|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

*TM 9-2815-213-34

drive gear from camshaft gear, and remove compressor.

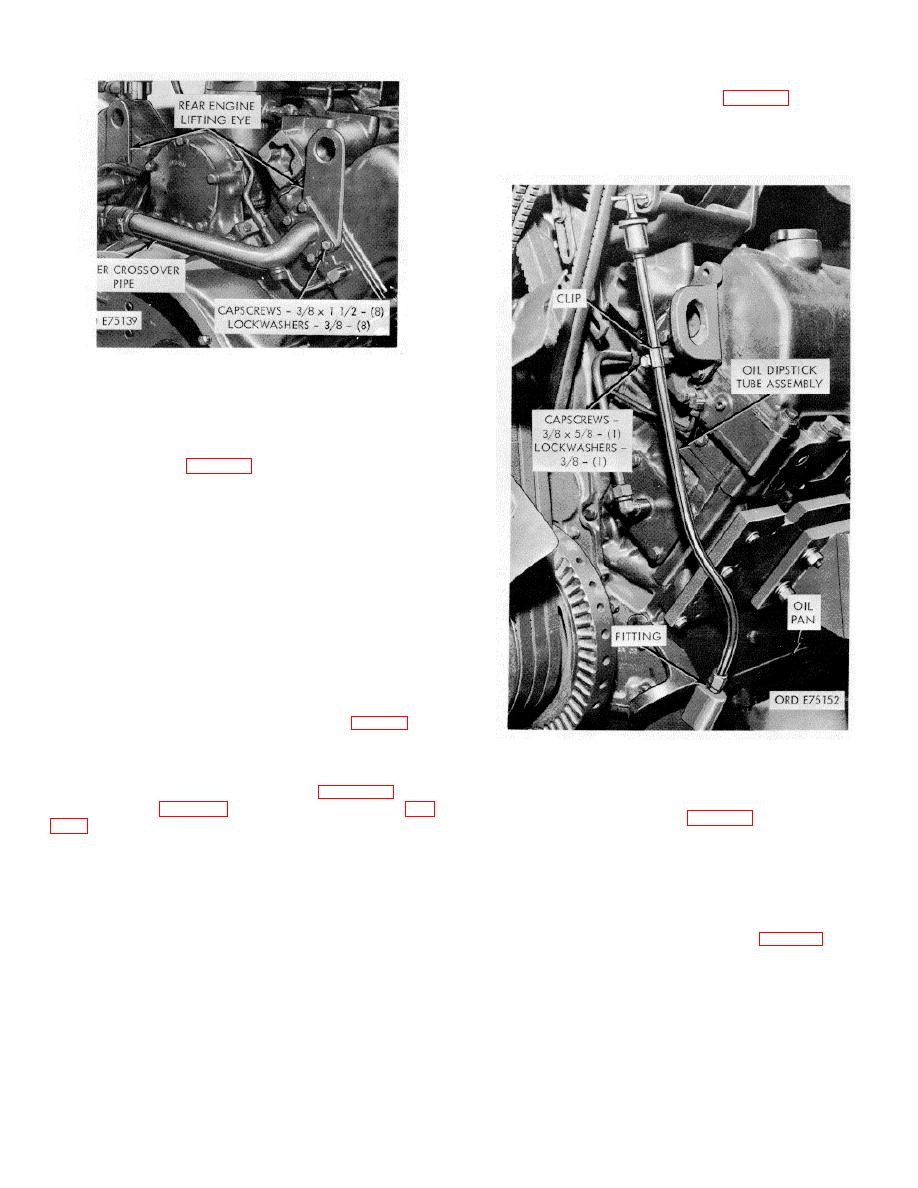

(1) Remove capscrew and lockwasher securing

tube clip to engine block.

(2) Disconnect tube at oil pan fitting and remove

tube.

Figure 2-10. Water crossover pipe and engine lifting

eyes--removal/installation.

rear end of each cylinder head and remove cross-over

with flexible metallic drain return line at tached.

(6) Loosen two capscrews, securing fuel pump

support bracket (32, fig. B-18), to engine block.

(7) Remove four capscrews, lockwashers, and flat

washers, securing fuel pump to air compressor housing

and support bracket.

(8) Slide support bracket towards front, pull pump

towards front and remove from compressor. Remove

gasket.

(9) Remove two capscrews, lockwashers, and flat

washers securing bracket to block and remove bracket.

NOTE

The fuel pump is driven through a

freefloating coupling between the pump

and compressor. Insure that coupling

and plate are removed with pump.

(1) Disconnect coolant input and output lines at

Figure 2-11. Oil dipstick tube assembly-

compressor.

removal/installation.

(2) Disconnect air discharge line at compressor.

(3) Remove six capscrews (10, fig. B-25) and

2-11. Internal Components

lockwashers (9, fig. B-25) securing rear support (8, fig.

(1) Right Head Cover.

(4) Remove support and gasket.

(a) Remove ten capscrews, lockwashers, and plain

(5) Pull compressor and drive assembly toward front

washers securing cover to head.

of engine, to disengage compressor

(b) Remove cover and gasket.

(2) Left Head Cover.

(a) Loosen hose clamp securing breather tube to

crankcase breather and pressurizing unit (fig. 2-13).

(b) Remove breather tube from unit.

2-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |