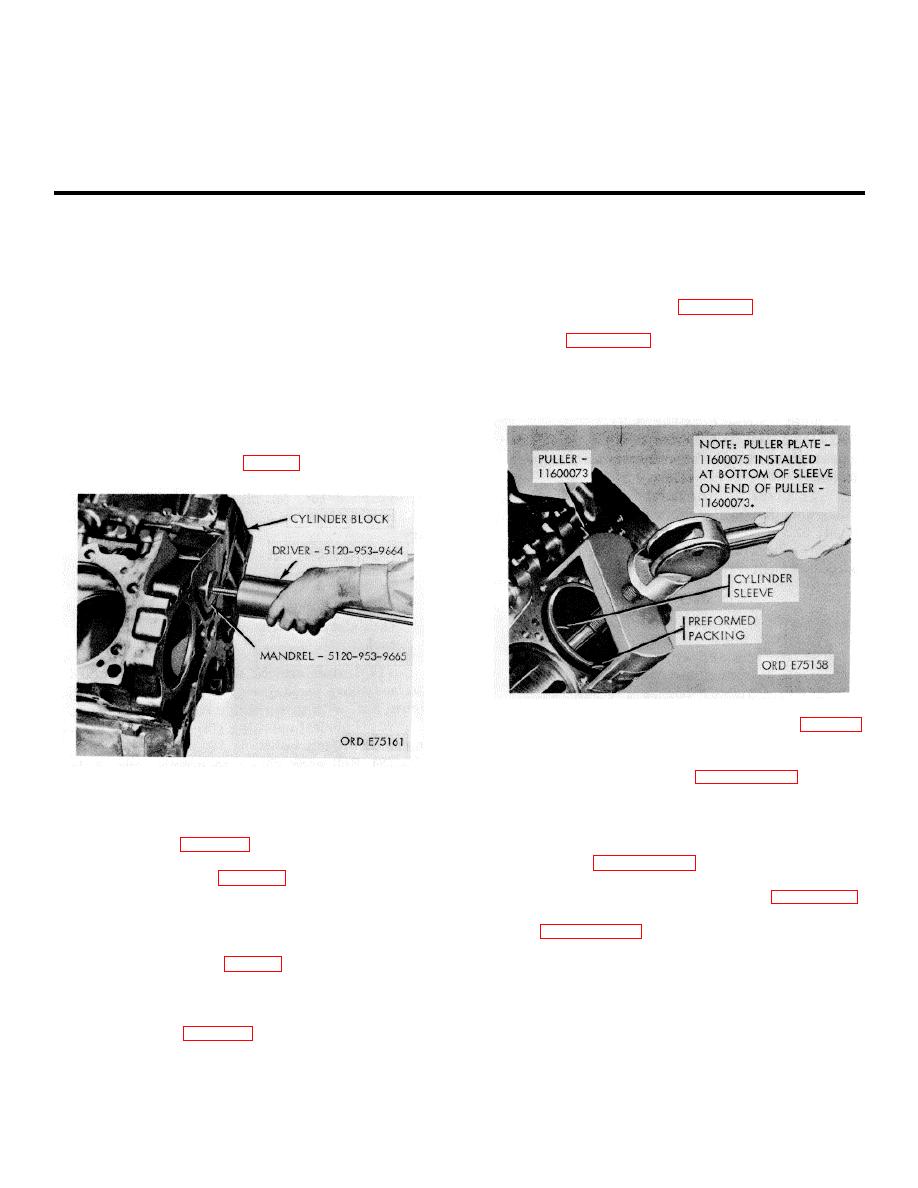

Figure 3-2. Cylinder sleeve removal

Using cylinder sleeve puller and plate (10 and 11, fig. B-

28) remove and discard sleeve(s).

3-3. Cleaning

Figure 3-1. Camshaft bushing removal.

Clean block in accordance with paragraph 2-5. Clean all

water and oil passages with compressed air.

NOTE

3-4. Inspection

Remove camshaft bushings only if

a. Camshaft Bushings.

inspection (para. 3-4) indicates need for

(1) Visually inspect the five bushings in

replacement. Using camshaft driver and

accordance with paragraph 2-6.

mandrel (7 and fig. B-28), remove and

(2) Check the ID of the bushings against limits

discard bushing(s).

specified in repair and rebuild standards (para. 3-180).

Replace any bushing worn beyond specified limits.

Using camshaft driver and mandrel (7 and 8,

Refer to paragraph 3-2.b. for bushing removal.

fig.B-28), remove and discard bushing.

b. Cylinder Sleeves.

(1) Visually inspect each sleeve for cracks and

scratches. Replace sleeve if cracks or heavy scratches

NOTE

are present.

Remove cylinder sleeves only if

inspection (para. 3-4) indicates need of

replacement.

3-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |